Material Control

Efficient purchasing, receipt, inspection of materials are completed - now focus on proper storage. Learn the key steps for effective material control.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

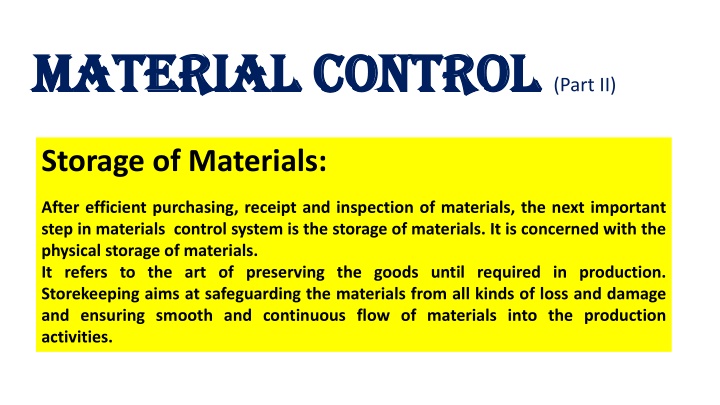

Material Control Material Control (Part II) Storage of Materials: After efficient purchasing, receipt and inspection of materials, the next important step in materials control system is the storage of materials. It is concerned with the physical storage of materials. It refers to the art of preserving the goods until required in production. Storekeeping aims at safeguarding the materials from all kinds of loss and damage and ensuring smooth and continuous flow of materials into the production activities.

Functions of Stores Department: 1. Preparing purchase requisitions for general items of stock. 2. Receiving of goods into stores. 3. Providing security to goods by arranging them at appropriate places. 4. Avoiding damage and deterioration. 5. Classification and coding of materials. 6. Issue of materials to production and service departments. 7. Maintaining stock records& Maintaining proper stock levels. 9. Providing stock information when required. 10. Verifying stock at regular intervals. 11. Minimizing storage handling and maintaining costs. 12. Preventing unauthorized persons in the stores.

Location of the Stores Department: The location of the stores department should be selected carefully keeping in mind the element of cost and efficiency. In Centralized stores, materials are stored in one centrally located store room. But in Decentralized stores, each production department possess separate stores department. Size of the Stores Department: It depends on overall size of the organization, nature of materials, capital employed, space and security required to be provided to the material.

Store Keeper: Store keeper is the in charge of stores department. He is also known as Chief Storekeeper, store superintendent who is responsible to control the stores. He should have an ability to organize the functions of the Stores. Duties of the Store-keeper: 1. Checking and accepting the incoming materials. 2. Keeping every item of stores in its place. The principle of good store keeping is a place for every thing and every thing in its place. 3. Issue materials only against authorized requisitions, in right quantity and quality and at the right time. 4 Maintain stock records with up to date entries of receipts, issues and balances. 5. Prepare purchase requisitions whenever necessary. 6. Maintain the stock levels. 7. Maintain the stores in an orderly manner. 8. Physical stock verification at regular intervals. 9. Restricting unauthorized entry into the stores 10. Furnish stock information to the management, regarding waste and scrap material, obsolete stock etc.

Methods of Coding: I. Alphabetical method II. Numeric method III. Alpha- numeric method Advantages of codification: 1. It helps in easy identification of materials. 2. It removes ambiguities in description of materials. 3. It saves time in handling materials. 4. It reduces clerical work in writing full description of materials. 5. Codification is a must for mechanized accounting 6. It ensures secrecy as code numbers are not known to all.

Inventory Control: As stated earlier inventory comprises stock of raw materials, work-in-progress, finished goods, tools, equipment and components. Inventory control means control over different components of the stock. It is defined as Physical control of stock items and implementing the principle and policies relating thereto'. It aims at the optimum utilization of financial resources of the continuous flow of materials into the production activities. Important Inventory Control Techniquesare: 1. Fixation of stock levels 2. EOQ 3. ABC analysis 4. Perpetual inventory system 5. Establishment of systems of budgets 6. Provisioning and procedures 7. Control ratios

Fixation of Stock Levels: Material control aims at providing enough materials to the production activities without any delay and stoppage of production activities. It also aims at keeping the investment in inventory at the lowest possible level. Stock carrying cost (e.g. interest on capital, go down rent. insurance expenses, deterioration in quality and quantity) is more in case of over-stocking. In contrast, cost of placing orders, getting the supplies and the fear of scarcity (out of stock) are more in the case of purchases made in small scale.

Maximum Stock Level = (Reorder Level + Reorder Quantity) - (Minimum Consumption X Minimum Delivery Time) OR Maximum Stock Level =(Reorder Level + EOQ) -(Minimum Consumption X Minimum Reorder Time) Minimum Stock Level Minimum level = Reorder level-(Normal Consumption x Normal Delivery Time) ( Consumption' is also known as 'usage' & Normal delivery time is known as Average Delivery Time or normal reorder period or reorder period) Here,Normal Consumption = Maximum Consumption + Minimum Consumption 2 Normal Delivery Time = Maximum Delivery Time+ Minimum Delivery Time 2

Reorder level= Maximum Consumption X Maximum Delivery Time OR Reorder level = Minimum stock Level + (Normal Consumption X Normal Delivery Time) Danger level= Average consumption X Emergency delivery period. Hint: The term Average or Normal both are one and the same. Hint: Average stock level is calculated as follows: Average stock level: = (Maximum stock level + Minimum stock level) + 2 or Average stock level=Minimum level + Reorder quantity

EOQ (Economic Order Quantity): It is that Quantity of material at which cost is equal to the revenue. It is that cost at which the carrying cost as well as the ordering costs would be very minimum . EOQ is the optimum or the most favourable quantity to be bought at each order. It sets equilibrium between carrying costs and ordering costs. At this point the carrying and the ordering costs are equal and the total cost is the lowest. ABC analysis of stock (also known as Always Better Control technique): A category represents 5% to 10% of the total items in the stores and 70% to 85% of the total inventory value. "B category constitutes 20% to 30% of the inventory items and 25% to 30% of the stores value and the 'C' category constitutes 70% to 80% of the total items representing 5% to 10% of the stores value.

Perpetual Inventory System: The most important tool of inventory control is the perpetual inventory control is the perpetual inventory system. It is a method of recording the stores issues and balances on daily basis after undertaking the checking or reification of stock on daily basis. The main intension is to monitor the excess and entry of stock. The main two features being:- i. Continuous stock recording & ii.Continuous stock verification The differences between bin card and stores ledger are as under: Bin Card Stores Ledger 1. Maintained by stores Dept. 2. Attached to the Bin 3. Records quantities only. 4. Transactions are posted continuously 5. Each transaction is entered individually Maintained by Cost Accounting Dept Kept in the cost office. Records both quantities & values Sometimes posted periodically. Transactions may be posted summarily. Inter job / department transfers are also entered for costing purpose 6. Inter department/ job transfers are not entered.

I. STORAGE OF MATERIAL II.FUNCTIONS OF STORES DEPARTMENT III.LOCATION AND SIZE OF STORES DEPARTMENT IV.STORE KEEPER V.CODING VI.IMPORTANT INVENTORY CONTROL TECHNIQUES VII.FIXATION OF STOCK LEVELS VIII.EOQ ABC ANALYSIIS IX.PERPETUAL INVENTORY CONTROL SYSTEM X.DIFFERNCE BETWEEN STORES LEDGER AND BIN CARD

Thank you Thank you