Our LOTO Safety Culture Incident Analysis

The incident at SLAC revealed failures in following LOTO procedures, leading to multiple related incidents since early May. The safety pause issued by Steve Hoey mandates a Hazardous Energy Control Restart Process. The shocking event resulted from assumptions, lack of awareness, and inadequate PPE. Various reasons contributed to the incidents, highlighting issues with system changes, supervision, and procedure deviations. Lessons include addressing task demands, staffing levels, and clarifying expectations to prevent future incidents.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

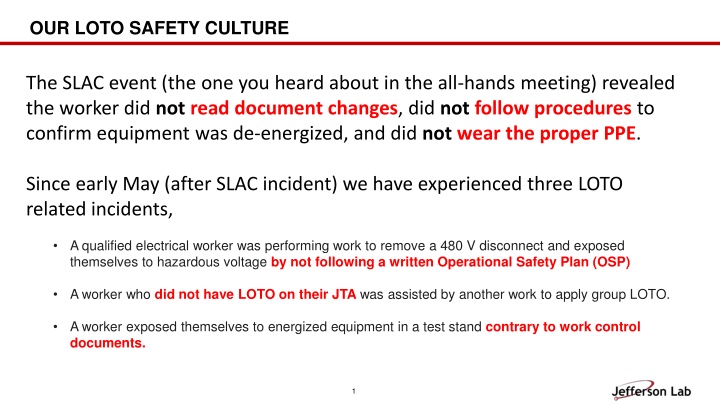

OUR LOTO SAFETY CULTURE The SLAC event (the one you heard about in the all-hands meeting) revealed the worker did notread document changes, did notfollow procedures to confirm equipment was de-energized, and did notwear the proper PPE. Since early May (after SLAC incident) we have experienced three LOTO related incidents, A qualified electrical worker was performing work to remove a 480 V disconnect and exposed themselves to hazardous voltage by not following a written Operational Safety Plan (OSP) A worker who did not have LOTO on their JTA was assisted by another work to apply group LOTO. A worker exposed themselves to energized equipment in a test stand contrary to work control documents. 1

LOTO SAFETY PAUSE Steve Hoey issued safety pause on LOTO, which remains in effect: In order to restart work in your area, you are required to follow The Hazardous Energy Control Restart Process. Within this process, you are required to download and print the HEC Restart Checklist You are also required to log your restart activity in an on-line electronic spreadsheet 2

SLAC SHOCK EVENT WHATHAPPENED? During a maintenance activity, a SLAC electrician made hand contact with a bare energized (live) circuit part inside an electrical cabinet Work activities should have resulted in the de-energization of this system, but did not The worker sustained severe injuries to the hands and face 3

HOW DID IT HAPPEN? The worker assumed he understood how the cabinet was powered, but this had been changed and he was not aware nor did he read the procedure which reflected this change The worker did not confirm the equipment had been de-energized per the procedure and training The worker was not wearing the correct PPE (not causal but contributed to the severity) 4

WHY DID IT HAPPEN? (2) Previous assessment findings were not quickly corrected (4) Ineffective supervisor oversight did not correct these problems (1) Lab allowed temporary system changes to become permanent without providing resources to document and communicate changes (3) Procedure deviation was normalized over time (skill vs rule) 5

WHAT CAN WE LEARN? Task Demands / Time pressure ( mission critical equipment going down) Less than optimal staffing levels issue was raised and a work around developed Lack of or unclear expectations - What is a good pre-job? Do we have a good procedure? Are we following the procedure? Changes/departures from routine the system did not respond as expected Unexpected equipment conditions the system did not react as expected but they convinced themselves it was ok Inaccurate risk perception workers had done this in the past with no severe outcomes 6