pH Correction and Conditioning in Water Treatment - Overview and Key Points

Learn about the importance of pH correction and conditioning in water treatment to prevent corrosion of metals in Scottish waters. Discover the effects of low pH on metal fittings, possible sources of metals, and solutions like neutralizing filters and alkali dosing. Ensure proper maintenance and monitoring for effective pH correction and water safety.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Treatment pH Correction / Conditioning Matt Bower DWQR Risk Assessment Training 2018

Overview Many Scottish waters have low pH & alkalinity This makes water corrosive to metals, concrete If lead pipes will make problem worse Need to increase pH / alkalinity artificially Simple filters available Consider pH / alkalinity when investigating metal fails

Overview Image result for corroded lead Image result for corroded pipe Image result for green hair Image result for corroded lead Image result for boiler element corrosion

Overview Effects Metal Possible Sources Lead piping and tanks; solder; some brass fittings; stabiliser in some PVC pipes Plumbing fittings made from metal alloys, stainless steel and plated products Developmental issues in children; raised blood pressure in older people. Lead Chronic exposure may cause heart and liver damage. Dermatitis in those sensitised. Nickel Piping, brass fittings and fixtures. Taste, discolouration of fittings and hair, possibly gastro-intestinal effects. Toxic to people with Wilson s disease. Copper Galvanised piping and tanks, brass fittings Taste and potential gastro-intestinal effects at high concentrations. Zinc Iron or steel piping or tanks Primarily aesthetic sediment and brown discolouration. Substrate for accumulating contaminants from upstream sources. Iron

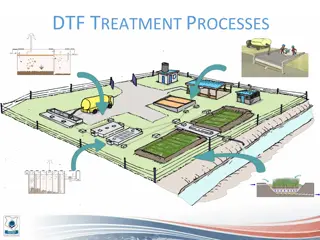

Usage on small water supplies Neutralising Filters Often upflow Media: Limestone Magnesium Oxide Dolomite Need to get reaction time right! Media will gradually be used up replace! Alkali dosing Sodium hydroxide COSHH issues Does not raise alkalinity only pH water could be >pH6.5 and still corrosive

Key Points to Watch For Evidence of excessive corrosion Is water clean enough for neutralising filter? Is contact time / media appropriate? Refer to mfrs spec. Is there a maintenance plan (topping up)? Is location of pH correction relative to disinfection appropriate? Suitable disinfection process needed downstream

Questions Many natural waters in the North and West of the UK are naturally of low pH. Consequently, many private water supplies require pH correction to ensure that the water is not corrosive to metal plumbing fittings. Care needs to be taken to ensure that any pH correction process is tightly controlled, as over- or under-correction can occur. Is there a risk of water supplied being of incorrect pH? 5 TPH1 Is there a risk or evidence of corrosion of fittings? This may be evident through staining of sanitary ware (often green if copper is present) and by an increased rate of leakage. 5 TPH2 Any pH correction treatment should be designed to deal with the quality of the incoming water at all operating flow rates. Although pH itself is usually fairly consistent, rapidly changing flows can be an issue and pH correcting filters can block if incoming water is not of the correct quality. Is there a risk of any installed pH correction failing or being inadequate? 4 TPH3 A pH correction plant will only perform effectively if it is correctly designed and operated in accordance with the initial specification. These should be documented to ensure requirements are clear. On-going maintenance will be required to ensure performance continues to be optimal. Is the plant inadequately maintained according to the design specification? 4 TPH4 Is there a risk of inadequate pH correction due to the lack of a programme in place to monitor and replace media on exhaustion? Many pH correction processes rely on contact with an alkaline media that is gradually used up. It will need periodic topping up with fresh media, however, this may significantly raise the performance of the filter to the point that over-correction is possible. Where only a proportion of the flow is treated, the blend may need to be adjusted to compensate. Regular monitoring of pH is essential. 4 TPH5 Raising the pH of the water may cause certain dissolved minerals (especially iron and manganese) to precipitate out, which can lead to the gradual clogging of the filter. If this is an issue, measures may be needed to periodically remove deposits from the filter. