Implementing QA/QC Systems for Energy Supply Chain Improvement

Explore a case study on implementing QA/QC systems in independent energy operators' supply chains. Learn about the foundation of continual improvement, quality assurance methodologies, and timelines for quality improvement plans.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Case Study: Implementing QA/QC Systems in an Independent Energy Operator s supply chain

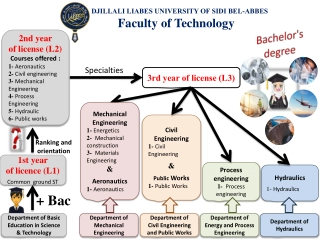

Contents Sandaig Engineering; Global Market QA/QC Consultancy Experience Foundation PDCA Cycle for Continual Improvement Plan for Supply Chain Quality Improvement Implementation Timeline What Good Looks Like When We Get It Right

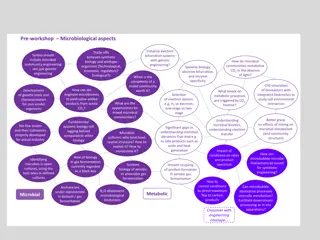

PDCA Cycle : The Foundation of Continual Improvement Planning Quality and Technical Requirements Quality Assurance System Project Plans Procedures Training Quality Assurance Methodology This simple approach to Quality can be applied equally to any process. Improvement (Act) Nonconformance Corrective Action Lessons Learned Change Control Training Execution (Do) FEED Design Purchasing Construction Material Control Measurement (Check) Project Reviews Quality Audits Inspection Key Performance Indicators

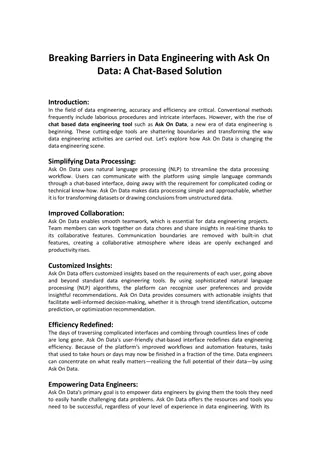

Plan For Supply Chain Quality Improvement Contract Award /Mobilisation Pre-Qualification & ITT Preparation Tender Evaluation & Selection/RTA Interface Management Procurement Strategy Activities Activities Activities Activities Activities QPRs HSSE Plan Tender Evaluation Contractor Qualification CIP Category Reporting/KPIs MSID Site Assessment/Audit HSSE Risks Tender Package Audits Personnel Competency Equipment Criticality Assessment (ECA) Final agreement HSSE T&Cs/Exhibits Forums Reporting requirements Agreement Award Tender Evaluation Plan Services Criticality Assessment (SCA) Quality KPIs Quality Capability Assessment (Desktop and physical Audit) QA/QC Contract Exhibit Quality Risk Category Quality Plan Tools Tools Tools Tools QA in QPR process Pre-mob checklist CIP Categorisation Model Audit protocol Contractor Scorecard Third Party Inspection QA/QC Questionnaire Supplier NCR s Port and Temp equipment ECA template QA/QC RFP Scorecard Supplier Contract Audits SCA template PQC QA/QC codes * Quality Segments Inspection and Test Plans

Case study QA/QC Deliverables 2 to 3 year timeline Equipment criticality phase 2 & Beyond Maturing of receiving inspection Year 3 Deliverables Supplier NCR s on Insight O & G UK SQS process QA/QC in R&W RFP Steady state supplier audits Ariba supplier certification QA/QC KPI s within QPR s Contract exhibit by commodity questionnaire by commodity Roll out Temp and portable procedure Equipment Criticality Pilot (Valves) Excel and word supplier NCR Process Year 2 Deliverables Roll out Service criticality First supplier audit Reinstate receiving inspection First QA/QC RFP evaluation QA/QC contract exhibit 3rdparty inspection QA/QC within QPR s Draft service criticality procedure Draft temp and portable procedure Draft equipment criticality procedure Understand current Project QA/QC processes Q4 Year 1 Deliverables On board 2ndQA Engineer Q4 Year 1 Understand where we are (Plan) Q1 and Q2 Year 2 Implement the basics (Plan/ Do) Q3 and Q4 Year 2 on the basics (Do/ Check) Year 3 Steady state (Do/ Check/ Act)

QA/QC What Good Looks Like Documentation Pre contract award Process in place for communicating and receiving certification/ documentation: Technical specifications Interface/ bridging document Equipment Criticality Surveillance Assessment Hired and Transportable Equipment Service criticality has taken place on supplier by technical, QA and HSE personnel QA questionnaire has been issued, desk top audit completed and supplier scored If required, a physical on site audit has taken place What's in the Contract? Pertinent commodity QA clauses Pertinent inspection or certification requirements Offshore and onshore Competency requirements

QA/QC What Good Looks Like Delivery Monitoring the Contract Product Supplier aware of, and can provide certification as per Product Quality Codes Pertinent Inspection and Test plans are in place and supplier knows what is required for inspection and release Hired and transportable equipment process understood and being followed Service Work packs in place in a timely manner Competency process in place and competent personnel supplied offshore Hired and transportable equipment process understood and being followed Building a strong relationship with supplier QA function Timely response to NCR s Adherence to supplier s own internal audit schedule Supplier following their own QA Improvement plan Supplier included in audit schedule

And When We Get It Right Giving suppliers accurate and correct information to ensure the correct equipment is delivered with the correct certification and is fit for purpose ..first time. Valve and plant integrity. Plant & Equipment operating as planned. HSE risk minimized. No lost production. Happy Shareholders.

Contact Us sandaigengineering.com robbie@sandaigengineering.com +44 (0) 7542 562269