Lean Six Sigma Principles and Values Overview

Explore the history, core values, and principles of Lean Six Sigma, understanding the foundation of continuous improvement, waste elimination, respect, and pursuit of perfection. Learn about key tools, techniques, and comparative best practices essential for Lean projects.

Uploaded on | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

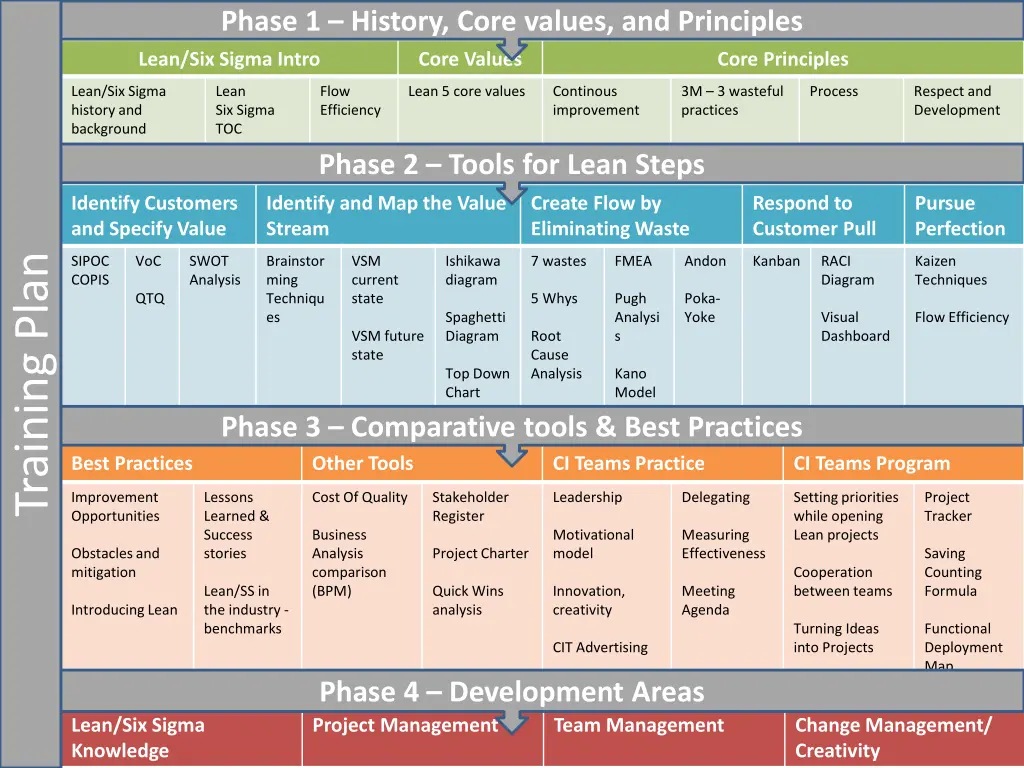

Phase 1 History, Core values, and Principles Lean/Six Sigma Intro Core Values Core Principles Lean/Six Sigma history and background Lean Six Sigma TOC Flow Efficiency Lean 5 core values Continous improvement 3M 3 wasteful practices Process Respect and Development Phase 2 Tools for Lean Steps Identify Customers and Specify Value Identify and Map the Value Stream Create Flow by Eliminating Waste Respond to Customer Pull Pursue Perfection Training Plan SIPOC COPIS VoC SWOT Analysis Brainstor ming Techniqu es VSM current state Ishikawa diagram 7 wastes FMEA Andon Kanban RACI Diagram Kaizen Techniques QTQ 5 Whys Pugh Analysi s Poka- Yoke Spaghetti Diagram Visual Dashboard Flow Efficiency VSM future state Root Cause Analysis Top Down Chart Kano Model Phase 3 Comparative tools & Best Practices Best Practices Other Tools CI Teams Practice CI Teams Program Improvement Opportunities Lessons Learned & Success stories Cost Of Quality Stakeholder Register Leadership Delegating Settingpriorities while opening Lean projects Project Tracker Business Analysis comparison (BPM) Motivational model Measuring Effectiveness Obstacles and mitigation Project Charter Saving Counting Formula Cooperation between teams Lean/SS in the industry - benchmarks Quick Wins analysis Innovation, creativity Meeting Agenda Introducing Lean Turning Ideas into Projects Functional Deployment Map CIT Advertising Phase 4 Development Areas Lean/Six Sigma Knowledge Project Management Team Management Change Management/ Creativity

