New Sustainable Resin Data Shows Reduced Carbon Footprint

Cutting-edge LCI data for Unsaturated Polyester (UPR) and Epoxy Vinyl Ester (EVER) resins reveals significant reductions in Global Warming Potential (GWP). A recent LCA study completed by industry leaders demonstrates improved product sustainability through decreased emissions and energy consumption. Explore how advancements in resin chemistry are driving environmental progress in the chemical industry.

Uploaded on | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

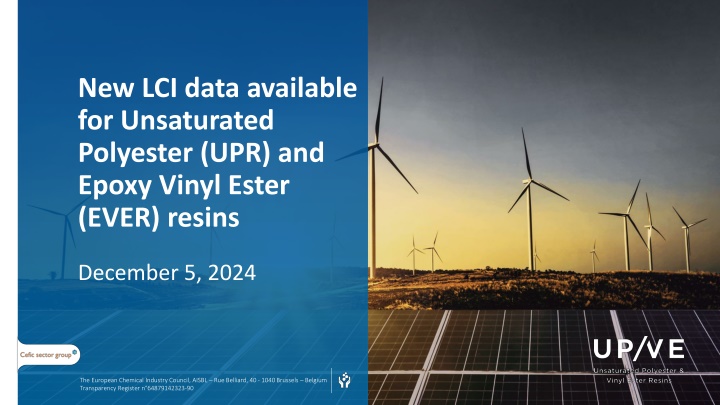

New LCI data available for Unsaturated Polyester (UPR) and Epoxy Vinyl Ester (EVER) resins December 5, 2024 The European Chemical Industry Council, AISBL Rue Belliard, 40 - 1040 Brussels Belgium Transparency Register n 64879142323-90

LCA Study Completed for Main UR and EVER Resin Chemistries Executed by EY consultants AOC, INEOS, Polynt, Scott Bader, SIR provided detailed information on energy consumption, emissions, waste, per plant and per product chemistry EY combined the data and sent average datasets per chemistry to Ecoinvent Ecoinvent calculated footprint for Ortho, Iso, DCPD, Maleic, rPET, and VE resins Not just CO2 (GWP, Global Warming potential), but also other LCI output categories Information published through Ecoinvent release 3.11 (November 2024) GWP of main resin chemistries reduced by 2-8 % (3.11 vs. 3.10) GWP of rPET resins 16 % lower than average of Ortho, DCPD, Iso, and Maleic 2

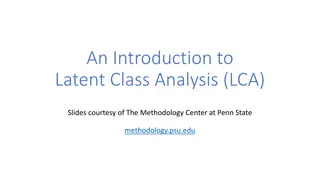

Improvement of Product Carbon Footprint Global Warming Potential (GWP) as per Ecoinvent 3.11 GWP of main UPR and EVER resin chemistries reduced by 2-8 % (3.11 vs. 3.10) 6 5 GWP kg CO2 eq. 4 Ecoinvent 3.10 3 Ecoinvent 3.11 2 1 0 VE DCPD Iso Maleic Ortho 3

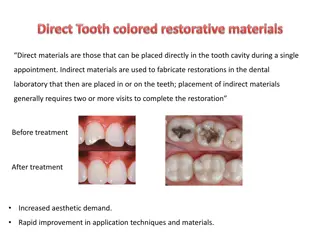

GWP of rPET resins lower than Ortho, DCPD, Iso, and Maleic (average -16 %) Global Warming Potential (GWP) as per Ecoinvent 3.11 3.8 3.6 3.4 GWP of rPET resins lower than Ortho, DCPD, Iso, and Maleic (average -16 %) GWP kg CO2 eq. 3.2 -16 % 3 2.8 2.6 2.4 2.2 2 Iso DCPD Maleic Ortho rPET