High-GWP HFCs in Foam Sector Overview

This report presents insights from speakers and panelists on low-GWP alternatives for the foam sector, including flammable and non-flammable options. It discusses the current status of large enterprises and SMEs in adopting these alternatives, as well as challenges related to safety, energy efficiency, cost, and technology adoption in the industry.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

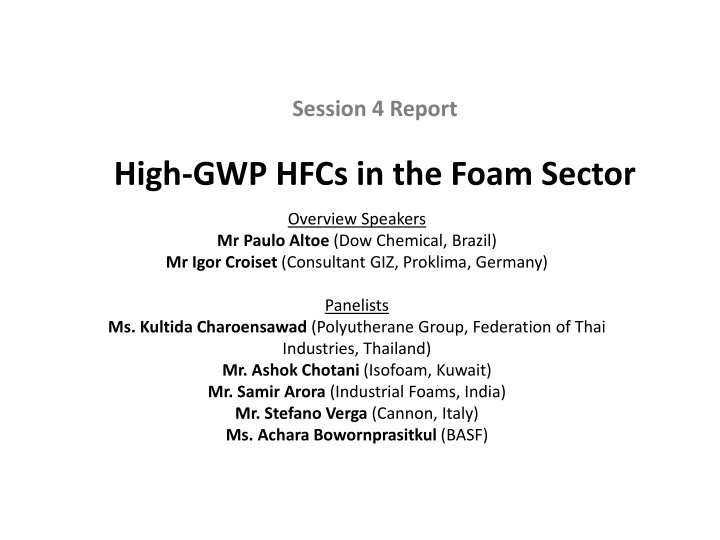

Session 4 Report High-GWP HFCs in the Foam Sector Overview Speakers Mr Paulo Altoe (Dow Chemical, Brazil) Mr Igor Croiset (Consultant GIZ, Proklima, Germany) Panelists Ms. Kultida Charoensawad (Polyutherane Group, Federation of Thai Industries, Thailand) Mr. Ashok Chotani (Isofoam, Kuwait) Mr. Samir Arora (Industrial Foams, India) Mr. Stefano Verga (Cannon, Italy) Ms. Achara Bowornprasitkul (BASF)

Summary of Low-GWP Alternatives for the Foam Sector Flammable options Hydrocarbons (HCs, i.e. pentanes and isobutane) Oxygenated hydrocarbons (HCOs) such as methyl formate and methylal Non-flammables CO2 HFOs

Current Status Large enterprises Hydrocarbons (pentanes and isobutane) CO2 for applications where thermal insulation is not critical HCOs/HFCs as co-blowing agents SMEs CO2 Preblending of hydrocarbons HFCs with high water%

Challenges Safety when HCs and HCOs used: Premixed blends + reformulation Energy efficiency when CO2 is used: Co-blowing with HFOs Cost when HFOs are used: Co-blowing with CO2 High ambient temperature when HC premixes are used: Need to properly storage, transport and handling of premix containers Time constraint to phase-in HFOs: The industry needs more time to large-scale prove the HFO technology (e.g. long-term stability) In-situ spraying: HFO/CO2 co-blowing can help, but it does not fundamentally solve the problem