Innovative Techniques for Glue Management in Device Assembly

In this project update, advancements in managing glue viscosity, tooling design progress, heater loading tools, cell handling techniques, and alignment procedures are discussed. The implementation of systematic warm-up for glue, optimization trials for glass deposition, and preparations for heater assembly are detailed. Expectations for improved glue handling and readiness for assembly by the end of January are highlighted.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

HEATERS LOADING @CPPM Eric Vigeolas 17/12/2018

Stycast 2850FT Following the observation we made that the glue tend to dry out and get more viscous in a 1kg Pot. We decided to split, at the opening, the glue in several little cartridges Worth after one month non of the pot are usable Viscosity change will make this glue usage quite difficult during detector assembly We will try a systematic warm up of the glue (50 C) 1 h before mixing to increase repeatability

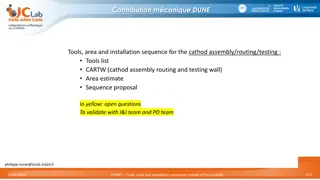

Tooling design progress 3 axis deposition tool is ready We started the first deposition trials January we will run glass deposition test to control repeatability and optimize pattern and surface coverage We will perform minimal thickness measurement vs load

Heater loading tool Design almost done, just need to complete the bridge design Load cell has been added + micro screw for vertical adjustment

Heater placement Specific alignment references has been added to align the heater before cell mounting and heater loading Alignment blocs Heater footprint

Cell handling Cell will be vacuumed on the TPG surface, gap will be added on the cooling bloc to create a kinematic assembly Cell alignment is done with the cooling bloc pins TPG vacuum grove Grove to prevent from glue excess Gap for kinematic assembly

Cell Alignment A kinematic assembly has been designed for the cell alignment

Conclusion We expect a better management of the glue with the warming step which will be added prior to the deposition By January we will focus on glue deposition optimization and repeatability tests on glass tiles By end of January we will be ready for heaters assembly