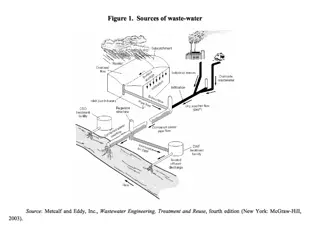

Holistic Approach to Wastewater Management and Treatment Processes

Covering topics like effluent standards, disposal methods, biological treatment, advanced treatment, and industrial wastewater treatment, this comprehensive resource by Rajesh Bhagat provides valuable insights into the sustainable management of wastewater. With a focus on practical applications and design principles, this content is a must-read for professionals and students in the field of environmental engineering.

Uploaded on Mar 12, 2025 | 2 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

PE-IV Wastewater Treatment Rajesh Bhagat Achievement: Selected Scientist, NEERI-CSIR, Govt. of India. BE (Civil Engg) GCOE, Amravati MTech (Env. Engg) VNIT, Nagpur GATE Qualified Three Times. UGC - NET Qualified in First Attempt. In 2020, Recognized by SWAYAM, NPTEL & IIT: 1) Discipline Star 2) NPTEL Believer Topper of PhD Course Work at UGC-HRDC, RTMNU Nagpur. Selected Junior Engineer, ZP Washim. Three Times Selected as UGC Approved Assistant Professor: 1) Assistant Professor, PCE, Nagpur. 2) Assistant Professor, Cummins College of Engg. for Women. 3) Assistant Professor, YCCE, Nagpur. Mobile No.:- 8483002277 / 8483003474 Email ID :- rajeysh7bhagat@gmail.com

UNIT-I 1) Holistic approach to wastewater management, 2) Effluent & stream standards, 3) wastewater characteristics and their significance, 4) disposal methods for wastewater on land and in water and its impact, 5) self-purification of streams 2

UNIT-II 1) Preliminary Treatment Processes 2) Primary Treatment Processes 3) Screens 4) Grit Chamber 5) Primary Settling Tank 6) Principles, Types & Designs. 3

UNIT-III 1) Secondary treatment processes & units 2) Concepts in biological treatment, bacterial growth 3) Activated sludge process 4) Trickling filter 5) Principles, types. Simple design problems / exercise 4

UNIT-IV 1) Other Biological Treatment Units 2) Aerated Lagoons 3) Stabilization Ponds 4) Up-flow Sludge Blanket Reactors 5) Sludge Digester. 5

UNIT-V 1) Need of Advanced Treatment 2) Removal of Trace Organics 3) Micro Screening and Control of Nutrients 4) Nitrification and De-nitrification 5) Removal of Phosphorus. 6

UNIT-VI 1) Treatment Alternatives for Industrial Wastewater 2) Volume Reduction 3) Strength Reduction 4) Equalization Tank 5) Neutralization Tank 6) Specific Industrial Wastewater Treatment for Paper and Pulp Industry, Sugar Industry, Distillery Industry, Dairy Industry, Textile Industry. 7

References:- 1. S.K. Garg, Environmental Engineering Vol-2, 2010, Khannna Publication 2. G.S. Birdie, Water Supply & Sanitary Engineering, Dhanpat Rai Pub Company 3. M.J. Machghee, Water Supply & Sewage, McGraw Hill Publication. 4. P N Modi, Sewage Treatment & Disposal & Wastewater Engg., Rajsons Publications Pvt. Lts 5. B.C. Punmia, 2010, Wastewater Engineering, Laxmi Publications (P) Ltd., New Delhi. 6. M. N. Rao, 2007, Waste Water Treatment, Oxford and IBH publishing. 7. Patwardhan, 2008, Industrial Wastewater Treatment, PHI learning Pvt. Ltd. 8. G.L. Karia and R. A. Christian, 2006, Wastewater Treatment, PHI learning Pvt. Ltd. 9. Metcalf and Eddy, 2006, Wastewater Treatment Disposal and Reuse, Tata McGraw Hill publishing company Ltd.

Industrial Wastewater Treatment:- a) Characteristics of industrial sewage differ considerably from domestic sewage. b) Characteristics of industrial sewage vary with the type of industry and even in the same type of industry they vary according to the process involved. c) Industrial sewage contains chemical pollutants & toxic substances in large proportions. d) Industrial sewage needs proper treatment before disposal. e) Various industries are classified based on characteristics of sewage. 1) Food & food processing industries like sugar, canning, dairy, fermentation, etc. 2) Chemical processing industries like chemical manufacturing, paper & pulp, tannery, textile, rubber, electroplating, etc. 3) Mineral Product industries like iron, steel, oil, petroleum, coal, coke, gas, etc. 4) Other industries like atomic power plants, etc.

General Characteristics of Industrial Wastewater:- 1) Industrial sewage has a high proportion of suspended solids, dissolved organic and inorganic solids, BOD, alkalinity or acidity, etc. 2) Contaminants or constituents are usually not in the same proportion as they exist in a normal domestic sewage. 3) Industrial sewage may also contain toxic substance. Various constituents present in industrial wastewater: Organic substances depletes DO of river. Inorganic substances are undesirable for plants growths in water body & which render the water body unfit for further use. Acids & Alkalies cause serious problems in the operation of treatment units. Color producing substances imparts objectionable color. Oil & Grease hinder self-purification of river. Toxic Substances greatly affect the flora & fauna of water body.

