Improving Food Safety: HACCP Plan Preparation and Implementation

Enhance your knowledge on drafting HACCP plans and implementing good hygiene practices with this training course. Learn about hazard analysis, determining CCPs, management commitment, assembling teams, and defining study scope.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

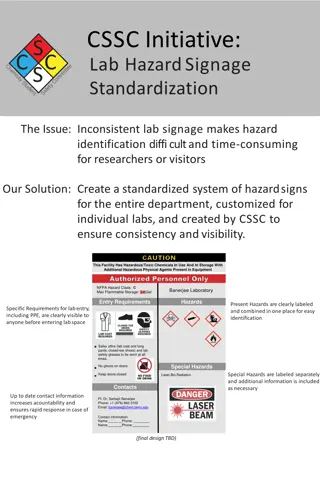

Project: Technical assistance to improve implementation of food safety standards and disease crisis preparedness Training cource:Training on step-by-step drafting/preparation of HACCP plan and implementation of good hygiene practices and HACCP principles - Preparatory stages of HACCP and Principles 1 and 2: hazard analysis and determining CCPs Lecturer: Prim. D-r Lenche Jovanovska Date: 10, 14, 17,21, 24 and 28 of Marth 2022 Place: Nicosia, Cyprus Project funded by the European Union Aid Programme for the Turkish Cypriot community, implemented by NSF Euro Consultants Consortium Disclaimer: This presentation has been produced with the financial support of the European Union. Its contents are the sole responsibility of NSF Euro Consultants Consortium Contractor, and do not necessarily reflect the views of the European Union.

Preparatory stages - Objective By the end of this presentation you should be familiar with the preliminary steps set up in the Codex Alimentarius, Annex to CAC/RCP 1-1969 (Rev. 2020) for carrying out and implementing a HACCP system

Preparatory stages 1. Management commitment (FSC!) 2. Assemble a team 3. Scope of the study 4. Description of the product and intended use 5. Description of the process flow 6. Process flow verification Included in the Commission Notice on FSMS as preliminary activities

1. Management commitment The executive and management teams must declare their willingness to achieve food safety: By setting up goals; By providing resources to build, maintain and implement the HACCP plan; By reviewing food safety reports; By taking direct action when something goes wrong Food Safety Culture Amendment of regulation (EC) No 852/2004

2. HACCP Team HACCP team: That has the appropriate product specific knowledge and expertise to develop an effective food safety plan Multidisciplinary members HACCP knowledge within the company or with external help Defined functions

3. Scope of the study The scope of the study is a clear definition of what the HACCP plan will cover. Description of the product groups (if more than 1). Beginning and end of the study. Types of hazards studied in the HACCP plan: C / B / P and sometimes A

4. Product description List of ingredients, raw materials: - Complete list of ingredients, food additives, allergens Packaging lists - Materials, migration certificates, usage and storage conditions End product description

4. Product description: Packaging Packaging material certificates: Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food Regulation (EC) No 10/2011 on plastic materials (Declaration of Compliance, DoC) Specifications about the use of the material or article: type or types of food intended to be put in contact; time and temperature of treatment and storage in contact with the food; ratio of food contact surface area to volume used to establish the compliance of the material or article.

4. Product description: End Product Common name: Protected name, health claim Intended use: Ready to eat, instructions for use Packaging description: vacuum packed, modified atmosphere Shelf-life Storage and distribution: where will it be used/sold? Labelling requirements: general and specific Specific use/group of consumers known to be especially vulnerable, e.g.: slimming, low in salt, free from allergens

4. Product description: End Product Physical and chemicals characteristics pH awand/or salt concentration

5. Description of the process flow A flow diagram that covers all steps of the operation, including steps preceding and following the specified operation Flowchart and/or listing the process steps: Describe the process using text, before starting with the flowchart Must have a starting and a finishing step. What happens first? All steps are fed and linked to a prior step: What happens next? (Remember: raw materials, ingredients, intermediates, packaging materials etc. entering the flow) Each step is described in simple and descriptive words in the flow diagram The whole process is connected

6. Process flow verification On-site confirmation of the flow diagram Determine that the flow diagram is aligned with actual operations Is the process accurately described? Are there any hidden steps? Are there any by-passes or loop steps missing? Are there any steps involving recycling or reworking? Are those documented? Are there any connected processes: by-products, feed

CONCLUSION These preliminary steps are recommended (not a legal requirement) before the hazard analysis (Principle 1 of HACCP) is applied. Facilitates the hazard analysis, e.g. - the description of the end product gives relevant information for food safety, - the flow diagrams can be used as a basis for evaluating the possible occurrence, increase, decrease or introduction of food safety hazards.

