Investigation and Simulation of Dust Particle Transmission

This project focuses on studying and simulating the flow of dust particles to control potential hazards in manufacturing processes. It aims to investigate the generation, transmission, and dispersion of dust particles, proposing solutions for containment.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

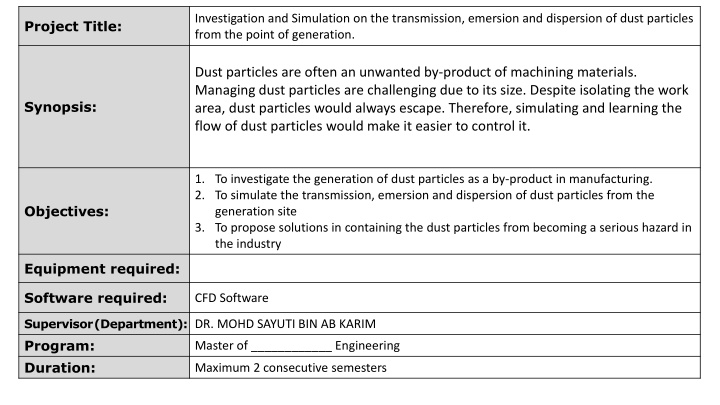

Investigation and Simulation on the transmission, emersion and dispersion of dust particles from the point of generation. Project Title: Dust particles are often an unwanted by-product of machining materials. Managing dust particles are challenging due to its size. Despite isolating the work area, dust particles would always escape. Therefore, simulating and learning the flow of dust particles would make it easier to control it. Synopsis: 1. To investigate the generation of dust particles as a by-product in manufacturing. 2. To simulate the transmission, emersion and dispersion of dust particles from the generation site 3. To propose solutions in containing the dust particles from becoming a serious hazard in the industry Objectives: Equipment required: Software required: CFD Software Supervisor(Department): DR. MOHD SAYUTI BIN AB KARIM Program: Master of ____________ Engineering Duration: Maximum 2 consecutive semesters

Investigation on the occupational injury and diseases that occur despite following OSHA Standards. Project Title: Occupational injury and diseases are constantly showing up in our country despite the strict occupational health and safety standards. This clearly shows that there is a flaw in the system. Therefore, finding out the cause would help in solving this problem. Synopsis: 1. To investigate the recent occupational injury and diseases cases and their causes 2. To evaluate the relationship between the causes and the OSHA Standards and figuring out the flaw 3. To find remedies to solve the flaw and decrease the number of cases. Objectives: Equipment required: Software required: Supervisor(Department): DR. MOHD SAYUTI BIN AB KARIM Program: Master of ____________ Engineering Duration: Maximum 2 consecutive semesters

Investigation on the trend of occupational injuries and diseases based on the type of industry, the economic growth and safety regulations. Project Title: The occupational injury and diseases data have not been properly studied and related to the environmental factors to find out its relations. If the relationship between these variables has been found, future prediction and problem solving would be easy. Therefore, the current occupational injury and diseases has to be studied. Synopsis: 1. To determine the recent occupational injury and diseases data based on their respective industries 2. To investigate the relationship between the data observed with the environmental factors involved such as the economic growth and the safety regulations 3. To predict the future data and the find the solution by using the relationship found. Objectives: Equipment required: Software required: Supervisor(Department): DR. MOHD SAYUTI BIN AB KARIM Program: Master of ____________ Engineering Duration: Maximum 2 consecutive semesters

Classification of high voltage cable joint defects using support vector machine and noise reduction on partial discharge signals Project Title: In this work, classification of high voltage cable joint defect types using support vector machine and noise reduction techniques on partial discharge signals will be performed. Four cross-linked polyethylene (XLPE) cable joints with artificially created defects will be prepared based on the defects commonly encountered on site. Different noise reduction techniques will be applied to denoise the PD signals. The denoised signals will be used as a feature for classification of defects in cable joints using support vector machine. The classification results will be compared between the proposed method and the existing works to evaluate the performance of the applied techniques. 1. To perform measurement of partial discharge (PD) on artificially-prepared cable joint defects 2. To apply support vector machine and various noise reduction methods on PD signals for classification of XLPE cable joint defects 3. To compare the classification results between the proposed method and the existing works Synopsis: Objectives: Equipment required: Software required: Partial discharge measurement setup, high voltage generation kit, cable joint MATLAB, partial discharge analysis software Supervisor(Department): Assoc. Prof. Ir. Dr. Hazlee Azil Illias (Electrical) Program: Master of Power System Engineering / Master of Engineering (Power System) Duration: Maximum 2 consecutive semesters