Toxic Substances in Industrial Sewage:- Industry Toxic Substances Fertilizers Arsenic, Cyanide, Ammonia Coke Ovens Phenol, Cyanide, Thiocyanate, Ammonia Metallurgical Heavy Metals like Copper, Zinc, Cadmium Electroplating Chromium, Cadmium, Zinc, Copper Petrochemicals Phenols, Heavy Metals, Cyanide

Processes Involved in Industrial Wastewater Treatment:- 1) Equalization 2) Neutralization 3) Physical Treatment 4) Chemical Treatment 5) Biological Treatment Factors affecting selection of processes: Flow, Concentration of pollutants, Presence of non biodegradable organics, toxicity, etc

Equalization:- Holding the sewage for predetermined time in a continuously mixed tanks so as to get sewage of uniform character and at uniform rate. 1) To facilitate maintenance of uniform flow rate in the treatment units, flow equalization is used. 2) To overcome the operational problems caused by flow variation and improves performance of the treatment plant. 3) For dampening the flow rate variations so that a constant or nearly constant flow rate is achieved. For dampening the fluctuation in pollutant concentration in the incoming wastewater to avoid shock loading on the treatment system. 4) To provide continuous feeding to the treatment system when the wastewater generation is intermittent. 5) To control pH fluctuations or to control toxic concentration in the feed to the biological reactor. 6) To control the discharge of industrial effluent in to the sanitary sewers.

Neutralization:- 1) This necessary when the sewage is either excessively alkaline or acidic and it is achieved by the addition of either acid or alkali respectively. 2) This may be done either in the equalization tank where possible, or else in a separate neutralization tank.

Physical Treatment:- 1) Physical treatment of industrial sewage is similar to primary treatment of domestic sewage. 2) Various processes that are included in physical treatment of industrial sewage are : Screening, Sedimentation & Floatation. Floatation: - 1) Floatation is adopted to remove the finer particles from the industrial sewage. 2) Creating fine air bubbles in the sewage tank by introducing air into tank from the bottom. 3) Rising air bubbles attach themselves to the suspended particles thereby increase their buoyancy and lift them to the liquid surface from where these are removed by skimming.

Dairy Industry:- The volume of sewage from different dairies may vary from 6 to 10 litres per litre of milk processed depending on the processes used, care taken, quality & quantity of water used. Milk product: butter, ghee, cheese, chhana, condensed milk, powdered milk, baby food & ice-cream. Sewage from dairies include wash water from milk cans, tanks, bottles, equipment, pipe line and floor. Methods of Treatment: 1) Preliminary Treatment: Screens & Grease Traps 2) Primary Treatment: Dilution, Lagooning 3) Secondary Treatment: Oxidation ditches & Oxidation Ponds

Sugar Industry:- 1) In India, most of sugar industries operate 4 to 8 months just after harvesting of the sugar canes. A large volume of waste of organic nature is produced production. 2) The fresh effluent from sugar industries, decomposes rapidly after few hours of stagnation. 3) The rapid depletion of oxygen due to biological oxidation followed by anaerobic stabilization of the waste causes a secondary pollution of offensive odor, black color and fist mortality. 4) Judicious use of water in various plant practices, and its recycle, wherever practicable, will reduce the volume of waste to a great extent. Volume of mill house waste can be reduced by recycling the water used for splashing. 5) Proper control of operations also reduces the organic load of waste. 6) Disposal of the effluent on land as irrigation water is practiced in many sugar mills, but it is associated with odour problem. 7) The reasonable COD/BOD ratio of the mill effluents indicate that the waste is amenable to biological treatment. However, ASP and TF is not too efficient even at a low organic loading rate.

Sugar Industry:- 1) The reasonable COD/BOD ratio of the mill effluents indicate that the waste is amenable to biological treatment. However, ASP and TF is not too efficient even at a low organic loading rate. 2) Anaerobic treatment of the effluent, using both digester and lagoons, have been found to be more effective and economical. Further reduction of BOD can be accomplished in aerobic waste stabilization pond. 3) Where sufficient land is available, a two stage biological treatment, with anaerobic lagoons followed by aerobic waste stabilization pond is recommended for Indian conditions. 4) The mill effluent, however is to be pretreatment primarily in bar screens and grease trap. The flow sheet for the complete treatment of the sugar mill waste. 5) Overall BOD reduction must be 90%

1) What is the difference between sewage and industrial waste? 2) What are the measures to minimize the concentration of industrial waste? 3) Explain the characteristics of industrial wastewater? 4) What is the significance of Industrial wastewater treatment? 5) Discuss in brief equalization, neutralization, proportioning & floatation? 6) Explain the various chemical processes involved in treatment of industrial wastewater?