Principles 1 and 2: Principles 1 and 2: hazard analysis and determining CCPs Objectives: Terminology Current tools Field applications Objective of session: To gain an understanding of hazard analysis and determining CCPs by the traditional method and also using alternative methods.

Hazard analysis and CCPs Article 5, Regulation (EC) No 852/2004 1. Food business operators shall put in place, implement and maintain a permanent procedure or procedures, based on the HACCP principles. 2. The HACCP principles referred to in Paragraph 1 consist of the following: (a) identifying any hazards that must be prevented, eliminated or reduced to acceptable levels; (b) identifying the critical control points at the step or steps at which control is essential to prevent or eliminate a hazard, or to reduce it to acceptable levels

The Field Wide variation on approaches on hazard analysis and CCP determination (and their efficiency). Knowledge, experience, common sense and flexibility required. Many sectors or FBOs have difficulties in implementation. The role of National Guides: scientific and detailed hazard analysis FBOs focus on implementation.

Hazard and Risk HAZARD: A biological, chemical or physical agent in, or condition of, food with the potential to cause an adverse health effect. The cause RISK: A function of the probability of an adverse health effect and the severity of that effect, consequential to a hazard in food. The consequence Acceptable risk safe and wholesome food

Hazard identification The HACCP team should list all potential hazards Brainstorming process Diversity of HACCP team needed Then, identify where these hazards are reasonably likely to occur at each step Source/Reason should be described

Hazard analysis (risk evaluation) Probability / Severity Risk evaluation initially screens the related risk and a logical approach (i.e. a decision tree) further specifies the final choice of steps and control measures.

Hazardanalysis: Factors to consider Full knowledge of the Product (raw materials, actual process, intermediate products, actual production line). External information (EFSA reports, RASFF reports, EU and National guides, organizations bibliography, tools and databanks, validation for SMEs, emerging hazards). External communication (steps behind and forward in the food chain, good source of experience in the field). Mechanism of adverse effects (source/origin/nature of hazard).

Hazard analysis Likelihood of occurrence of hazards, taking into consideration prerequisite programmes, in the absence of additional control; likelihood and severity of adverse health effects associated with the hazards in the food in the absence of control; identified acceptable levels of the hazards in the food e.g. based on regulation, intended use, and scientific information; the nature of the facility and the equipment used in making the food product; the intended use and/or probability of product mishandling by potential consumers that could render the food unsafe.

Before applying decision tree start with hazard analysis (Codex)

Qualitative risk evaluation Description output (3x3) High Moderate risk Important risk Important risk PROBABILITY Real Small risk Moderate risk Important risk Small Small risk Small risk Moderate risk Limited Moderate Serious SEVERITY Risk analysis generates different levels of concern for FBOs

Semi-quantitative risk evaluation Score output (4x4) High 4 4 5 6 7 Real 3 3 4 5 6 Small 2 2 3 4 5 PROBABILITY Very small 1 1 2 3 4 1 2 3 4 Limited Moderate Serious Very serious EFFECT

Semi-quantitative method parameters Probability = the probability that the hazard is occurring in the end product, if the considered specific control measures are not present or are failing taking into consideration the next steps in the process, where an elimination or reduction to an acceptable level is possible and taking into consideration the already correctly implemented PRPs. Effect = the effect or the severity of the hazard related to human health.

Control measures Hazard Source/Reason Control measures E. Coli Presence in raw material Supplier specifications E. Coli Contamination from pests Pest control E. Coli Contamination from water Water management E. Coli Growth inappropriate cold storage Temperature management Control measures = those actions and activities that can be used to prevent hazards, eliminate them or reduce their impact or occurrence to acceptable levels. Control measures should be formalized (procedures, instructions, recordings).

