Innovative Maple Syrup Production Using Waste Cooking Oil for Heating

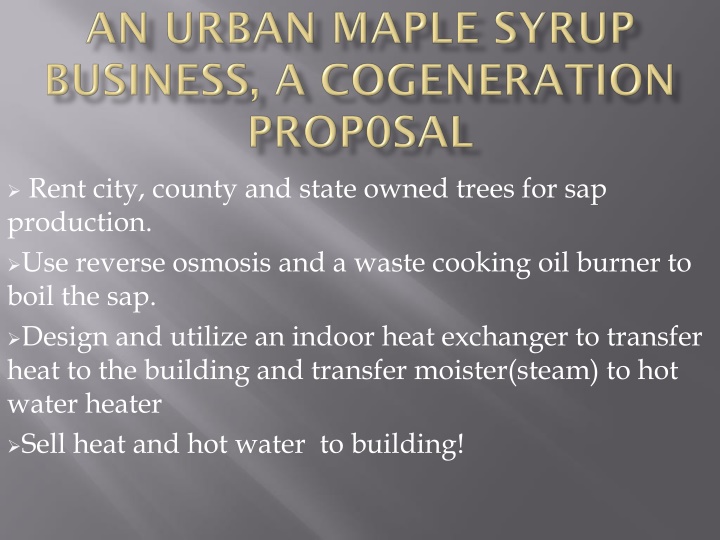

Utilize city-owned trees for sap production, implementing reverse osmosis and waste cooking oil burner for boiling. Design indoor heat exchanger to transfer heat efficiently, benefiting buildings. Explore cogeneration of maple syrup, hot water, and heat using waste oil. Generate urban employment and income, transforming maple trees into valuable resources.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Rent city, county and state owned trees for sap production. Use reverse osmosis and a waste cooking oil burner to boil the sap. Design and utilize an indoor heat exchanger to transfer heat to the building and transfer moister(steam) to hot water heater Sell heat and hot water to building!

Terrestrial and Cislunar exploration technologies, a veteran owned concern DUNS # 967877254 Steven Rappolee 810-334-4374 3501 North River RD, Apt 204H Ft Gratiot, MI 48059 2/23/2025 (C) Rappolee 2009/2011 2

The city of Port Huron will make available street and park maple species for sap harvesting. The city of Port Huron shall make available park land for a maple trees. The city of port Huron shall plant maples in a botanical experiment station The college shall make available in the student center space for a waste cooking oil heater to boil maple sap and space for a heat exchanger to process heat for the student center. The college will buy this heat. The college will buy the heated water

The company shall buy waste cooking oil through out port Huron and bring it to the student center to burn as fuel. During the rest of the winter the waste oil burner shall heat water and air after the sap run has stopped. Maple syrup cogeneration burns waste cooking oil to produce maple syrup, hot water and heat. It produces urban employment and income to city property owners and the city itself.

1 GALLON MAPLE SYRUP 1 gallon X 280 ounces = 280 ounces; 2 taps for every maple tree at 25 ounces of maple syrup per tap(50 per tree) yields the need for 6 trees. 1 GALLON MAPLE SYRUP 1 gallon X 40 gallons sap =39 gallons water X 7 = 273 gallons steam over a three week sap season;273 /21 days = 13 gallons steam.13/24 hours =0.51 gallons steam. Half a gallon of steam is not enough to heat even a portion of the student union, so clearly we need to burn much more waste oil to heat the building

TWO TAPS ONE TAP 500 maple trees produce 50 ounces of maple syrup each; or 25, 000 ounces. Divide by 280 ounces and this yields 89 gallons of maple syrup. 89 gallons X 40 gallons sap =3,571 gallons water X 7 =25,000 gallons steam/21 days = 1,190 gallons per day steam/24 hours =50 gallons steam per hour*** 89 gallons / 21 days 500 trees produce 25 oz of syrup or 12,500 ounces / 230 oz = 54 gallons of syrup

10 GALLONS MAPLE SYRUP 5 GALLONS MAPLE SYRUP 5 gallon X 40 gallons sap =195 gallons water X 7 = 1,365gallons steam over a three week sap season;1,365/21 days = 65 gallons steam.65/24 hours =2.70 gallons steam per hour. 5 gallons of syrup X 280 ounces =1,400 ounces/50 ounces from 2 taps per tree yields the need for 28 trees 10 gallons X 40 gallons sap = 400 gallons water X 7 =2,800 gallons(lbs?) steam / 21 days 133 gallons steam/24 hours =5.55 gallons per hour steam 10 gallons of maple syrup X 280 ounces =2,800 ounces / 50 ounces per taped tree =56 trees

WASTE COOKING OIL AS FUEL IS LOCAL FUEL Energy is used to process and transport both yellow grease and to manufacture biodiesel, we avoid both. We are buying a locally sourced fuel to produce a locally produced product . We are heating a local college building with food production process heat!*** ENERGY EQUIVALENTS AND COSTS OF WASTE OIL 60 Lbs of yellow grease will give you 1 million BTU = 1000 Lbs steam. There is 8 pounds of yellow grease in a gallon of yellow grease; 60 lbs/8 = 7.50 gallons 2007 price for yellow grease; $ 0.1875 Lb so X 8 = $1.50 per gallon(134,800BTU/gallon). We believe the cost of (local)waste cooking oil is below this

ONE ,ONE THOUSAND GALLON WASTE OIL VAT PER MONTH 500 MAPLE TREES PER COMMUNITY In the western and northern Michigan with an established rural maple syrup industry should make it possible to far exceed 500 trees and just one main building Michigan has a total of 20 million tapable sugar maple trees on local government lands; at 25 ounces per tap this would be 500 million ounces or 6,400 gallons How many gallons of waste cooking oil would it take to boil off even half the number below in notes 128,000 gallons of water boiled to steam would heat many a building

INVENTORY CITY MAPLE TREES ASSAY SUGAR CONTENT OF MAPLE TREES Count number of city owned trees in parks and streets. Count number of county owned tress Count maple trees on private property. Inventory trees with other willing townships. Inventory existing maple sap producers** Write grants to accomplish these tasks Assay sugar content of inventoried maple trees. Assay energy content of waste oil and heat BTU transfer to building air and hot water Develop software to transfer BTU to a billing system

GRANT WRITING GRANT WRITING Diesel powered waste cooking oil tanker truck makes rounds on a route. Diesel powered maple sap tanker truck makes rounds of city streets collecting collected sap. Off road vehicles collect maple sap from off road sap collecting in parks, cemeteries and private property One diesel powered waste cooking oil tanker truck. One diesel powered maple sap collecting vehicle Two off road diesel powered vehicles with 1000 gallon food grade tanker. These vehicles are ADA compliant for the disabled farmer/driver; pumps and lifting devices collect sap from sap collecting bins at the trees

BTU/gallon water conversion to Lbs steam. How many gallons/Lbs in a restaurant waste oil vat? Waste heat from steam recovery; conversion to building heat Number of assayed tress in Port Huron and distance to the college Methods of transportation ? A small food grade tanker truck with a diesel engine picks up sap on a route; a second small tanker truck picks up waste restaurant oil

32 X 24 hours = 770 gallon/day X 7 days = 5390 gallons a week. 23,000 gallons per month; this might be 30 to 40 restaurants per month worth of used cooking oil If all of the BTU s to heat the student center first produced maple syrup, then this represents about 10 gallons **an hour or 420 gallons of steam! St Clair Community college Student center; 77,000 square feet. 50 BTU/hour per square foot to heat building X 77,000 =3,850,000 BTU/hour. 17,000 BTU per Lb yellow grease X 7Lb s per gallon = 120,000 BTU. 32 gallons of waste oil per hour

1 gallon per hour for 2 weeks, 24 gallons per day,336 gallons in 2 weeks. 1 gallon of syrup takes 400,000 BTU s to make so recovering the heat from the steam would produce about 10% of the student centers heat per gallon of maple syrup produced. 6 gallons per hour of waste cooking oil to produce 1 gallon of syrup 1 gallon of syrup every hour needs 11 trees, 264 trees for 24 hours; 3,696 trees for 2 weeks.

A MASONRY HEATER/FORCED AIR MAPLE SYRUP ARCH VALUE ADDED URBAN FOOD PROCESSING A wood fired arch is partitioned between two rooms; one room is a public gathering place** and contains the masonry oven stone fa ade and wood storage places. Also is a air tight door with a Plexiglas viewing window, some radiant heat will accrue to the public space Burning a locally produced fuel source to produce both maple syrup and building hot water and heat, the wood and waste cooking oil is local and minimally processed. Local wood and waste oil does not consume as much energy to transport

HOW MUCH DOES THE COLLEGE PAY TO HEAT THE STUDENT CENTER? We would be compensated for any reductions in student center heating costs and hot water heating fuel reductions while the system is in operations On the other side of the wall and masonry heater fa ade is the arch and boiling pan for the maple sap. On top of this is a steam tubing/outside air heat exchanger that distills the steam and extracts heat for the building air system and can produce hot water

THE STUDENT UNION IS 77,OOO SQUARE FEET. IT TAKES 50 BTU/HOUR PER SQUARE FEET TO HEAT How many BTU/hour to heat the student union? BTU/hour = 50 BTU over I square feet X 77,000 square feet over 1 = 4,235,000. It takes 400,000 BTU to remove 42 gallons of water from 1 gallon of maple syrup, how many gallons of maple syrup an hour would we need to produce to heat the student union building? The answer is 10 1/2 gallons. How many gallons of waste cooking oil to produce 10 gallons of syrup? Waste oil at 130,000 btu per gallon would result to 35 gallons per hour. If however we have 10 maple sap boilers each producing 1 gallon maple syrup per hour for two weeks . Value added? Maple syrup $40 per gallon , 400,000 BTU sold to the student center?

IN THE FALL THE MAPLE SAP HEATERS COULD PROCESS SORGHUM MOLASSES

10,000 TREES ALONG THE INTERSTATES 10,000 TREES ALONG THE STATE AND CITY ROADS 10,000 trees X 23 oz of syrup per tap = 230 oz at 230 oz per gallon of maple syrup. This comes to 1000 gallons of maple syrup, 1000 x 400,000 BTU =400,000,000 /3,850,000 per hour to heat the student center; 104 hours

HEAT RECOVERY FROM STEAM TO HEAT BUILDING But a enclosed system that does not allow for contamination from the out side air should render the distilled water from the maple sap sterile. This creates possibilities; boiling hard cider from local apples should produce a Calvados , could we stager a sorghum molasses season with a hard cider season for energy cogeneration? USE STEAM TO DISTILL LIQUOR Hard cider is heavily filtered; it should behave well in a sealed maple sap boiler. Much lower heat is used in the arch as we want to volatize just the alcohol.