Ozone Layer and Laser Technology in Garment Industry

Learn about the significance of the ozone layer in shielding against ultraviolet radiation and the application of laser technology in the garment industry. Explore the advantages and disadvantages of laser fading and the general features of laser technology compared to manual processes.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

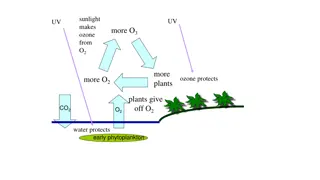

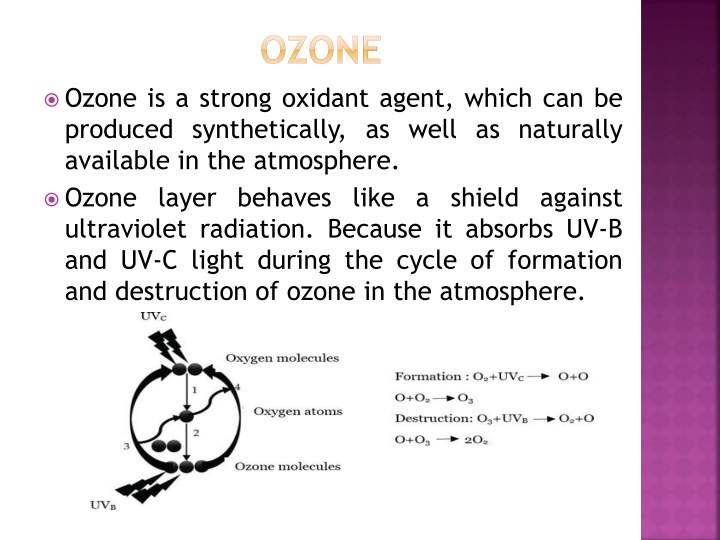

OZONE Ozone is a strong oxidant agent, which can be produced synthetically, as well as naturally available in the atmosphere. Ozone layer behaves like a shield against ultraviolet radiation. Because it absorbs UV-B and UV-C light during the cycle of formation and destruction of ozone in the atmosphere.

OZONE FADING OZONE FADING

WORK SEQUENCE Create design pattern: Creation of a design pattern and development of pattern from captured photo or design made by computer software. Convert into, bmp format: Conversion into grey scale .bmp format (bitmap image format). Input the design into Laser system: Putting the design file into the computer attached with laser m/c Set the pixel time: Set the luminance of light that will placed on the garments. Placing the garments: Placing the garments on honey comb table Location identification: Marketing a red light on the garments where laser light fall to make sure garments in placed properly. Start: run the m/c.

Disadvantages of laser fading: Initial investment is very high. Skilled operator is needed. Producing natural effect is difficult and often requires some manual touch. The laser beam itself and the produced fumes are health hazardous. Maintenance and servicing of the laser system may be troublesome in some cases.

SOME GENERAL FEATURES Effect quality finer than manual. Hand feel finer than manual. Less hairiness. Higher production cost Less working space Design consistency higher Higher tearing strength (vary in stretch denim) Rejection rate 0% (5% in Manual) Less manpower [Laser: Manual= 1:3 (Approx)] Higher power requirement (approx. 7.5 KWH) Harmful laser beam (if contact to skin or eyes)

VIDEO: SUSTAINABLE WASH (LASER AOP+OZONE)