Management of Physical Distribution in Marketing

Physical distribution is a crucial aspect of marketing management that involves the movement and storage of goods from production to consumption. Learn about the definitions, characteristics, and importance of physical distribution in increasing sales volume and creating utilities for consumers.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

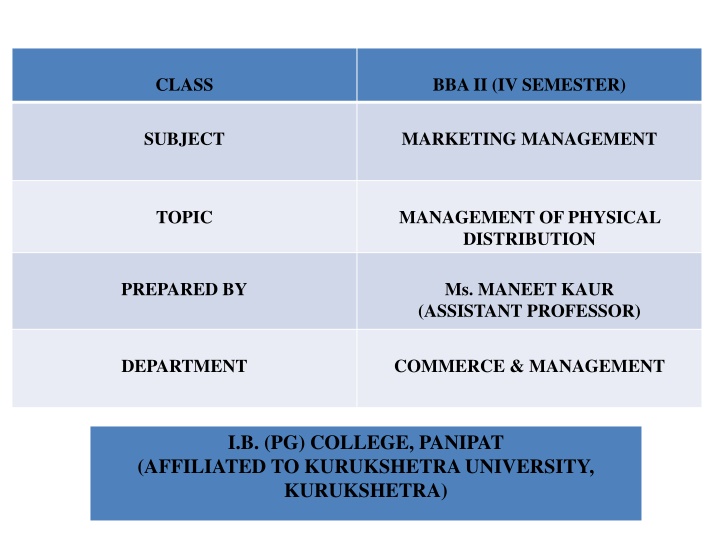

CLASS BBA II (IV SEMESTER) SUBJECT MARKETING MANAGEMENT TOPIC MANAGEMENT OF PHYSICAL DISTRIBUTION PREPARED BY Ms. MANEET KAUR (ASSISTANT PROFESSOR) DEPARTMENT COMMERCE & MANAGEMENT I.B. (PG) COLLEGE, PANIPAT (AFFILIATED TO KURUKSHETRA UNIVERSITY, KURUKSHETRA)

INTRODUCTION It is a major task to create a customer but the critical task is to deliver the product created by the organization to the customer. If the product is not available when and where customer wants it, it is sure to fail in the market. Generally firms have a distributive activity within the organization structure known ad Logistics , or Marketing Logistics or Physical Distribution Management.

DEFINITIONS OF PHYSICAL DISTRIBUTION Physical distribution involves the actual movement and storage of goods after they are produced and before they are consumed. -Cundiff and Still Physical distribution involves planning, implementing and controlling the physical flow of materials and final goods from point of origin to the point of use to meet customer needs at a profit . - Philip Kotler

CHARACTERISTICS OF PHYSICAL e DISTRIBUTION Physical distribution is a marketing activity that relates with handling and movement of raw materials & finished goods from the manufacturer to the consumers through the intermediaries. Physical distribution is a science of logistics. Physical distribution creates time and place utility by storage of products after their production and before their consumption. physical distribution includes transportation of products to the consumers and thus maximising the value of products by delivering them to the right consumers at the right time and right place. Physical distribution includes the management of various activities like material handling, inventory transportation, warehousing, protective packaging, warehouse location, market forecasting and customer service. control, order processing, plant and

IMPORTANCE OF PHYSICAL DISTRIBUTION INCREASE IN SALES VOLUME: Due to efficient function of physical distribution, a company can increase its sales volume. Reduction in distribution cost, low inventory, larger market share, prize stabilisation, improvement in satisfaction to consumers are such factors which are responsible for increasing sales volume of the company. CREATION OF UTILITES: Physical distribution is the creation of time, place and possession utilities. Time utility can be created by storage of additional production in the warehouses. Place utility can be created with the help of transportation by delivery the products to the consumers and possession utility can be created through transfer of title of the products. i. customer service and more ii.

CONTINUED iii. LARGER MARKET SHARE: Another major contribution of physical distribution is to acquire large market share by decentralising its warehousing to reach those far-flung market segments which remain untapped as yet. iv. REDUCTION IN DISTRIBUTION COST: A systematic planning of punctual transport schedules, inventory level, efficient warehousing operations and material handling would lead to considerable reduction in distribution cost. Thus, we can say that efficient physical distribution can reduce the total cost.

CONTINUED v. IMPROVEMENTS IN CUSTOMER SERVICE: The main objective of physical distribution is to deliver the right goods to the right customer at the right time and right place. Better physical distribution services give better customer services and higher overall satisfaction to customers. vi. COORDINATION BETWEEN DEMAND AND SUPPLY: physical distribution system establish effective coordination between demand and supply. Quick and modern system makes it possible to transport even the perishable commodities like vegetables, fruits, milk, milk products, etc. at the right place, at the right time in the right quantity. Efficient transportation

COMPONENTS OF PHYSICAL DISTRIBUTION Inventory Control Material Handling Transportation Warehousing Order Proce ssing

TRANSPORTATION Transportation is the physical means whereby products are transferred from the place of production to the place of consumption. It reduces the gap between the consumer and the producer and further serves as an aid to specialisation and large scale production. It creates place utility and assists in widening the markets for a commodity. Goods are physically moved from one place to another according to market needs with the help of transportation.