Phase 1 History, Core values, and Principles Lean/Six Sigma Intro Core Values Core Principles Lean/Six Sigma History/Backgro und Describe the history and foundations of Lean/Six Sigma Lean 5 core values Identify Customers and Specify Value Continous improvement Challenge decision based on far-reaching vision Kaizen an improvement that brings a change for better Genshi Gembutsu management by walking around Lean Six Sigma TOC Compare the 3 improvement programs Identify and Map the Value Stream 3M 3 wasteful practices Muda any activity that doesn t bring value to the customer Mura unevenness in operation like the work pace that causes the operator to hurry and then to wait Muri overburdening of resources Flow Efficiency Describe and exemplify this core notion, use charts or workshops to present. Create Flow by Eliminating Waste Process Process Flow create a flow to unveil the problems Pull create only the quality and quantity demanded by the customer Heijunka Level the time and quantity of production Jidoka apply a system of detecting and informing about an abnormal condition or stopping the process after a failure Standardization standardize processes to expedite operation Visual Control present important information visual Respond to Customer Pull Respect and Development Develop and train managers who understand the work and pass the approach of the organization Develop leaders and teams who contribute to the strategy Respect your staff and partners to build trust Pursue Perfection

Phase 2 Tools for Lean Steps Identify Customers and Specify Value Identify and Map the Value Stream Create Flow by Eliminating Waste Respond to Customer Pull Pursue Perfection SIPOC (COPIS) Presentation + Workshop Brainstorm ing Techniques Present available brainstorming techniques. Workshop. 7 wastes Present the 7 wastes in an appealing way Kanban Describe the kanban cards + beer game Kaizen Techniques Usage of Kaize incremental steps, importance of Control after the execution VoC Client types, questionnaires, values and numbers, Measuring, variation factors, tolerance VSM current state and VSM future state Describe the method, present the scenarios, workshop, focus points, match to other tools (Ishikawa). RACI Diagram Present the tool, usage scenarios Flow Efficiency Describe and exemplify this core notion, use charts or workshops to present. CTQ Comparing tolerance with processes capabilities Ishikawa diagram Man, Material, Machine, Method, Management, Mother nature FMEA Pugh Analysis Kano Model Describe the method + workshop Visual Dashboard Present importance of visual display with examples: Andon screens, FIFO visuals etc. Standards Control phase and Standarizatio n techniques (POT, SOP, web 2.0 processes) SWOT Analysis Strengths, weaknesses, Opportunities, Threats Spaghetti diagram Theoretical description + Workshop 5 Whys Presentation on the tools and workshop Root Cause Analysis Top Down chart Theoretical description + Workshop Andon Poka-Yoke Compare Andon, Poka Yoke, Quality Reviews

Phase 3 Comparative Tools and Best Practices Best Practices, Lessons Learned Other Tools Continuous Improvement Teams Practice Continuous Improvement Teams Program Strategies for defining Improvement Opportunities meeting with an experienced Lean/Six Sigma practitioner How to browse the internal processes to find out mudas/improve ment scenarios. Cost Of Quality Present the Cost of Quality and COPQ structure, cost estimation, counting methods. Can be followed by a workshop. Leading meetings with the focus on creative thinking and enthusiasm. Present creative techniques, brainstorming options, innovative thinking methods. Setting priorities while choosing, opening Lean projects Present the quick wins analysis, Present the FACTS- BENEFITS- VOIDANCE tool. Most frequent obstacles while introducing improvements and mitigation scenarios for them Risks, issues, obstacles during Lean incorporation presenter s choice. FMEA Pugh Kano Present the comparison between those three methods, workshop included. Effective teamwork, sharing responsibilities and motivation, delegating tasks. Effective team leadership. Cooperation between gemba specialists, macro, training committees. Contact the parties and allow cooperation Analysis comparison Beginning of the Lean introduction sharing best practices Introducing Lean (obstacles, best practices) presenter s choice. Communication with Stakeholders Stakeholder Register Present the stakeholder register (workshop). Measuring effectiveness of the actions metrics, indicators, methods. COPQ, Tracker, Savings formula, estimating, workload balancing. Six Sigma tools (Pareto, Statistics) How to effectively push the implementation of the Lean ideas. Present the FACTS- BENEFITS- VOIDANCE tool Sharing project introduction success stories/lessons learned Presentation of internal best practices presenter s choice. Project Charter Show examples, present the rationale, potential workshop. How to run an effective CIT meeting Present the agenda, brainstorm meeting discussion points. Project Tracker Explain the rationale, create and open the project tracker. Lean/SS in the industry best practices Compilation of best practices presenter s choice. How to promote CIT in the department. Motivational criteria. Functional Deployment Map how to create effectively Guide/worksho p through the creation and potential.

Phase 4 Development Areas Lean/Six Sigma Knowledge Project Management Team Management Change Management/ Creativity These 4 pillars represent the major development areas for a Continuous Improvement Team Leader or Green Belt/Black Belt. Each trainings provided in Phases 1-3 fall into one or more of these categories however a dedicated training wave is recommended for each pillar. This table should be individually completed by the trainee.