Modeling of Transformer Vacuum Drying Process and Mathematical Analysis

This research paper focuses on modeling the transformer vacuum drying process for removing moisture from main insulation materials to enhance dielectric strength. Mathematical models and simulations are utilized to predict moisture content, optimize process parameters, and analyze the drying process bottleneck. Key aspects include heat and moisture diffusion equations, properties of cellulose insulation, and verification through simulated moisture uptake experiments. The study aims to improve efficiency and reliability in transformer manufacturing.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Modelling of Transformer Vacuum Drying Process Nikola Borovnik, Sa a Mudrini , Nenad Ferdelji University of Zagreb, Faculty of Mechanical Engineering and Naval Architecture, Croatia 19-21 April 2023, Zadar, Croatia

Outline Introduction Methods and procedures Verification Vacuum drying simulation and discussion Conclusion 1/12

Introduction Transformer main insulation: cellulose insulation (pressboard, Kraft paper) + mineral oil Moisture significantly reduces dielectric strength Moisture content should be less than 0.5 % (dry basis) before the oil impregnation process 2/12

Introduction Transformer drying a bottleneck of the manufacturing process Mathematical model: predict final moisture content analyse the influence of process parameters optimize the process 3/12

Methods and procedures mathematical model Heat diffusion (heat equation) + moisture diffusion (Fick s second law) ?2? ??2 Thermal diffusivity for porous material (tortuosity of cellulose fibres) ?f ?f?f? Moisture diffusivity as a function of both moisture content and temperature ?? ??= ?T ?? ??= ? ?? ?? ?? ?M?,? ?f= 1 ln?f ?T= 2 ?ref 1 1 ?M?,? = ?0???+?a ? Differential equations are solved numerically by using backward Euler/central difference scheme 4/12

Methods and procedures mathematical model Cellulose insulation properties (Kraft paper and pressboard are distinguished) Label ?f ?f ?f ? Kraft paper 0.615 W/(m K) 1720 J/(kg K) 1550 kg/m3 633 kg/m3 Pressboard ? Type of insulation ?0 (m2/s) Non-impregnated Kraft paper Non-impregnated pressboard ?a(K) 0.5 8140 2.62 10-11 0.45 7646 0.67 10-12 1250 kg/m3 Kraft paper equilibrium moisture content (empirical relation) ?eq?v,? = 9.8755 10 11?v 0.6685? 4725.6 ? 5/12

Model verification Du et al. simulated a moisture uptake by initially dry pressboard sample (1.5 mm thick) at 70 C (temperature was considered uniform and constant) Initial conditions: ?i= 298.15 K ?i= 0 % Boundary conditions ?? ???=? ?? ???=0 ?? ?? = 0 = 0 ?=? = ? ?s ?process ??=0= 1.8712 % 6/12

Model verification Du model absence of heat diffusion modelling Formulated model insulation initially at 25 C As insulation is warmed up to 70 C the difference between moisture distributions becomes negligible The difference is smaller with increase of heat transfer coefficient 7/12

Vacuum drying simulation Single cycle of vacuum drying is simulated Initial conditions: ?i= 298.15 K ?i= ?eq?H2O ?i,?i 100% Boundary conditions: ?? ???=0 ?? ?? = 0 = 0 ?=0 ?? ???=? ??=?= ?eq(?H2O ?process,?s) 100% = ? ?s ?process 8/12

Vacuum drying simulation Reference case: process temperature 100 C heat transfer coefficient 5 W/(m2K) 40 mm thick insulation Thermal diffusion is much faster process then moisture diffusion 9/12

Vacuum drying simulation Average moisture content of cellulose insulation ? ?avg(?) =1 ? 0 ? ?,? ?? Temperature of the process has a crucial impact on necessary drying time Vacuum application doesn t impact the drying time significantly heat transfer coefficient 5 W/(m2K) 40 mm thick insulation 10/12

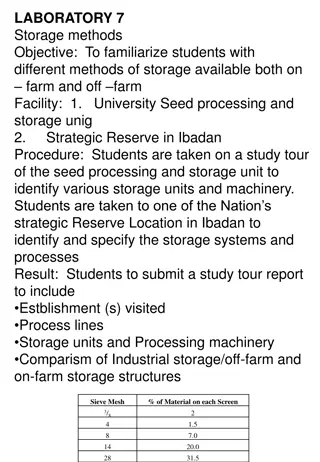

Vacuum drying simulation Average moisture content at the end of 24-hour cycle for various thicknesses and heat transfer coefficients Good insight into the expected state of insulation dryness at the end of process process temperature 115 C atmospheric pressure (101325 Pa) 11/12

Conclusion It is justifiable to assume uniform temperature distribution equal to the temperature of the process Importance of applying heat evenly during the drying process (advantage of vapor phase drying or hot oil drying) Future steps: Influence of vacuum on heat transfer between surface and the medium Effect of local moisture evaporation on temperature field inside insulation 12/12