Macromechanical Analysis of a Lamina and Stiffness Matrices

Explore the macromechanical analysis of a lamina and dive into the 3D stiffness and compliance matrices, presented by Dr. Autar Kaw from the Department of Mechanical Engineering at the University of South Florida. Discover the complexities of laminates and stiffness matrices in composite materials through detailed illustrations and explanations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Chapter 2 MacromechanicalAnalysis of a Lamina Part 3 3D Stiffness and Compliance Matrices Dr. AutarKaw Department of Mechanical Engineering University of South Florida, Tampa, FL 33620 Courtesy of the Textbook Mechanics of Composite Materials by Kaw

FIGURE 2.1 Typical laminate made of three laminas

S S S S S S 1 11 12 13 14 15 16 1 S S S S S S 2 21 22 23 24 25 26 2 S S S S S S 3 3 31 32 33 34 35 36 = S S S S S S 23 23 41 42 43 44 45 46 S S S S S S 31 51 52 53 54 55 56 31 S S S S S S 12 61 62 63 64 65 66 12

C C C C C C 1 11 12 13 14 15 16 1 C C C C C C 2 21 22 23 24 25 26 2 C C C C C C 3 3 31 32 33 34 35 36 = C C C C C C 23 23 41 42 43 44 45 46 C C C C C C 31 51 52 53 54 55 56 31 C C C C C C 12 61 62 63 64 65 66 12 Stiffness matrix [C] has 36 constants

0 0 0 S S S 11 12 12 1 1 0 0 0 S S S 12 11 12 2 2 0 0 0 S S S 12 11 3 12 3 = 0 0 0 ) 0 0 S ( 2 S 12 23 11 23 0 0 0 0 ) 0 S ( 2 S 31 12 31 11 0 0 0 0 0 ) S ( 2 S 12 12 12 11

0 0 0 C C C 11 12 12 1 1 0 0 0 C C C 12 11 12 2 2 0 0 0 C C C 12 11 3 12 3 = 0 0 0 ) 0 0 C ( 2 C 12 23 11 23 0 0 0 0 ) 0 C ( 2 C 31 12 31 11 0 0 0 0 0 ) C ( 2 C 12 12 12 11

1 0 0 0 E E E 1 0 0 0 E E E 1 1 1 0 0 0 2 2 E E E 3 3 = 0 0 0 1 0 0 23 23 G 31 31 0 0 0 0 1 0 12 12 G 0 0 0 0 0 1 G

E(1 - ) E E 0 0 0 (1 - 2 )(1 + ) (1 - 2 )(1 + ) (1 - 2 )(1 + ) x x E E(1 - ) E 0 0 0 y y (1 - 2 )(1 + ) (1 - 2 )(1 + ) (1 - 2 )(1 + ) z z = , E E E(1 - ) 0 0 0 yz yz (1 - 2 )(1 + ) (1 - 2 )(1 + ) (1 - 2 )(1 + ) zx zx 0 0 0 G 0 0 xy xy 0 0 0 0 G 0 0 0 0 0 0 G

S S S S S S 1 11 12 13 14 15 16 1 S S S S S S 2 21 22 23 24 25 26 2 S S S S S S 3 3 31 32 33 34 35 36 = S S S S S S 23 23 41 42 43 44 45 46 S S S S S S 31 51 52 53 54 55 56 31 S S S S S S 12 61 62 63 64 65 66 12

C C C C C C 1 11 12 13 14 15 16 1 C C C C C C 2 21 22 23 24 25 26 2 C C C C C C 3 3 31 32 33 34 35 36 = C C C C C C 23 23 41 42 43 44 45 46 C C C C C C 31 51 52 53 54 55 56 31 C C C C C C 12 61 62 63 64 65 66 12 Stiffness matrix [C] has 36 constants

FIGURE 2.11 Transformation of coordinate axes for 1-2 plane of symmetry for a monoclinic material

FIGURE 2.12 Deformation of a cubic element made of monoclinic material

FIGURE 2.13 A unidirectional lamina as a monoclinic material with fibers arranged in a rectangular array

0 0 S S S S 11 12 13 1 16 1 0 0 S S S S 2 12 22 23 26 2 0 0 S S S S 3 23 33 3 13 36 = 0 0 0 0 S S 23 23 44 45 0 0 0 0 S S 31 31 55 45 0 0 S S S S 12 66 12 16 26 36

0 0 C C C C 11 12 13 1 16 1 0 0 C C C C 2 12 22 23 26 2 0 0 C C C C 3 23 33 3 13 36 = 0 0 0 0 C C 23 23 44 45 0 0 0 0 C C 31 31 55 45 0 0 C C C C 12 66 12 16 26 36

