IT Applications in Supply Chain Management

Information Technology plays a crucial role in Supply Chain Management through advanced planning, scheduling, electronic business, and knowledge utilization. Performance measurement, benchmarking, green and global supply chains, coordination, sourcing, contracts, and inventory planning are key aspects discussed. The significance of IT tools for project management, manufacturing, and decision support systems like MIS and DSS is highlighted, along with the role of ERP and CRM systems. Various concepts are explained with practical examples and references.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

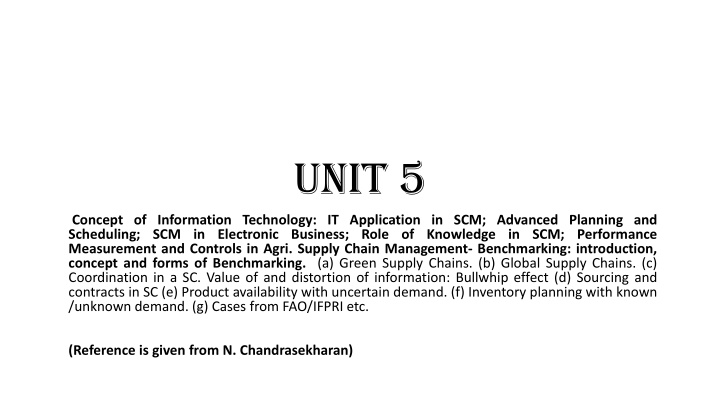

UNIT 5 Concept of Information Technology: IT Application in SCM; Advanced Planning and Scheduling; SCM in Electronic Business; Role of Knowledge in SCM; Performance Measurement and Controls in Agri. Supply Chain Management- Benchmarking: introduction, concept and forms of Benchmarking. (a) Green Supply Chains. (b) Global Supply Chains. (c) Coordination in a SC. Value of and distortion of information: Bullwhip effect (d) Sourcing and contracts in SC (e) Product availability with uncertain demand. (f) Inventory planning with known /unknown demand. (g) Cases from FAO/IFPRI etc. (Reference is given from N. Chandrasekharan)

Role of IT Internal and external changes For e.g. customer order fulfillment and progressive status Systematized and synchronized with traceability

Concept of IT IT can be referred to as the study, design, development, implementation, support or management of computer based information systems, particularly software applications and computer hardware. It is the combination of telecommunications and computing to obtain, process, store, transmit and output information in the form of voice, pictures, words and numbers Variety of disciplines including telecommunications, I S, Software development, multimedia publishing, DBMS, graphical and visual applications and computer modelling.

Need for IT Data transfer Information retrieval Machine and process control

Top vendors of SCM solution providers SAP Oracle Sage Group Infor Global Epicor

IT tools for Business Project Management- features for scheduling, tracking, monitoring, reporting activities within multiproject environment. Computer Aided Design/ Manufacturing CIM- integrated use of computer aided techniques Manufacturing Execution system- consist of one or more modules used to track inventory and to insure and document the proper execution of manufacturing process. MIS- designed to provide management personnel with up to date information on an organisations performance/ business activities. Eg. Annual report for a stockholder

Cont. DSS- automated MIS, Two categories- Enterprise wide DSS and desktop DSS ES- based on AI , requires knowledge base, a fact base and a rule base. Knowledge Management- two ways- documenting individuals KB and disseminating through manuals or database. ERP-SAP, ORACLE FINANCIALS, BAAN (Baan was a vendor of enterprise resource planning (ERP) software that is now owned by Infor Global Solutions. CRM SCM, eSCM

IT applications in SCM MRP- reduce processing time, consistency, speed, accuracy MRP II- Manufacturing Resources Planning- MIS,DBMS, RDBMS (is a database management system which is based on the relational model as invented by E. F. Codd, of IBM's San Jose Research Laboratory. ERP- Integration platform by master tables E ERP- SCM- transaction execution, collaboration and coordination, Decision Support. Agritech startup WayCool Foods, IIT Madras join hands for climate-smart agricultural practices- Through this partnership, WayCool Foods would provide technical solutions for seeding and expansion of the Regenerative Agriculture Sustainable Architecture (RASA) tech stack Read more at: https://economictimes.indiatimes.com/tech/startups/agritech-startup-waycool-foods-iit-madras- join-hands-for-climate-smart-agricultural- practices/articleshow/100554175.cms?utm_source=contentofinterest&utm_medium=text&utm_ campaign=cppst

Role of internet in SCM Info availability and visibility Enabling single point of contract for data Allowing decisions based on Supply chain Info Enabling collaboration with supply chain partners issues- complexity Dependence on others Procurement and implementation

