Laboratory Equipment Qualification in Pharmacy College

Learn about the qualification process for laboratory equipment at KLE College of Pharmacy in Belagavi. Discover the importance, reasons, and specific tests involved in ensuring equipment efficiency and compliance. Explore the calibration procedures for hardness testers and more.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

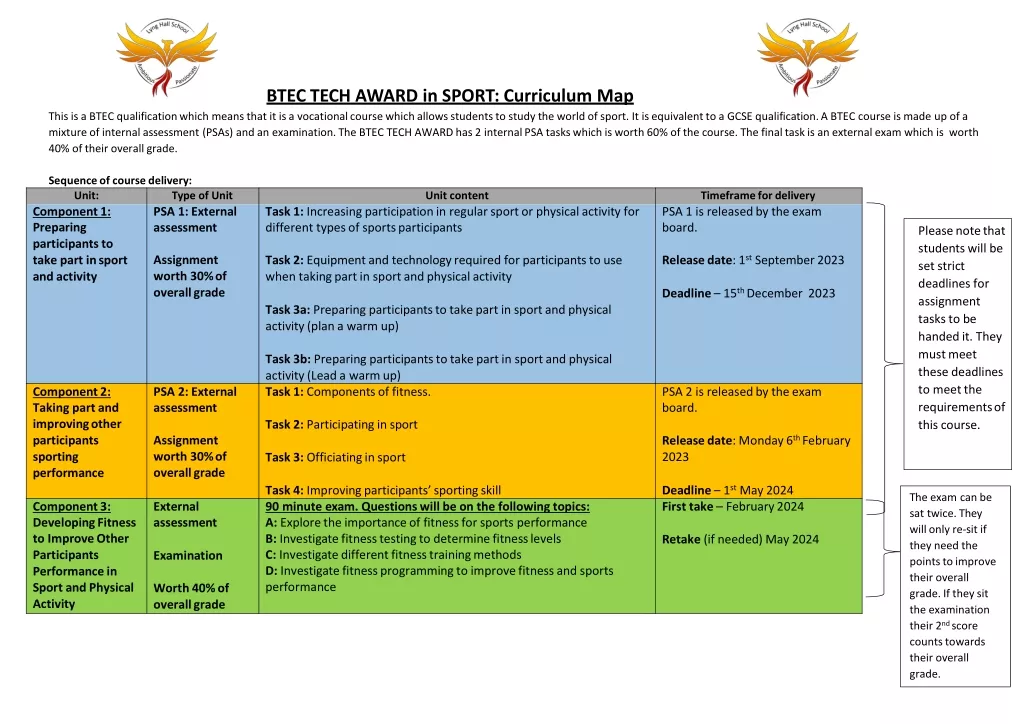

KLE College of Pharmacy, Belagavi A Constituent Unit of KLE Academy of Higher Education and Research Belagavi QUALIFICATION OF LABORATORY EQUIPMENTS

Contents: Introduction Qualification of Hardness tester Qualification of Friability test apparatus Qualification of Tap density tester Qualification of Disintegration Tester Qualification of Dissolution test apparatus

Qualification: Qualification is described as the action of proving and documenting that any premises, systems and items of equipment work correctly and actually leads to the expected results. Purpose To document the original installation conditions and establish that the equipment is suitable for the task it is assigned. The protocols must be organised, easy to follow and must "Test' each major component or operation. Testing during IQ and OQ stage is performed either on systems or on individual pieces of equipment. The best approach is to use the systems for the qualification program. Systems are the combination of individual units that must work together as one.

Reasons to Perform Qualification: Required by FDA or other regulatory agencies throughout the world. Qualification makes good business sense, and in long run it will save the company's money and time. Initial cost of qualification is huge, but if it is executed correctly it will save the cost during the life of the equipment and also will assure that the equipment is functioning as required. Qualification helps in tracking and thus fixing problems during operation

Hardness Tester Hardness (crushing strength) It is the load required to crush the tablet when placed on its edge. If the tablet is too hard, it may not disintegrate in the required period of time. And if the tablet is too soft, it will not withstand the handling during subsequent processing such as coating or packaging. Some of the devices used to test tablet hardness are: 1. Monsanto tester 2. Strong-cobb tester 3. Pfizer tester. 4. Erwika tester

Monsantotester Strong-cobb tester

Pfizer tester. Erwika tester

Qualification of Hardness Tester Standard Operating Procedure Department : Quality Control Department Title: Calibration of Hardness Tester Objective: To provide the procedure for calibration of hardness tester Scope: Applicable to determination of weight, diameter, hardness and thickness of a tablet during in process checking Responsibility: Quality control chemist

Procedure: Take out the force gauge to be calibrated and hold vertically up. Adjust the zero on the force gauge. Standard Weights are then applied to the hook of force gauge and measure the tension of the spring on the force gauge. When 1 kg of standard weight is applied, scale on the force gauge should also show 1 kg tension produced from the initial point where pointer is adjusted. Adjust the zero on the force gauge again. Follow the same procedure for other weights Tolerance: 0.25 kg/ 0.1 kg Frequency: Once in 6 months.

