Parameters for Network Sizing in Water Supply Systems

Essential parameters for sizing water supply networks include design period, water demand, consumption rate, pressure head, pipe sizes, and reliability considerations. Calculation methods and examples for determining design period, water demand estimation, peak factors, and reliability aspects are discussed. Tags: Water Supply, Network Sizing, Design Period, Water Demand, Pipe Material, Reliability

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

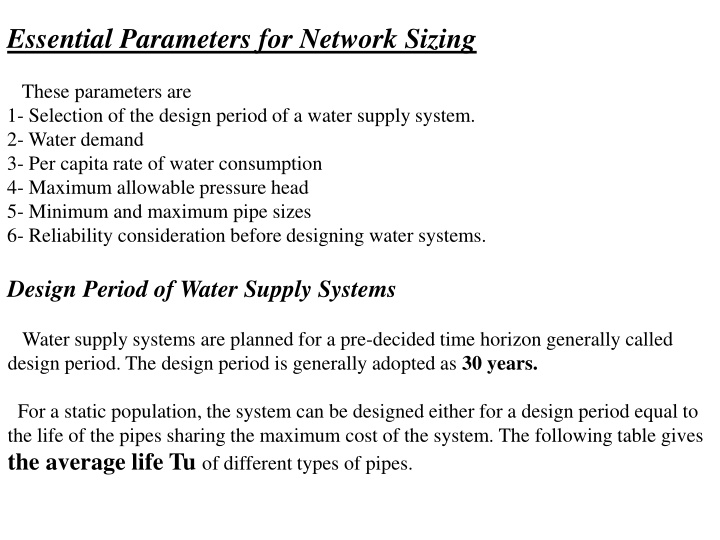

Essential Parameters for Network Sizing These parameters are 1- Selection of the design period of a water supply system. 2- Water demand 3- Per capita rate of water consumption 4- Maximum allowable pressure head 5- Minimum and maximum pipe sizes 6- Reliability consideration before designing water systems. Design Period of Water Supply Systems Water supply systems are planned for a pre-decided time horizon generally called design period. The design period is generally adopted as 30 years. For a static population, the system can be designed either for a design period equal to the life of the pipes sharing the maximum cost of the system. The following table gives the average life Tu of different types of pipes.

Pipe Material Life, Tu, Years Cast Iron(CI) 120 Galvanized Iron(GI) 120 Electric Resistance Welded(ERW) 120 Asbestos Cement(AC) 60 Poly(Vinyl chloride)(PVC) 60 Sharma and Swamee(2004) gave the following equation for the design period T of gravity flow systems: ? = ??(? + ?? ? ???) ?.??? And the design period for pumping system as: ? = ??(? + ?.??? ? ????+ ?.?? ?? ???) ?.? r = discount rate factor ?= rate of increase in water demand such that the initial water demand Qo increases to Q after time t as ? = ?????

Example Estimate the design period for a PVC water supply gravity as well as pumping main consider ? = 0.04/year and r = 0.05. ? = ??(? + ?? ? ???) ?.??? ? = 60(1 + 2 0.04 0.05 602) 0.375= 21.5 ????? = 21 years. ? = ??(? + ?.??? ? ????+ ?.?? ?? ???) ?.? ? = 60(1 + 0.417 0.04 0.05 602+ 0.01 0.042 602) 0.5 T = 29.77 years T = 30 years. Water Demand The estimation of water demand for the sizing of water supply system are: 1 Water demand from residential is approximately (400-450) l/c/d 2 Water demand from industrial and commercial development for industrial is about 121 l/c/d for commercial is about 80 l/c/d 3 Fire fighting demand using the following Eq. ?????? ??? ? = 1020 ? 1 0.01 ? , 4 Losses are approximated 83 l/c/d

Peak Factor The water demand is not constant throughout the day and varies greatly over the day. Generally, the demand lowest during the night and highest during morning or evening hours of the day. Water Services Association Australia (WSAA) , 2002 suggested the following peak factors for water supply system as Peak day demand = Average day demand ???? ??? ?????? Peak hour demand = Average hour demand ???? ??? ?????? The peak day factor and peak hour factor are listed below: peak day factor 1.5 for population over 10,000 2.0 for population below 2000 peak hour factor 2.0 for population over 10,000 5.0 for population below 2000 Reliability consideration The reliability consideration of water supply system can be divided into structural and functional forms. The structural reliability is associated with pipe, pump, and other components probability of failure and the functional reliability is associated with meeting nodal pressure and flow requirements.

Example: Calculate the required discharge for pumping station for the design of a water distribution system having a design population of 20000 Solution: 1 Water demand for residential 1000= 8500 ??? 2 Water demand for industrial and commercial Q2 for commercial= 20000 80 3 Fire fighting ? = ???? ? ? ?.?? ? ?3 = ? = 1020 20 1 0.01 20 Q3=4357.6 g/min = 23757 ?3 Q4 = 20000 83 1000= 1660 Qt = Q1 + Q2 + Q3 + Q4 Qt = 37937 ?3 Design discharge= 1.5 37937 = 56905.5 ?3/??? = 0.66 ?3/? Q1= 20000 425 ?3 Q2 for industrial = 20000 121 ?3 ??? 1000= 2420 ?3 ??? 1000= 1600 ??? ?3 ??? 4- Losses ???