Advanced planning and scheduling APS- Synchronizes manufacturing operations and resources with customer priorities using the planning process constraints. Able to execute forecast In which plant should we run this production When should we promise the customer s order? Evolution of APS- over ERP

CFPR Collaborative forecasting planning and replenishment The CPFR model presents the aspects in which industries focus. The model provides a basic framework for the flow of information, goods, and services. In the retail industry the retailer typically fills the buyer role, a manufacturer fills the seller role, and the consumer is the end customer. The center of the model is represented as the consumer, followed by the middle ring of the retailer, and finally the outside ring being the manufacturer. Each ring of the model represents different functions within the CPFR model. The consumer drives demand for goods and services while the retailer is the provider of goods and services. The manufacturer supplies the retailer stores with product as demand for product is pulled through the supply chain by the end user, being the consumer. JDA Software

SCM in E Business E Commerce ( refer pg. no. 447, Supply chain process automation) E business ( refer Table 15.3, pg. no. 447, Application of e-Business tools ) Is e-commerce the same as e-business? While some use e-commerce and e-business interchangeably, they are distinct concepts. In e-commerce, information and communications technology (ICT) is used in inter- business or inter-organizational transactions (transactions between and among firms/organizations) and in business-to-consumer transactions (transactions between firms/organizations and individuals). In e-business, on the other hand, ICT is used to enhance one s business. It includes any process that a business organization (either a for-profit, governmental or non-profit entity) conducts over a computer-mediated network. A more comprehensive definition of e-business is: The transformation of an organization s processes to deliver additional customer value through the application of technologies, philosophies and computing paradigm of the new economy.

Some e commerce initiatives of Blue Dart Track Dart Mail Dart Location finder Transit time finder Billing Schedule a pickup Waybill generation Image Dart proof of delivery

Role of Knowledge Worker in SCM Someone who adds value by processing existing information to create new information which could be used to define and solve problem.

KW Managing Critical Factors Fuel costs build Build up of just in case inventories Interest rates Dynamic customers and import/export changes The cost of new security requirements Shipping delays, credits and other management

Benchmarking The continuous process of measuring products, services, and practices against the company s toughest competitors or those renowned as industry leaders Quantitative- cycle time is less than 25 hrs As-Is to To-Be modelling

Benchmarking can take the form of several different types: Internal benchmarking a comparison of internal operations such as one site (or project team) against another within the same company. Competitive benchmarking a comparison against a specific competitor for the product, service or function of interest. Generic benchmarking a comparison of business functions or processes that are the same, regardless of industry or country. Types of benchmarking

The Greening of Supply Chains - Producing, packaging, moving, storing, delivering and other supply chain activities can be harmful to the environment Supply chains will work harder to reduce environmental degradation Large majority of consumers influenced by a firm s environmental friendliness reputation Recycling and conservation are a growing alternative in response to high cost of natural resources Current Trends in Supply Chain Management (Cont.) 18

Current Trends in Supply Chain Management- Cont. Reducing Supply Chain Costs Cost reduction achieved through: Reduced purchasing costs Reducing waste Reducing excess inventory, and Reducing non-value added activities Continuous Improvement through Benchmarking-improve over competitors performance Trial & error Increased knowledge of supply chain processes 19

Case Study Wal-Mart s Green Supply Chain Management

Theme Inside out approach for green supply chain management

Some Supply Chain Practices Prequalification of suppliers Require or encourage environmental criteria for approved suppliers Require or encourage suppliers to undertake independent environmental certification Environmental requirements at the purchasing phase Build environmental criteria into supplier contract conditions Incorporate EHS staff on sourcing teams Supply base environmental performance management Supplier environmental questionnaires Supplier environmental audits and assessments

Supply Chain Practices Build environmental considerations into product design Jointly develop cleaner technology with suppliers Conduct life cycle analysis in cooperation with suppliers Engage suppliers in design for environment (DFE) product innovation Coordinate minimization of environmental impact in the extended supply chain Develop tools that assist in the DFE effort Cooperate with suppliers to deal with end-of-pipe environmental issues Reduce packaging waste at the customer/supplier interface Reuse/recycle materials in cooperation with the supplier Launch reuse initiatives (including buy backs and leasing) Reverse logistics Give supplier an incentive to reduce the customer s environmental load

