Optimizing Steel Production Scheduling with Energy Consideration

Explore integrated scheduling of the rolling sector in steel production, considering energy consumption under time-of-use electricity prices. The study focuses on minimizing production costs, including changeover costs, facility costs, and energy consumption costs in a multi-stage steel production process.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Integrated scheduling of rolling sector in steel production with consideration of energy consumption under time-of-use electricity prices Shengnan Zhao, Lixin Tang. Northeastern University Ignacio Grossmann. Carnegie Mellon University EWO 2017

Background Steel production involves a long process flow with complicated manufacturing techniques We investigate an integrated scheduling of a three-stage process of steel production with consideration of energy consumption under the time-of-use electricity price

Problem Definition Given Sets of jobs with information of : Processing route Processing time at each unit Sequence-dependent changeover costs A set of units at each stage with information of : Processing mode of each unit: batch process or sequential process For batch process: Setup time between adjacent batches Maximum batch capacity Information of energy consumption Unit-dependent electricity consumption per hour Electricity price of a set of discrete time periods

Problem Definition Determine For batch process: Job assignment to the units Batch composition, batch capacity, number of batches at each unit Electricity consumption of each electricity pricing period For sequential process: Coil sequence and timetable at each unit Completion time of the entire production Objective Minimize the total production costs including: Total changeover costs Total rolling facility costs Total energy consumption costs

Proposed MINLP/GDP Model A time-slot based continuous time MINLP model is proposed with GDP constraints Constraints of batch process Assignment and batching: Timing constraints: = = s k s i ' , ,, s k i , sd y s AC k T 1, y i N s , , s k i ac ' ac s AC k T i N s s s k = = + , ,, s k i , nbatch y s AC k T s k , , tf tb sd s AC k T , s k s s k ' ac i N s t s s k 1, + , \ s k r s k r s AC k T + s , , \{ } t tf setup r tb s AC k T , , s + 1 , s k s s k ' tf s s ,, s k r , s k r nbatch nB s AC k T = ' , ,, s k i , ' s tf y i N AC , , max s k s ac i k s AC k T s

Proposed MINLP/GDP Model Constraints of sequential process Allocation constraints: Immediate precedence constraints: = s 1, \ , = , \ , , \{ } t y s S AC i N y , , i j k z s S AC i N k T , , s k i s , , s k i s s s k T j N s s = s 1, \ , = , \ , , \{ } t y s S AC k T y , , i j k z s S AC j N k T , , s k i s , +1, s k j s s s i N i N s s Timing constraints: s s i k , ,, s k i \ , , tb UB y s S AC k T i N s = , \ , tf tf s S AC k T , s s s , i k s k i N s s , ,, s k i \ , , tf UB y s S AC k T i N s s k 1, \ , \{ }, t tf tb s S AC k T i N , i k s s s + s s s k s i tb s s i = , \ , , cd y s S AC k T i N s i k = \ , tb s S AC i N , , s k i s s , s , i k k T s = + s s i k s ,, i k / , , tf tb cd s S AC k T i N s tf s = \ , tf s S AC i N , , i k s s , i k s i k T s s k s i k = , \ , tb tb s S AC k T ' i tf s s i , s , ', ' , tb s S s L i N i N ' s s s

Proposed MINLP/GDP Model Energy consumption constraints = , ,, s k tp T p pwh tp TP Electricity consumption of each time period: tp s s AC k T s = Redundant constraints: , ,, s k tp T , sd s AC k T , s k s tp TP Possible interactions of a slot with a constant time period

Proposed MINLP/GDP Model Energy consumption constraints GDP constraints: , , R R s AC k T , , s k s k s , , s k tp T = 0 , , s k tp A , , s k tp B C , , s k tp s k s k s k s k =0 tb L tp L tp L tp tb cp tb cp tb cp s =0 tf s s s k U tp sd L tp U tp tf cp tf cp tb cp k k k , , s k tp T = s k s s U tp U tp tf cp tf cp k k s s k , , s k tp T = , , s k tp T = L tp U tp tf cp cp tb k D E , , s k tp F , , s k tp , , s k tp s k s k s k L tp L tp U tp tb cp tb cp tb cp , tp TP s s s U tp L tp U tp tf cp tf cp = tf cp = k = k k , , s k tp T , , s k tp T 0 0 U tp L tp , , s k tp T cp cp , , R R s AC k T , , s k s k s , , s k tp B , , s k tp F , , , R , , s k tp A C D E s AC k T tp TP , , , s k tp , , s k tp , , s k tp s k s , , , , , , { , } R , , s k tp A , , s k tp B C D E , , s k tp F True False , , , s k tp , , s k tp , , s k tp s k

Proposed MINLP/GDP Model Objective function = s s buy tp 1 + 2 m + 3 m obj m F z c s k r ce p , roller tp , , i j k ij s S AC i N j N k T s AC k T tp TP / s s s s Estimation of slot number ac = = sn NB The number of slots is estimated by: least nB max Variable bounding The upper bound of timing variables are calculated by: = + ' s i , ', ' UB UB s S s L ' s s s i N ' s

Specified bound Lower bound of total changeover costs We specify a lower bound of the total sequence-dependent changeover costs in the objective function by the underlying cost structure. The lower bound of the total changeover costs is calculated by: = s i s min j i , \ , mc F s S AC i N , i j s = s s s i s i max i N F z BestC mc mc , , i j k ij s s S AC i N j N k T s S AC i N \ \ s s s s

Reformulation Linearization of nonlinear constraints The nonlinear constraints are linearized by the method in (Glover, 1975), s = s Let , then the following constraints are obtained: , ,, s k i , , ' tf y s AC k T i N , i k s ac k ' tf s = s ,, i k , ' I s i AC i s AC k T s s 0 , i k s UB y , , , s k i i k s s s (1 ) tf UB y , , , s k i i k s k s s tf , i k k Glover, F., 1975. Improved Linear Integer Programming Formulations of Nonlinear Integer Problems. Manage. Sci. 22, 455 460. doi:10.1287/mnsc.22.4.455

Reformulation Hull reformulation of GDP constraints s k A B C D E F + + + = + + , , , tb tb tb tb tb tb tb s AC k T tp TP , , s k tp , , s k tp , , s k tp , , s k tp , , s k tp , , s k tp s s A B C D E F + + + = + + , , , tf tf tf tf tf tf tf s AC k T tp TP s , , s k tp , , s k tp , , s k tp , , s k tp , , s k tp , , s k tp k A L tp U tp , ,, s k tp , , cp a tb cp a s AC k T tp TP , , s k tp , , s k tp s A L tp U tp , , , cp a tf cp a s AC k T tp TP , , s k tp , , s k tp s , , s k tp F U tp , ,, s k tp , , cp f tb UB f s AC k T tp TP , , s k tp , , s k tp s s F U tp , , , cp f tf UB f s AC k T tp TP , , s k tp , , s k tp s s , , s k tp + + + + + = , , , a b c d e f s k r s AC k T tp TP , , s k tp , , s k tp , , s k tp , , s k tp , , s k tp , , s k tp , s B C , , s k tp T = + ) ( + s k cp L tp U tp ( ) sd a tf cp , , s k tp b AC k cp c tb , , s k tp , , s k tp , , s k tp TP , , s k tp d + U tp L tp ( ) , , , cp s T tp , , s k tp s

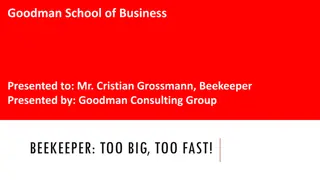

Computational Results Computational statistics of 8 instances Coil number Model size Integrality gap (%) Cost Instance Period CPUs * (103CNY) Discrete variable Continuous variable C1 C2 C3 C4 C5 Constraints 0.91 0.91 1 10 7 4 6 5 4 860 1,944 1,716 114.14 10.80 1.66 1.39 2 10 7 4 6 5 7 970 2,289 2,151 112.80 9.74 5.51 4.98 3 15 10 10 10 5 4 3,163 5,440 3,381 116.46 4.46 31.33 20.72 4 15 10 10 10 5 7 3,307 5,899 3,960 118.11 5.79 66.75 15.98 5 20 15 15 13 6 4 9,132 13,350 5,984 157.28 5.57 50.72 46.44 6 20 15 15 13 6 7 9,312 13,923 6,707 158.78 6.50 1511.28 1181.98 7 25 20 20 20 10 4 24,484 32,277 10,766 210.18 10.97 6172.25 1983.33 8 25 20 20 20 10 7 24,736 33,078 11,777 208.52 10.70 *: CPU seconds for 10-4and 10-2optimality tolerance, respectively.

Computational Results Gantt chart of the optimal solution of Instance 2

Remarks Integrated scheduling of multi-stage production in rolling sector of steel production Schedule optimizes coordination of production and electricity consumption. Novel continuous time mixed-integer linear programming model. Numerical experiments demonstrate effectiveness and tightness of the model.