Control measures They can be part of PRPs, OPRPs, CCPs. One measure can be appropriate for many hazards. More than one measures can be used for one hazard. The control measure must be validated (Codex: Guidelines for the Validation of Food Safety Control Measures CXG 69-2008). Validation of training?

Principle 2: Determining CCPs Critical Control Point (CCP): A step at which a control measure or control measures, essential to control a significant hazard, is/are applied in a HACCP system (Codex). The FBO should consider which, among the available control measures, should be applied at a CCP. The identification of a CCP requires a logical approach. Such an approach can be facilitated by the use of a decision tree or other methods, according to the knowledge and experience of the HACCP team.

Principle 2: Determining CCPs The identification of a CCP should consider the following: Next steps in the production process eliminating the hazards Another control measure for the hazard at another step At each step, the decision tree and/or other method should be applied to each hazard that may be reasonably expected to occur or be introduced and each control measure identified. Consider all flow diagram steps and PRPs to avoid unnecessary OPRPs and CCPs.

Principle 2 determining CCPs RISK LEVEL (R = P x E): SCALE 1 TO 7 4 5 6 7 High 4 3 4 5 6 Real 3 2 3 4 5 Small 2 PROBABILITY 1-2: no specific actions, control covered by PRPs 3-4: possible OPRP (operational PRP) (similar to CP) 5-6-7: CCP 1 2 3 4 Very small 1 1 2 3 4 Limited Moderate Serious Very serious EFFECT

OPRPs - CCPs CCPs = every batch/lot monitored, measurable critical limit OPRPs = regular monitor, criteria (measurable or not) CCP and OPRPs are usually product/process specific horizontal character of PRPs (e.g. allergen management, measures in high care areas, blanching). OPRPs stringency lies between PRPs and CCPs. OPRPs are not included in the Codex revision of the General Principles of Food Hygiene

CCPs in the field CCPs are established for high level of risk that is not controlled by PRPs or OPRPs. As result of identification of CCPs, the HACCP team: might be required to modify the process or the product (and include a control measure), if a particular identified hazard cannot be controlled at a specific step or before or at later stage; should establish and implement a monitoring system at each selected CCP.

CCPs in the field Number of CCPs can be zero. Nevertheless, scanning through risk evaluation and decision tree is kept and should be adequately justified and supporting desirable. PRPs are unnecessarily raised to CCPs. Elevation of PRPs and OPRPs to CCPs, is expected to be followed with very good CCP management. This is not always the case. PRPs are taken for granted and therefore neglected. Problems with ownership of HACCP plan. documentations is

3rdparty certification schemes Relevant schemes do not substitute official controls. Their hazard analysis and CCPs determination are put to the test as well (HACCP-based procedures). They provide a good aid in assessing HACCP implementation efficiency.

The ISO 22000 way Member States and EU representatives are members of the ISO organization. ISO Alimentarius. organization is member of the Codex OPRPs, food culture, management commitment

The ISO 22000 way Acceptable level of hazard in end product (when possible) 1stassessment: do we need control measures? 2ndassessment: Should they be OPRP or CCP? Feasibility of detection and correction of failure of control measures Pasteurization of raw milk (pasteurization recordings AND diverse valve)

OPRP or CCP? Low feasibility of detection or correction observation (oPRP) vs measurement (CCP)

1 more tree, then High safety risk from failure of control measure? Likehood of failure Effect of hazard Specifically designed step Subsequent steps Combination of measures Subsequent measures NO OPRP YES Feasible measurement + Timely detection and correction? NO OPRP Measurable Efficient monitoring Correct inhouse YES CCP

CONCLUSION A solid hazard analysis is the base of an effective HACCP system. Hazard analysis is demanding in resources and expertise. Fine balance of science and practice. Small FBOs face difficulties in conducting hazard analysis. Different methodologies can be applied to carry out Principles 1 and 2. Depending of the methodology used, categorisation of control measures can be different, but equally valid.

CONTACT Project e-mail: foodsafetyprojectTCc@gmail.com THANK YOU FOR YOUR ATTENTION Project funded by the European Union Aid Programme for the Turkish Cypriot community, implemented by NSF Euro Consultants Consortium