Appendix A: List of Measurement Items for GSCM practices implementation source: Confirmation of a Measurement Model for Green Supply Chain Management Practices Implementation Supported by the Ninth Huo-yingdong Young Faculty Foundation 91082 , the National Natural Science Foundation of China Project (70202006), the Natural Science Foundation of Liaoning Province (2051020), and a research grant by The Hong Kong Polytechnic University (A630). Factors Internal environmental management (IEM) Measurement items 1.Commitment of GSCM from senior managers (IEM1) 2.Support for GSCM from mid-level managers (IEM2) 3.Cross-functional cooperation for environmental improvements (IEM3) 4.Total quality environmental management (IEM4) 5.Environmental compliance and auditing programs (IEM5) 6.ISO 14001 certification (IEM6) 7.Environmental Management Systems exist (IEM7) 8.Eco-labeling of Products (GP1) 9.Cooperation with suppliers for environmental objectives (GP2) 10.Environmental audit for suppliers internal management (GP3) 11.Suppliers ISO14000 certification (GP4) 12.Second-tier supplier environmentally friendly practice evaluation (GP5) 13.Cooperation with customers for eco-design (CC1) 14.Cooperation with customers for cleaner production (CC2) 15.Cooperation with customers for green packaging (CC3) 16.Design of products for reduced consumption of material/energy (ECO1) 17.Design of products for reuse, recycle, recovery of material, component parts (ECO2) 18.Design of products to avoid or reduce use of hazardous products and/or their manufacturing process (ECO3) 19.Investment recovery (sale) of excess inventories/materials (IR1) 20. of scrap and used materials (IR2) 21. of excess capital equipment (IR3) Green purchasing Cooperation with customers Eco-design Investment recovery A five-point scale: 1=not considering it, 2=planning to consider it, 3=considering it currently, 4=initiating implementation, 5= implementing successfully

Appendix B: List of Measurement Items for performance outcomes Factors Environmental performance (EP) Measurement items 1. reduction of air emission (EP1) 2. reduction of waste water (EP2) 3. reduction of solid wastes (EP3) 4. decrease of consumption for hazardous/ harmful/ toxic materials (EP4) 5. decrease of frequency for environmental accidents (EP5) 6. improvement of an enterprise s environmental situation (EP6) 1. decrease of cost for materials purchasing (ECP1) 2. decrease of cost for energy consumption (ECP2) 3. decrease of fee for waste treatment (ECP3) 4. decrease of fee for waste discharge (ECP4) 5. decrease of fine for environmental accidents (ECP5) 1. increase amount of goods delivered on time (OP1) 2. decrease inventory levels (OP2) 3. decrease scrap rate (OP3) 4. promote products quality (OP4) 5. increase product line (OP5) 6. improve capacity utilization (OP6) Economic performance (ECP) Operational performance (OP) A five point scale: 1=not at all, 2=a little bit, 3= to some degree, 4=relatively significant and 5=significant

Initiatives by Wal-Mart Green Logistics Campaign to convince suppliers A move toward sustainability CSR Sustainable vale networks Green website

What are Global Supply Chains Global Supply Chains (GSCs) are worldwide networks of suppliers, manufactures, warehouses, distribution centers and retailers through which raw materials are acquired, transformed and delivered to customers (OECD, Supply Chains and the OECD Guidelines for Multinational Enterprises, 2002)

Key enablers of Global Supply Chains Globalization, falling transportation and telecom costs, low tariffs, and technological improvements have changed global supply chains. Firms are increasingly: Outsourcing / offshoring some of their activities. Relying on alliances and joint ventures for global competitiveness. Using logistics to improve supply chain efficiency. Firms are increasingly part of global supply chains, mostly through trade and investment relationships with the foreign countries. In order to thrive, firms need: Smart Borders and world-class transportation infrastructure. Leading edge communication infrastructure. Free trade and investment. Smart Regulations.

A more detailed GSCs (Oil & gas supply chain ) Upstream supply chain Downstream supply chain Source: KPMG, 2009.

Definition The bullwhip effect can be explained as an occurrence detected by the supply chain where orders sent to the manufacturer and supplier create larger variance then the sales to the end customer. These irregular orders in the lower part of the supply chain develop to be more distinct higher up in the supply chain.

Reasons of Bullwhip Effect Over and under reaction to demand by the supply chain links Difference in perception by supply chain links Exaggerated demand and cancellation of orders by customers Accumulation of demand by the companies for order batching to suppliers. Price variations like discounts, sales promotion schemes, raise in prices, quantity discount etc. Relying on past information of demand to assess current demand.

Side-effects of Bullwhip Effect Profitability Decrease Customer service Rate Decrease Lead Time Increase Transportation cost Increase Inventory cost Increase Production cost Increase (Chopra et al.)