Improving Warehouse Crane Productivity with OWC Link

This project submission introduces a V2I VLC link design for VAT, enhancing warehouse crane accuracy and productivity using optical wireless communication. The solution enables precise positioning of living vehicles in smart city logistics systems. The document outlines the need for increased accuracy in warehouse operations, proposing a VLC/OWC communication link for Warehouse AGV solutions. The system utilizes lighting infrastructure and cameras to facilitate IoT/IoL connectivity between AGVs and cranes, optimizing loading and unloading processes.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

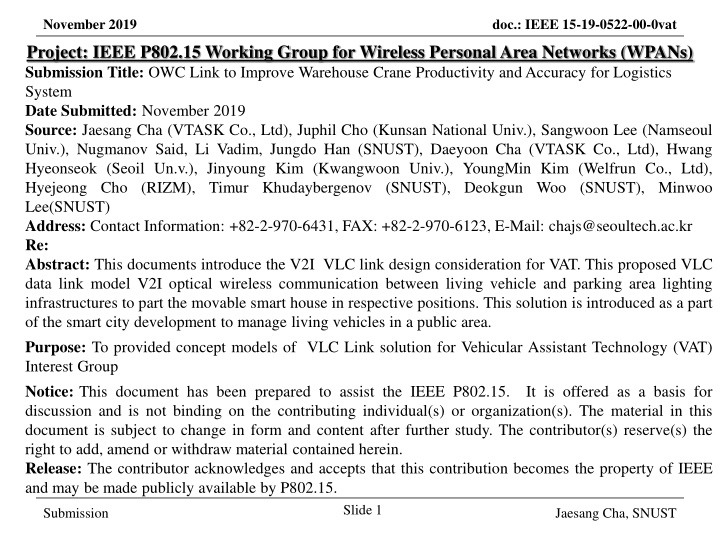

November 2019 Project: IEEE P802.15 Working Group for Wireless Personal Area Networks (WPANs) Submission Title: OWC Link to Improve Warehouse Crane Productivity and Accuracy for Logistics System Date Submitted: November 2019 Source: Jaesang Cha (VTASK Co., Ltd), Juphil Cho (Kunsan National Univ.), Sangwoon Lee (Namseoul Univ.), Nugmanov Said, Li Vadim, Jungdo Han (SNUST), Daeyoon Cha (VTASK Co., Ltd), Hwang Hyeonseok (Seoil Un.v.), Jinyoung Kim (Kwangwoon Univ.), YoungMin Kim (Welfrun Co., Ltd), Hyejeong Cho (RIZM), Timur Khudaybergenov (SNUST), Deokgun Woo (SNUST), Minwoo Lee(SNUST) Address: Contact Information: +82-2-970-6431, FAX: +82-2-970-6123, E-Mail: chajs@seoultech.ac.kr Re: Abstract: This documents introduce the V2I VLC link design consideration for VAT. This proposed VLC data link model V2I optical wireless communication between living vehicle and parking area lighting infrastructures to part the movable smart house in respective positions. This solution is introduced as a part of the smart city development to manage living vehicles in a public area. Purpose: To provided concept models of VLC Link solution for Vehicular Assistant Technology (VAT) Interest Group Notice: This document has been prepared to assist the IEEE P802.15. It is offered as a basis for discussion and is not binding on the contributing individual(s) or organization(s). The material in this document is subject to change in form and content after further study. The contributor(s) reserve(s) the right to add, amend or withdraw material contained herein. Release: The contributor acknowledges and accepts that this contribution becomes the property of IEEE and may be made publicly available by P802.15. Slide 1 doc.: IEEE 15-19-0522-00-0vat Submission Jaesang Cha, SNUST

November 2019 doc.: IEEE 15-19-0522-00-0vat Contents Needs for Increasing the accuracy and productivity of Warehouse Crane OWC Link to Improve Warehouse Crane Productivity Conclusion Slide 2 Submission Jaesang Cha, SNUST

November 2019 doc.: IEEE 15-19-0522-00-0vat Increase the accuracy and productivity of Warehouse Crane Needs Automated port warehouses are safer than conventional ones. The number of human-related disruptions falls, and performance becomes more predictable. Cargo ships maybe unloaded by several cranes, for increasing productivity AGV should determine which crane unloads which container Basic concept For loading or unloading freighter ship the crane is used. For big ships for increasing the speed of loading/unloading several cranes are used. AGVs which are transporting the container share with crane the information about container, so AGV/Crane knows where to load or deliver the container. Uses the lighting Infrastructure and Camera Installed on the crane, AGV or warehouse infrastructures to enable IoT/IoL Connectivity link between AGVs Google < Crane and AGV carrier > Slide 3 Submission Jaesang Cha, SNUST

November 2019 OWC Link to Improve Warehouse Crane Productivity and Accuracy doc.: IEEE 15-19-0522-00-0vat VLC/OWC communication link for Warehouse AGV solution Tx : Lighting of AGV or 2D Color Coded Package Distribution LED Labels Rx : CMOS Camera or PD Installed in the AGV Day-Night Communication Mode Modulations Color Code, QR-Code, VTASC, OOK, Offset-VPWM, Multilevel PPM, Inverted PPM, Subcarrier PPM, DSSS SIK etc. < OWC Link between Warehouse Crane to increase the accuracy and productivity> Data Rate : 1K ~ 5Mb/s Supported LoS (Line of Sight) AGV for transportation goods in the warehouse uses Available Distance : 5m ~ 200m decoded information with connected cloud server via IoT/IoL Technology. Use the Lighting or LED Labels to transmit information about type of goods, weight and etc. Slide 4 Submission Jaesang Cha, SNUST

November 2019 doc.: IEEE 15-19-0522-00-0vat Conclusion Proposed the OWC Link for Warehouse Crane to increase the accuracy and productivity Solution for Smart Warehouse. Uses the Lighting and Camera System installed in the Warehouse crane In this proposed goods transportation automation, LED lightning, CMOS Camera/PD installed in the warehouse crane and crane as a transceiver to share the transported container information. Slide 5 Submission Jaesang Cha, SNUST