FIGURE 2.14 Deformation of a cubic element made of orthotropic material

0 0 0 S S S 1 11 12 13 1 0 0 0 S S S 2 12 22 23 2 0 0 0 S S S 3 23 33 3 13 = 0 0 0 0 0 S 23 23 44 0 0 0 0 0 S 31 55 31 0 0 0 0 0 S 12 66 12

0 0 0 C C C 1 11 12 13 1 0 0 0 C C C 2 12 22 23 2 0 0 0 C C C 3 23 33 3 13 = 0 0 0 0 0 C 23 23 44 0 0 0 0 0 C 31 55 31 0 0 0 0 0 C 12 66 12

1 0 0 0 12 13 E E E 1 1 1 1 0 0 0 21 23 E E E 2 2 2 1 1 1 0 0 0 2 2 31 32 E E E 3 3 3 3 3 = 0 0 0 1 0 0 23 23 G 23 31 31 0 0 0 0 1 0 12 12 G 31 0 0 0 0 0 1 G 12

+ + 1 0 0 0 23 32 21 23 31 31 21 32 E E E E E E 2 3 2 3 2 3 1 1 + + 1 0 0 0 21 23 31 13 31 32 12 31 2 2 E E E E E E 2 3 1 3 1 3 3 3 = + + 1 0 0 0 31 21 32 32 12 31 12 21 23 23 E E E E E E 1 2 2 3 1 3 31 31 0 0 0 0 0 G 23 12 12 0 0 0 0 0 G 31 0 0 0 0 0 G 12

FIGURE 2.15 A unidirectional lamina as a transversely isotropic material with fibers arranged in a rectangular array

0 0 0 S S S 1 11 12 12 1 0 0 0 S S S 2 12 22 23 2 0 0 0 S S S 3 23 22 12 3 = 0 0 0 0 0 S ( 2 S 23 23 ) 23 22 0 0 0 0 0 S 31 31 55 0 0 0 0 0 S 12 55 12

0 0 0 C C C 11 12 12 1 1 0 0 0 C C C 12 22 23 2 2 0 0 0 C C C 23 22 12 3 3 = 2 0 0 0 0 0 C C 22 23 23 23 31 31 0 0 0 0 0 C 55 12 12 0 0 0 0 0 C 55

0 0 0 S S S 11 12 12 1 1 0 0 0 S S S 12 11 12 2 2 0 0 0 S S S 12 11 3 12 3 = 0 0 0 ) 0 0 S ( 2 S 12 23 11 23 0 0 0 0 ) 0 S ( 2 S 31 12 31 11 0 0 0 0 0 ) S ( 2 S 12 12 12 11

0 0 0 C C C 11 12 12 1 1 0 0 0 C C C 12 11 12 2 2 0 0 0 C C C 12 11 3 12 3 = 0 0 0 ) 0 0 C ( 2 C 12 23 11 23 0 0 0 0 ) 0 C ( 2 C 31 12 31 11 0 0 0 0 0 ) C ( 2 C 12 12 12 11

1 0 0 0 E E E 1 0 0 0 E E E 1 1 1 0 0 0 2 2 E E E 3 3 = 0 0 0 1 0 0 23 23 G 31 31 0 0 0 0 1 0 12 12 G 0 0 0 0 0 1 G

E(1 - ) E E 0 0 0 (1 - 2 )(1 + ) (1 - 2 )(1 + ) (1 - 2 )(1 + ) x x E E(1 - ) E 0 0 0 y y (1 - 2 )(1 + ) (1 - 2 )(1 + ) (1 - 2 )(1 + ) z z = , E E E(1 - ) 0 0 0 yz yz (1 - 2 )(1 + ) (1 - 2 )(1 + ) (1 - 2 )(1 + ) zx zx 0 0 0 G 0 0 xy xy 0 0 0 0 G 0 0 0 0 0 0 G

Independent Elastic Constants Material Type Anisotropic 21 Monoclinic 13 Orthotropic 9 Transversely Isotropic 5 Isotropic 2

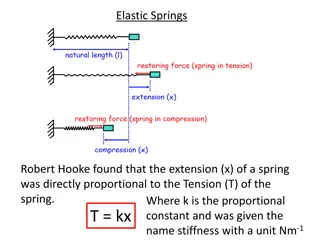

= , , 0 0 3 0 = = 31 23 Upper and lower surfaces are free from external loads , 0 = 31 23 3 0 , 0 , = = FIGURE 2.17 Plane stress conditions for a thin plate