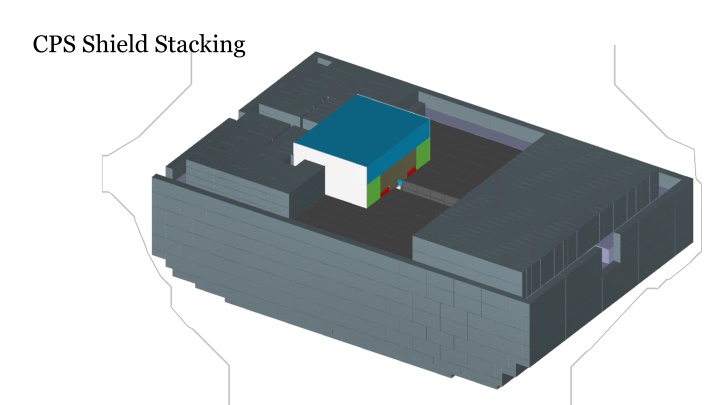

Innovative CPS Shield Stacking Techniques for Magnetic Systems

Explore the groundbreaking CPS Shield Stacking methods for optimizing magnetic system performance. Discover how top plates, beam holes, and magnet pole adjustments enhance shielding effectiveness and accommodate necessary components.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

CPS Shield Stacking Top plate added to magnet to bring the top of the magnet flush with the existing shielding.

Magnet Upstream end space: Free space behind the magnet to allow for electronics and cooling pipes. Support structure? Diameter of LCW feed? Electrical cables for magnet coils.

CPS downstream beam hole Downstream end of the shield has extra lead shielding removed to provide an expanding aperture. Beam hole has 4in X 4in square void through the shielding to the downstream face of the magnet. One tungsten brick is removed both above and below the downstream face of the magnet to accommodate the bend in the cooling pipes. Support structure around beam hole.

CPS Magnet Pole Make an adjustment to the angle of the contact surface to the Cu Core to increase material