Industrial Uses of Synthetic Polymers in Organic Chemistry

Explore the properties and applications of synthetic polymers in organic chemistry. Learn about the structure of nylon-66 and how vulcanization improves natural rubber. Discover the manufacturing process and uses of phenol-formaldehyde resins like Bakelite in various industries. Gain insights into the importance of polysulphide bridges in polymer chains for enhancing elasticity and strength.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

B.Sc III YEAR (6thSEM) ORGANIC CHEMISTRY TOPIC: Synthetic Polymers IB PG COLLEGE ,PANIPAT Era Garg Asst. professor (Chemistry)

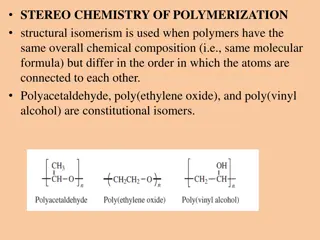

Q1.Nylon stocking gets a hole with a drop of HCl,Explain. Ans- elastic hosiery Structure of nylon-66 used in making

Q2.How rubber is vulcanized? How does it improves the properties of natural rubber? Ans- Natural rubber is soft and tacky ,becomes brittle at low temperatures. It temperature range is 285-335 k. Its elasticity is maintained.

When raw rubber is heated with Sulphur at 373-415 k it is vulcanized slowly. To accelerate the rate , some additives like 2-mercoptobenzothiazole is used.

Vulcanised rubber has excellent elasticity low water absorption tendency,resistance to action of organic solvents and oxidizing agents,hardness and stronger than tacky rubber. Hardness depends upon the amount of Sulphur added 5% for making tyre rubber.

Polysulphide bridges between polymer chains do not allow the chains to slip past each other when stretching force applied.

Q3.What are phenol-formaldehyde resins? Explain manufacture and industrial uses of Bakelite. Ans-

When phenol is treated with formaldehyde in the presence of acid or base catalyst, it undergoes condensation polymerization

USES: USES: 1. It is a thermosetting polymer , scratch and water resistant used for the manufacture of combs , fountain pens barrel , gramophone records.

2. Excellent electrical insulating properties,used in making switches, plugs etc. electrical goods. 3. Sulphonated bakelites used as ion exchange resins.

Thanks Thanks