Friability test apparatus Friability is the condition of being friable, describes the tendency of a solid substance to break into smaller pieces under contact, especially by rubbing. Friability is defined as the % weight loss by tablets due to mechanical action during the test. Minimum weight loss of the tablet should not be Not More Than1% Friability is usually measured by use of Roche Friabilator or tumbler test. Applicable for compressed uncoated tablet & intended to determine the strength of tablet during transportation & storage .The tablets should retain its shape & size.

Qualification of Friability test apparatus Standard Operating procedure: Department: Quality Control Department Title: Calibration of Friability test apparatus Objective : Objective of this report is to provide documented evidence through the verification of installation, operation and performance of Tablet Friability tester to show that the instrument installed, operated and consistently performed according predetermined specifications. Scope: Procedure applicable for calibration of the friability apparatus Responsibility: Quality control chemist

Procedure: Switch ON the power. The drum will initialize itself to the loading position at the power ON The display will show "start". After the weighing, slide the tablets gently into the drum from the slide slit provided on the drum: (A)tablets with a unit mass equal to or less than 650 mg, take sample of whole tablets corresponding to 6.5 g (B)tablets with a unit mass of more than 650 mg, take a sample of whole 10 tablets. Select the "TIME MODE" or "REVOLUTION COUNT MODE" as desired by pressing the TIME/COUNT key respectively. The MODE indicator LED will indicate the selected mode and press ENTER KEY to register the value.

Press RUN/HALT key to start the test. The drum will start rotating. The display will show elapsed Time or Count on depending on the mode selected. When the test is over, the drum rotates in the reverse direction, discharging the tablets into the tray. Take weight after rotation is completed . Then drum will initialize itself to loading position and display will show "start" indicating that the instrument is ready for the next test. In case during the test, if the user needs to change the Time/Count value, press RUN/HALT key. Pressing the RUN/HALT key again to continue the test . Find out the loss in weight of the tablets(i.e. A-B)

Calculate the percentage of loss by following formula :(A-B) 100 A Find out the percentage loss. Make the entry in the usage log book. Similarly, operate the instrument and count the revolution for calibration as annexure 1.

Observation: Qualification shall be executed using following forms: Annexure- A : Installation verification check list Sl.No Checks to be performed Acceptance criteria 1 Check for the receipt of the consignment It shall be received in good condition 2 Check for any scratches on the machine, body and drums. It shall not have any scratches on machine, body and drums. 3 Check the electrical connection It shall not observed a loose or damage connection.

Annexure- B Calibration of measuring devices Sl No Measuring Criteria Acceptance criteria 1 Vernier calliper It should be calibrated within calibration Period 2 Thermometer It should be calibrated within calibration Period 3 Stopwatch It should be calibrated within calibration Period

Annexure- C Site inspection checklist Sl No Parameters Acceptance criteria 15 to 30 C 40 to 70% -free from vibration -no corrosive gases -free from excess dust -away from direct sunlight Single phase of 230 V AC 50 Hz Shall be provided 1 2 3 Room temperature Room Humidity Room environmental checks 4 5 Point of electrical connection Earthing Annexure- D Utility verification checklist Sl No Parameters Acceptance criteria 1 Phase voltage Single phase,220|230 V AC 50/60 Hz

Tapped density Tester Tapped density The tapped density is an increased bulk density attained after mechanically tapping a container (graduated measuring cylinder) containing the powder sample. It is used to predict both flow properties and its compressibility.

Qualification of Tap density tester Standard Operating procedure Department: Quality Control Department Title: Calibration of Tap density tester Objective: To describe the operation and calibration procedure of Tap density apparatus. Scope: This SOP is applicable to the operation and calibration procedure of Tap density apparatus Responsibility: Officer / Executive - Quality control

Procedure: Ensure that working area is clean and all the connections of instruments are proper. Weigh the sample and fill in a measuring cylinder of tapped density tester If sample weight is about 100g or above, use 250 ml measuring cylinder otherwise use 100 ml measuring cylinder . Fix the measuring cylinder into the holder provided for holding the measuring cylinder on the instrument and Power ON the instrument. The system will initialize itself and the display will flash and show the startup screen. The system is now ready for setting of the test parameter and to run the test. Set the mode of operation as USER.

Press the SET key to set the test parameter. The taps are programmable from 1 to 9999 taps. By using the arrow SET THE TAP VALUE. After setting the tap value, press the START key to start the test. After tapping is complete, check the volume, set the similar number of taps again and run the test once more. Check the volume after second tapping cycle and calculate the difference between the two observed volumes after tapping. If the difference is not less than 2% then continue the tapping for one more cycle and this activity shall be repeated until the difference between succeeding measurement is less than 2%. Frequency : Monthly

User requirement specification for tap density apparatus: Operating criteria must be adequate. Easy maintenance. Equipment should not contain dust. Low cost. Non reactive surface. Capacity (100 ml, 250 ml) Design Qualification (DQ) The following are the key considerations for DQ: Physical dimensions of the equipment and accessories. Suitable operating environment of the instrument. Health and safety requirement.

Installation Qualification (IQ) Details of the equipment: Equipment name, made by & model no. shall be noted down. Location for the installation equipment shall be checked. Utilities required shall be listed down. Any deviation observed during above procedures should be informed for corrective action. Installation procedure: After checking all the specifications as mentioned in the selection criteria, service engineer shall commission the equipment. Authorized validation team shall carry out installation qualification.

Operational Qualification (OQ): Checkthe OQ parameter against their specification Document the deviation details. The quality head and the department head shall decide whether deviation is acceptable or not. . It should support USP I (300 taps/min) and USP II (250 taps/min). It should have simultaneous rotating and tapping motion assures an evenly packed surface. Calculation of test results like tapped density, compressibility index and Hausner ratio. It should have a printer port for documenting test results as per GMP/GLP standards The acoustic cabinet reduces the sound level to 71 dB to meet laboratory standards.

Performance qualification (PQ) It is determined by placing a graduated cylinder containing known mass or volume of drug or formulation on a mechanical tapper apparatus, which is operated for a fixed no. of taps until the power bed volume has reached a minimum. Count and check RPM as per international standards

Disintegration apparatus For a drug to be readily available to the body, it must be soluble and form solution For most tablets, the first important step toward solution is break down of one tablet into smaller particles or granules, a process called disintegration. Disintegration Tester is designed for the accurate estimation of disintegration time of tablets as per IP/USP standards. The instrument is designed to test two batches of six tablets, simultaneously

Qualification of Disintegration tester Qualification of Disintegration tester Standard Operating procedure Department: Quality Control Department Title: Calibration procedure for Disintegration apparatus Objective: To calibrate disintegration apparatus Scope: This SOP applies to the disintegration test apparatus in the quality control department Responsibility: Quality control chemist

A. Calibration for Number of Oscillations per minute Take a pre-calibrated stopwatch. Operate the apparatus as per SOP. Start the apparatus and stopwatch simultaneously and count the number of oscillations per minute. Repeat the same for five times and note down the number of oscillations per minute for each time. The oscillations per minute shall be within the limit of 29 to 32 through a distance of 53 to 57 mm throughout the period of operation. Record the observation. B. Calibration for Temperature: Switch on apparatus and turn on the heater by pressing 'ON' key. Set the bath temperature by pressing scroll keys. Wait till the temperature of beaker A and beaker B attain the set value. Screen shall show the set temperature of bath and the temperature of beaker A and beaker B. Take a pre-calibrated thermometer and check the temperature of beaker A and beaker B. Record the observation

C. Timer Calibration Set the timer for 30 minutes. Start the equipment and stop watch simultaneously. Note the stop watch reading immediately when equipment stops and note down the observation. Observed time should not deviate by 1 min of set time. D. Sieve Integrity Test Check the 'integrity' of woven stainless steel cloth (sieve) attached to the base plate of each basket with a pre- calibrated vernier caliper. The sieve has weaven squares of aperture of 1.8 -2.2 mm and wire diameter of 0.57 to 0.66 mm. Note the observations. Affix the 'CALIBRATION STATUS' and signed on the equipment after completion of calibration. If the instrument is out of calibration then affix 'UNDER MAINTENANCE' tag and inform to maintenance department. Frequency: Once in a month or after each maintenance.

User requirement qualification( URS) for Disintegration test apparatus: Operating criteria must be adequate. Easy maintenance. Equipment should not contain dust. Low cost. Spares should be easily available. Non reactive surface. Audio visual indicators for system status. Printer attachment facility. Operational Qualification (OQ) Check the OQ parameters carefully. Document the deviation details. The quality head and the department head shall decide whether deviation is acceptable or not.

