Improving Production Efficiency: Debrief and Changes for Rounds 1-3

The debrief and changes implemented over three rounds of production optimization, focusing on areas such as inspection processes, line balancing, communication, and meeting customer demand. Strategies like implementing Quality at the Source and Kanban systems were explored to enhance production efficiency.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

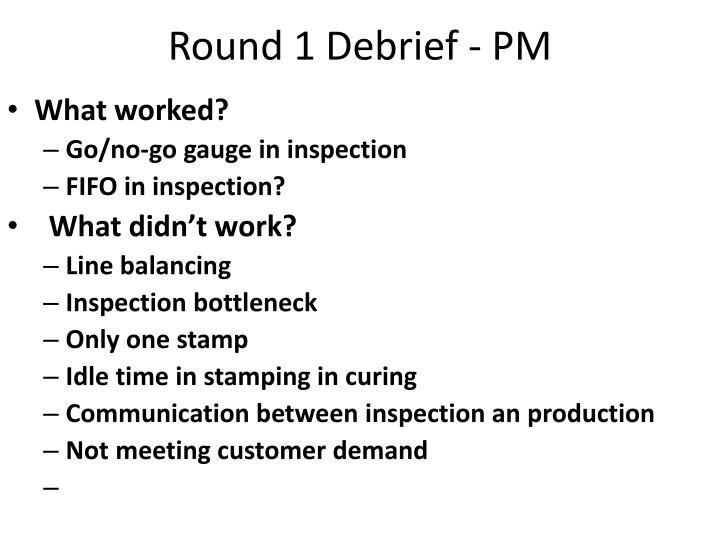

Round 1 Debrief - PM What worked? Go/no-go gauge in inspection FIFO in inspection? What didn t work? Line balancing Inspection bottleneck Only one stamp Idle time in stamping in curing Communication between inspection an production Not meeting customer demand

Changes for Round 2 Consider the following: Factory Layout Put tables in a line, eliminate WIP locations Eliminate bubba? Re-assign to real work! Other? Point of Use Storage (POUS) Batches? Store paper at folding Line Balancing How many folders do we need? 3? 4? Flexing work Split fold 2 into 2 operations Combine stamping and oven Training for stamping Poke-Yoke, Quality at the Source Sail height Stamp location (centering)

Round 2 Debrief - PM What worked? Quality at the source Less inventory Line balancing Better communication What didn t work? Batching

Changes for Round 3 Consider the following: Factory Layout Pull System, Kanban Pacemaker process? Shipping Kanban size? Continuous Flow and Supermarkets Poke-Yoke, Quality at the Source

Round 3 Debrief - PM What worked? What didn t work? Areas for improvement?