Overview of Cement Industry: Processes and Classification

The lecture from the Chemical Engineering Department at the University of Diyala delves into the chemical process industries, focusing on the Cement Industry. It covers the properties of cement, raw materials required, the process of making concrete using Portland cement, and the classification of various types of cement such as Portland cement, rapid-hardening cement, quick-setting cement, low-heat cement, and blast furnace cement. The lecture provides insights into the significance of cement in construction and the specific characteristics of each type.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Chemical Process Industries University of Diyala Chemical Engineering Department Lecture (7) .

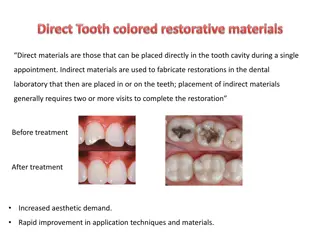

Cement Industry Cement: is a material with adhesive and cohesive properties which make it capable of bonding minerals fragments into a compact whole. For constructional purposes, the meaning of the term "cement" is restricted to the bonding materials used with stones, sand, bricks, building stones, etc

Raw material: 1) primary : which form > 85% clinker. 2) secondary: which form < 15% clinker. This is required to modify Si, Fe, Al %. 3) tertiary: are used for some purpose other than clinker formation , e.g. a) for reducing water content of slurry. b) increasing output of grinding equipment or decreasing power. c) output yield. d) fluxes for facilitating clinker production.

Concrete is made by portland cement, water and aggregates. Portland cement is a hydraulic cement that hardens in water to form a water- resistant compound. The hydration products act as binder to hold the aggregates together to form concrete

Classification of Cement : Classification of Cement : 1) Normal setting or ordinary cement- called Portland cement. 2) Rapid-hardening cement: this is a high early-strength (H.E.S) cement, the (H.E.S) is due to: a) finer grinding b) burning at higher temperature, and c) increased lime content in the composition.

3)Quick setting cement: the setting action starts within 5 min after addition of water and become stane hard in less than 0.5 hr. 4) Low heat cement: the heat of hydration is reduced . It cotain less lime than ordinary cement. 5) Blast furnace cement: 65% of blast furnace slag ( waste product, contain Al2O3& SiO2& CaO) is mixed with 35% clinker to make very strong and durable cement. .

Comparison between wet and dry process: