Laminate Ply-by-Ply Failure Analysis in Composite Materials

Explore the detailed design and analysis of a laminate ply-by-ply failure process for a Graphite/Epoxy composite, considering the fiber direction, load application, and material properties. Learn about strain calculations, Tsai-Wu criteria, and ply-specific maximum strain values. Gain insights into determining failure loads for undamaged and damaged plies in this comprehensive study by Dr. Autar Kaw.

Uploaded on | 1 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Chapter 5 Design and Analysis of a Laminate Ply by Ply Failure Dr. Autar Kaw Department of Mechanical Engineering University of South Florida, Tampa, FL 33620 Courtesy of the Textbook Mechanics of Composite Materials by Kaw

Fiber Direction x y FIGURE 4.1 Schematic of a lamina z If a ply fails, has the whole laminate failed? Maybe. When the first ply fails, you may get catastrophic failure or you may be able to still apply for more load.

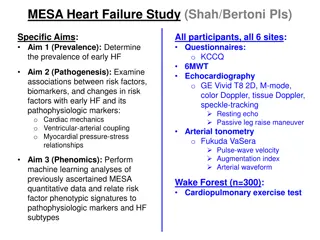

The only load applied is a tensile normal load in the x-direction, that is, the direction parallel to the fibers in the 0o ply. Find the ply-by-ply failure load for a [0/90/0] Graphite/Epoxy laminate. Assume the thickness of each ply is 5 mm and use properties of unidirectional Graphite/Epoxy lamina from Table 2.1. 0o z = -2.5mm z = -7.5mm 5mm 90o 5mm z = 2.5mm 0o 5mm z z = 7.5mm

Assume we apply Nx=1 N/m Mid-plane strains (midplane curvature are zero) 0 x 10 5 353 . 10 11 0 y 2 297 . 10 = 0 0 xy

Ply# Position 1 2 12 1 (00) 9.726 101 9.726 101 9.726 101 1.313 100 1.313 100 1.313 100 Top Middle Bottom 0.0 0.0 0.0 2 (900) -2.626 100 -2.626 100 -2.626 100 5.472 100 5.472 100 5.472 100 Top Middle Bottom 0.0 0.0 0.0 3 (00) 9.726 101 9.726 101 9.726 101 1.313 100 1.313 100 1.313 100 Top Middle Bottom 0.0 0.0 0.0

Ply# Position Maximum Strain Tsai-Wu 1.548 107 (1T) 1.548 107 (1T) 1.548 107 (1T) 7.254 106 (2T) 7.254 106 (2T) 7.254 106 (2T) 1.548 107 (1T) 1.548 107 (1T) 1.548 107 (1T) 1.339 107 1.339 107 1.339 107 7.277 106 7.277 106 7.277 106 1.339 107 1.339 107 1.339 107 1 (00) Top Middle Bottom 2 (900) Top Middle Bottom 3 (00) Top Middle Bottom

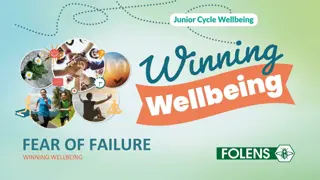

Nx=(1 N/m)x(7.277x106) =7.277x106 N/m Nx/h = 7.277x106/0.015 = 485.1 MPa ox = (5.353x10-10)x(7.277x106) = 0.003895

Q for the undamaged plies 181 8 2 897 0 . . Q [ = ] 2 897 10 35 0 . . GPa 0 0 7 . 17 z = -7.5mm Q for the damaged plies 0 0 0 0o 5mm z = -2.5mm 90o = 5mm [ ] 0 0 0 GPa Q z = 2.5mm 0o 5mm 0 0 0 z z = 7.5mm

Assume we apply Nx=1 N/m Mid-plane strains (midplane curvatures are zero) 1 y - = 0 x 10 - 5 525 . 10 0 10 - 547 . 10 0 0 xy

Ply# Position 1 2 12 1 (00) 1.0000 102 1.0000 102 1.0000 102 Top Middle Bottom 0.0 0.0 0.0 0.0 0.0 0.0 2 (900) Top Middle Bottom --- --- --- --- --- --- --- --- --- 3 (00) 1.0000 102 1.0000 102 1.0000 102 Top Middle Bottom 0.0 0.0 0.0 0.0 0.0 0.0

Ply# Position Max Strain Tsai-Wu 1 (00) 1.5000 107 (1T) 1.5000 107(1T) 1.5000 107(1T) 1.5000 107 1.5000 107 1.5000 107 Top Middle Bottom 2 (900) Top Middle Bottom --- --- --- --- --- --- 3 (00) 1.5000 107(1T) 1.5000 107(1T) 1.5000 107(1T) 1.5000 107 1.5000 107 1.5000 107 Top Middle Bottom

Nx=(1 N/m)x(1.5x107) =1.5x107 N/m Nx/h = 1.5x107/0.015 = 1000 MPa ox = (5.525x10-10)x(1.5x107) =0.008288

1500 1200 Normal Stress, Nx/h (MPa) Last Ply Failure 900 117 GPa 600 First Ply Failure 124 GPa 300 0 0 0.005 0.01 FIGURE 5.1 Stress-strain curve showing ply-by-ply failure of a laminated composite Normal Strain, ex