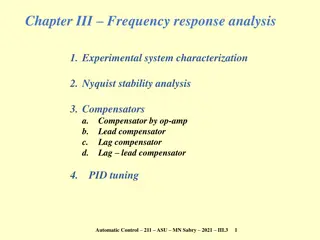

Introduction to Automatic Control in Processes

Automatic control plays a crucial role in maintaining process variables close to their setpoints without manual intervention. This control method ensures higher quality, improved safety, increased efficiency, and environmental protection in various industrial processes. Learn about common variables controlled, benefits of automatic control, feedback control principles, and practical examples of maintaining desired temperatures in this insightful course.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Course PEF3006 Process Control Fall 2017 Introduction to process control By Finn Aakre Haugen (finn.haugen@usn.no) PEF3006 Process Control. USN. F. Haugen. 2017 1

Software requirement for running SimView simulators Most of the lectures and exercises of this course include running simulators. These simulators have been developed in LabVIEW. Here are the requirements for the simulators to run. PEF3006 Process Control. USN. F. Haugen. 2017 2

What is automatic control? PEF3006 Process Control. USN. F. Haugen. 2017 3

Automatic control is making process variables stay sufficiently near their setpoints (references) - automatically (i.e. without manual operations): Without control or with poor control With good control Specifications about control error not satisfied! Less error! (Smaller variance) Max limit Min limit Setpoint, ySP Control error, e = ySP - y Process output, y t t PEF3006 Process Control. USN. F. Haugen. 2017 4

Common process variables to be controlled to follow setpoints: Temperature (heat exchanger, reactor, room) Pressure (reactor, oil/water/gas-separator) Flow (gas or liquid flows in pipe) Level (tank) Position (ship, robot) Rotational speed (motor) PEF3006 Process Control. USN. F. Haugen. 2017 5

Areas where automatic control can make large benefits: Product quality Product economy Safety Environment protection Comfort Feasibility Automation PEF3006 Process Control. USN. F. Haugen. 2017 6

The principle of feedback control PEF3006 Process Control. USN. F. Haugen. 2017 7

Think about how you you act while you are controlling the temperature of the water in the shower to make the temperature become equal to the desired temperature (aka. the temperature setpoint or reference), even under disturbances like reduced availability of hot water and variations of air temperature in the room. PEF3006 Process Control. USN. F. Haugen. 2017 8

I guess you act like this (text on next slide): Room temperature = process disturbance or environmental variable Shower = process Control loop. Feedback Brain = controller incl. temp.- setpoint (brain) Water temperature = process variable Hand = sensor Hand and valve (tap) = Actuator PEF3006 Process Control. USN. F. Haugen. 2017 9

You manipulate the actuator (tap) until the difference between the temperature setpoint and the temperature measurement is sufficiently small. This is error-driven control! It is the fundamental control principle in technical, industrial, biological, social system. More common terminology than error-driven control: Feedback control Closed loop control Automatic control PEF3006 Process Control. USN. F. Haugen. 2017 10

Temperature control system implemented with industrial components: Aktuator Sensor Regulator PEF3006 Process Control. USN. F. Haugen. 2017 11

Piping & Instrumentation Diagram (P&ID) for the temperature control system: Room temperature = process disturbance or environmental variable Temperature setpoint Measurement signal Control signal Water temperature = process variable TC TT Actuator Controller Sensor (TT = Temperature Transmitter) (TC = Temperature Controller) PEF3006 Process Control. USN. F. Haugen. 2017 12

So, how does the controller act? It manipulates the process variable by changing the control signal to the actuator until the control error has become zero. So, it continually improves, until the aim is reached: Zero error. In practice it is the mean error which will be zero as there will always be some disturbances making the error vary somewhat, see the figure below. Process variable Setpoint Control error = Setpoint - Process variable PEF3006 Process Control. USN. F. Haugen. 2017 t 13

Example of industrial feedback control system: Level control of wood chip tank (Process & Instrumentation Diagram - P&ID) Conveyor belt Feed screw Actuator win [kg/min] ws[kg/min] Chip tank Process variable Control signal Controller Level sensor h [m] u LC LT Wood chip Setpoint hSP [m] 0 m Outflow to subsequent process units wout [kg/min] Process disturbance PEF3006 Process Control. USN. F. Haugen. 2017 14

Simulation! PEF3006 Process Control. USN. F. Haugen. 2017 15

Simulation: Level control of wood-chip tank (Run the exe-file in the link.) PEF3006 Process Control. USN. F. Haugen. 2017 16

Another example: PEF3006 Process Control. USN. F. Haugen. 2017 17

Simulator: Temperature control of liquid tank PEF3006 Process Control. USN. F. Haugen. 2017 18

A third industrial example: Dynamic positioning (DP) of ships Eng.: Disturbance Forstyrrelse Forstyrrelse Eng.: Disturbance Forstyrrelse Posisjons- sensor(er) Tilbake- kopling Posisjons- regulator Posisjons- referanse(r) PEF3006 Process Control. USN. F. Haugen. 2017 19 Kongsberg Maritime AS

Simulator PEF3006 Process Control. USN. F. Haugen. 2017 20

Symbols in Piping & Instrumentation Diagrams (P&IDs) PEF3006 Process Control. USN. F. Haugen. 2017 21

Standards for P&IDs: ISO 3511-1 ISA S5.1 PEF3006 Process Control. USN. F. Haugen. 2017 22

Letter codes (for P&IDs): PEF3006 Process Control. USN. F. Haugen. 2017 23

Instrumentation symbols: Instrument mounted in the field (at the measurement point) FC 1 Instrument mounted in a central place available for the operator, e.g. in a control room FC 1 PEF3006 Process Control. USN. F. Haugen. 2017 24

Process fluid and signals: Process fluid (liquid or gas) General (undefined) signal Pneumatic signal Electrical signal PEF3006 Process Control. USN. F. Haugen. 2017 25

Valves: Valve with membrane actuator (Is also used as a general symbol for control valves.) Valve with electrical motor Magnetic valve (On/Off) Hand (manually) operated valve Valve with fixed opening PEF3006 Process Control. USN. F. Haugen. 2017 26

Tanks: Absorption/stripping column Open tank Distillation column Closed tank Stirring motor Reactor Autoclave Jacket for heating or cooling PEF3006 Process Control. USN. F. Haugen. 2017 27

Heat exchanger: Process fluid CW Heat exchanger (CW = Cold Water HW = Hot Water) PEF3006 Process Control. USN. F. Haugen. 2017 28

Pumps: General pump symbol P-1 Centrifugal pump Displacement (dosing) pump Compressor Turbine PEF3006 Process Control. USN. F. Haugen. 2017 29

Block diagrams of control systems PEF3006 Process Control. USN. F. Haugen. 2017 30

A simplified block diagram showing the most essential parts: We will relate this block diagram to the level control system of the wood-chip tank. Process disturbance (environmental variable) Process variable or process output Control error d Setpoint or reference Control signal e y u ySP Controller (function) Actuator Process E.g. [m] or [%] or [mA] E.g. E.g. [m] [kg/min] or [%] or [mA] Feedback control loop ym Sensor Feedback Process measure- ment E.g.[m] or [%] or [mA] PEF3006 Process Control. USN. F. Haugen. 2017 31