VARIOUS MODES OF TRANSPORT ROAD TRANSPORT RAIL TRANSPORT WATER TRANSPORT AIR TRANSPORT PIPELINE TRANSPORT

WAREHOUSING A warehouse is a place where surplus goods can be kept safely for future use. It retains the goods in perfect state till they are needed by the consumers and are to be taken to the market. It enables goods to be made available to buyers wherever and whenever they are in demand. Modern warehouses are equipped with latest equipments and facilitates for the safety of goods. It creates time utility.

TYPES OF WAREHOUSES PRIVATE WAREHOUSES: Private warehouses are owned by the manufacturer to store the goods manufactured. These warehouses are privately owned and constructed for the use of the owners only. PUBLIC WAREHOUSES: Public warehouses are those which operate to store goods of the public for an agreed fee. These warehouses do not belong to any particular trader. They are licensed by the state. BONDED WAREHOUSES: These are licensed warehouses which accept imported goods for storage till payment of duty is made. The importer is at advantage of taking delivery of the goods without paying the duty, provided he does so for the purpose of re-export.

CONTINUED HOUSEHOLD WAREHOUSES: In villages surplus agricultural products are stored in kachche houses. The storing place is small and it meets the requirements of the individual family. CO-OPERATIVE WAREHOUSES: The farmers or traders can register a co-operative society to set up a co-operative warehouse. Food grains, fruits and vegetables are generally stored in such warehouses. INSTITUTIONAL WAREHOUSES: Because of the nature of their activities, various institutions have their own warehouses. The following are few examples- Bank godowns , railway warehouses, warehouses of F.C.I, government warehouses.

INVENTORY CONTROL It is an important part of the cost production. It may be defined as a systematic control of the procurement, storage and usage of materials so as to maintain a balance between the time and the investment. The material control or inventory control involve following activities: i. Purchase of materials. ii. Receiving of materials. iii. Inspection of materials. iv. Storage of materials. v. Issuing of materials.

DECISIONS TAKEN FOR INVENTORY CONTROL Inventory control is the process of deciding what and how much of various items are to be kept in the stock. Following decisions are taken in this regard: a) MAXIMUM LEVEL: The fixation of maximum level is necessary to avoid unnecessary blocking up of the capital in inventories, losses on account of deterioration and obsolescence of materials. b) MINIMUM LEVEL: The minimum level is the lowest quantity of balance material which must be maintained in hand at all times so that the production line may not be stopped on account of non-availability of materials. c) INVENTORY CARRYING COST: It is the cost of keeping goods in the stock includes interest on investments, insurance premium, etc.

CONTINUED d) RE-ORDERING LEVEL: The re-ordering level is fixed somewhere between the maximum level and the minimum level in such a way that the quantity of materials represented by the difference between the re-ordering level and minimum level will be sufficient to meet the demand of production till such time as the order materialises and supplies are received. e) DANGER LEVEL: It is the level of stock below which the material stock never be allowed to fall in normal circumstances. f) ORDERING COST: It is the cost of placing an order and securing the supplies. The more frequently the orders are placed, lesser the quantity purchased, higher will the ordering cost.

MATERIAL HANDLING Material handling as a human activity is as old as mankind. Material handling is undertaken at every stage of logistics activity namely during production-storage-transport and packaging process. It represents product handling from plant to warehouse and from warehouse to the place of loading. Material handling is the sub-system of physical distribution system of a firm and it helps in cost reduction and improved customer service.

METHODS OF MATERIAL HANDLING MANUAL METHOD: It include the use of man and animal power in moving the products. The use of hand and animal driven trolley and the carts are the finest example of this kind. MECHANICAL METHOD: It involves the use of machines driven by power, these are three types namely, those move along a fixed path like convey our systems; those operating within fixed area like cranes and lifts; those which operate in suitable area like stackers, side-loaders, etc. AUTOMATIC METHOD: These are fully automotive operated by automatic machines and computers.

SELECTION OF METHODS CUSTOMER SERVICE NATURE OF PRODUCT COSTS OF OPERATION RESOURCES

ORDER PROCESSING It is considered as the key to customer service and satisfaction. It includes receiving, recording, filling and assembling of products for dispatch. Customer satisfaction is depend on the time taken by the firm to place the orders. Modern marketing system now using computers system to speed up the order processing. Electronic data expedites order processing and minimises possibility of errors and omissions.