Site inspection checklist: System Digital Tablet Disintegration Apparatus 30 RPM 2 RPM Up and Down speed Accuracy 2% Operating temp. range 0 - 100 C Power 230 10 %, 50 Hz AC Dimensions 450 mm (H) 300 mm (W) 320 mm (L) (approx.) Weight 8 ltrs ( approx.) Performance Qualification (PQ) Ensure the apparatus is properly connected to the power supply When the power is switched on, the timer and temp. shows digital value. Fill the beaker of apparatus with purified water and adjust the temp. between 37 + 2 C.

Fix the beaker in its position and adjust the level of water. Start the basket- rack assembly and timer simultaneously Place the standardized calibrated thermometer to record the actual temp. against the temp displayed. Note the temp. of water in the beaker and oscillation per minute of the basket- rack assembly. Switch OFF the apparatus and record the observation in the calibration record. Acceptance criteria The temp. shall be between 37 2 C The frequency of basket rack shall be between 29 to 32 cycles per minute.

Dissolution apparatus Dissolution The process by which a known amount of drug substance goes into solution per unit of time under standard conditions. Dissolution testing is used as a quantitative tool to provide measurements of the bioavailability of a drug as well as to demonstrate bioequivalence from batch-to- batch.

Qualification of Dissolution Apparatus Standard Operating procedure Department: Quality Control Department Title: Calibration procedure for Dissolution test apparatus Objective : To provide a procedure for the calibration and validation of dissolution test apparatus. Scope: Procedure describes how to validate the centering of paddle and basket rod with that of jar, temperature of test medium throughout the test revolution per minutes of paddle or basket shaft as well as the distance between paddle and jar bottom. Responsibility: Quality control chemist

The instrument shall be calibrated for RPM and Temperature. For Temperature Calibration: Measure the temperature of the water bath and each jar with a calibrated thermometer and compare the result against the digital display on the apparatus. Acceptance Criteria: 37 C 0.5 C For RPM Calibration: Calibrate the apparatus at 50 and 100 RPM. Compare the RPM shown on the digital display of the apparatus with the RPM measured with a stopwatch or Tacometer. Acceptable criteria: 1 RPM - for 50 RPM 2 RPM - for 100 RPM Frequency: Monthly

Installation Qualification Details of the equipment Supplier or manufacturer name and address Equipment name and model no In-house equipment code no. Location Utilities Procedure Site inspection, environmental conditions Parts identification list Validation of physical parameter SOPs Computerized system

Operational Qualification Procedure Power ON check Lift movement check Temperature accuracy Accuracy of shaft rotation Control of paddle wobbling Control of paddle centering Control of distance of shaft to side vessel For automated dissolution system Software/hardware communication Operator interface functions Stress/boundary/challenge testing

Performance Qualification Procedure Test must be conducted for each of the combinations of vessels and apparatus. USP calibrator tablets are used: Disintegrating Tablets (Prednisone) Non- disintegrating Tablets (Salicylic acid) Effectiveness of dissolution will be qualified by determining drug content in the solution . For the comparision , solution of known concentration of USP references standards is used. Document the deviation details. Frequency After each test weekly Procedure\Parameter Clean up the system Inspect: Circulating water pump Bath water Replace bath water Check temperature calibration of the system ,Inspect- guide rods & spindle bearings Inspect: belts & idler pulleys Replace the belts monthly Every 6 month annually Every 2 Years

References: 1) Jain, K. and Bharkatiya, M., 2018. Qualification of Equipments: A Systematic Approach. International Journal of Pharmaceutical Erudition, 8(1), pp.7-14. 2) Kapoor, D,. Vyas, RB. . & Dadrwal, D,. 2018. An Overview of Analytical Instrument Qualification with Reference of Pharmaceutical Industry. Journal of Drug Delivery and Therapeutics, 8(5), pp.99-103. 3) Frost, S.M.A., 2004. Introduction to the Validation of a Dissolution Apparatus. Dissolution Technologies, 11(1), pp.19-21. 4) Bansal, S.K. et al., 2004. Qualification of analytical instruments for use ni the pharmaceutical industry: A scientific approach. AAPS PharmSciTech, 5(1), pp.151-158. 5. Potdar, M. and Dubey, R., 2018. GMP: Current Good Manufacturing Practices for Pharmaceutical. 2nd ed. Pharmamed press, pp.444 446.