Nickel 201 Strip

Technolloy Inc. is a leading manufacturer, supplier, and exporter of premium-quality Nickel 201 Strips. We offer these Nickel 201 Strips in a variety of dimensions and specifications, including both standard and custom forms.nn

Uploaded on | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

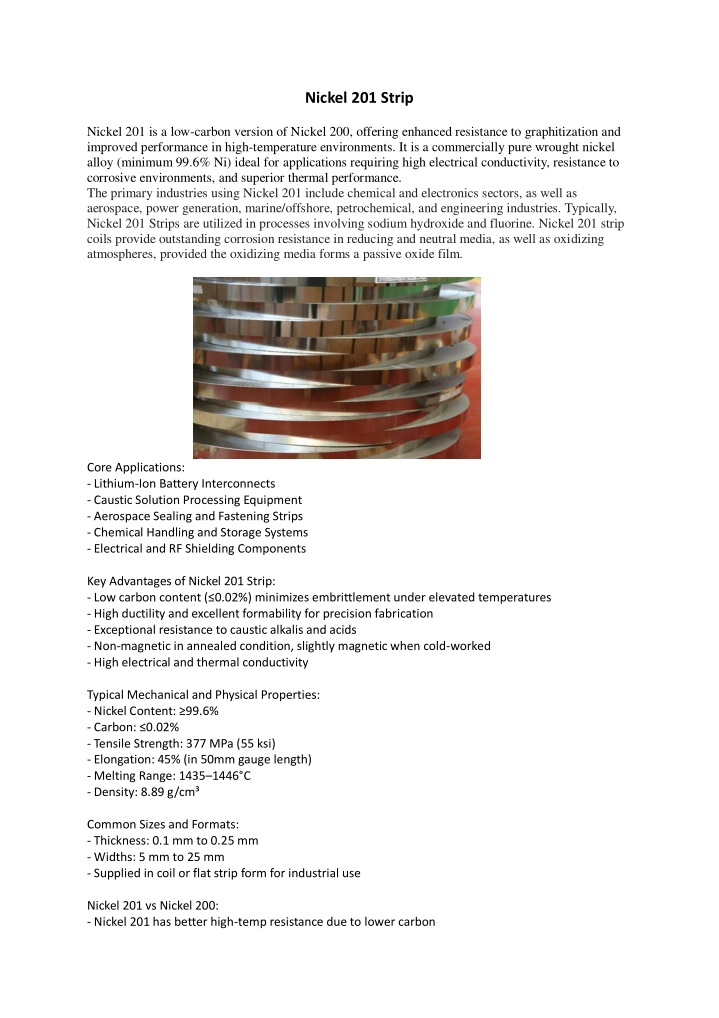

Nickel 201 Strip Nickel 201 is a low-carbon version of Nickel 200, offering enhanced resistance to graphitization and improved performance in high-temperature environments. It is a commercially pure wrought nickel alloy (minimum 99.6% Ni) ideal for applications requiring high electrical conductivity, resistance to corrosive environments, and superior thermal performance. The primary industries using Nickel 201 include chemical and electronics sectors, as well as aerospace, power generation, marine/offshore, petrochemical, and engineering industries. Typically, Nickel 201 Strips are utilized in processes involving sodium hydroxide and fluorine. Nickel 201 strip coils provide outstanding corrosion resistance in reducing and neutral media, as well as oxidizing atmospheres, provided the oxidizing media forms a passive oxide film. Core Applications: - Lithium-Ion Battery Interconnects - Caustic Solution Processing Equipment - Aerospace Sealing and Fastening Strips - Chemical Handling and Storage Systems - Electrical and RF Shielding Components Key Advantages of Nickel 201 Strip: - Low carbon content ( 0.02%) minimizes embrittlement under elevated temperatures - High ductility and excellent formability for precision fabrication - Exceptional resistance to caustic alkalis and acids - Non-magnetic in annealed condition, slightly magnetic when cold-worked - High electrical and thermal conductivity Typical Mechanical and Physical Properties: - Nickel Content: 99.6% - Carbon: 0.02% - Tensile Strength: 377 MPa (55 ksi) - Elongation: 45% (in 50mm gauge length) - Melting Range: 1435 1446 C - Density: 8.89 g/cm Common Sizes and Formats: - Thickness: 0.1 mm to 0.25 mm - Widths: 5 mm to 25 mm - Supplied in coil or flat strip form for industrial use Nickel 201 vs Nickel 200: - Nickel 201 has better high-temp resistance due to lower carbon

- Ideal for high-temperature and high-purity applications Identification and Verification Methods: - XRF Analysis for Nickel Purity - Spark Test: Very light spark production vs steels - Magnetism: Non-magnetic when annealed; test for cold-worked samples - Documentation: Ensure ASTM B162 and material certification for authenticity Industries Utilizing Nickel 201 Strip: - Renewable Energy Storage (battery tabs and connectors) - Chemical manufacturing (handling strong alkalis) - Aerospace (components under thermal and corrosive stress) - Medical Devices (biocompatibility and corrosion safety) - Food Processing (non-contaminating metal equipment) Handling and Storage Best Practices: - Store in dry, non-corrosive environment - Wear gloves to avoid oils and contaminants - Use moisture-proof packaging when shipping Certifications and Standards: - Conforms to ASTM B162 for strip/sheet forms - Often meets ISO 9001, RoHS, and REACH standards Nickel 201 Winding Strip Specification Item Nickel 201 Strip Thickness 0.01, 0.1, 0.2, 0.05, 0.5 per Customer Requirement Size 3, 3.2, 3.5, 3.6, 3.8, 4.5, 4.57, 4.8, 5, 5.2, 5.5, 7.2 mm and as per Customer Requirement Width 3 mm to 350 mm and as per Customer Requirement Length Coil form Standard JIS, AISI, ASTM, GB, DIN, EN, etc Surface Bright Brand: Technolloy Inc Package Shrink-wrapped, Carton boxes, Wooden pallets, Wooden boxes, Wooden crates Etc. as required. Conclusion: Nickel 201 strips are essential in modern industry where high thermal, chemical, and electrical performance are needed. Whether you're building battery modules, chemical plants, or aerospace components, Nickel 201 delivers stability, purity, and resistance under pressure. Always source certified materials and highlight differences from Nickel 200 for optimized SEO targeting. For More Details https://www.nickelstrip.com/nickel-201-strips-manufacturers-suppliers-stockists-exporters.html Contact US: (022) 67437682 If any enquiries please contact us our support team will connect you as soon as possible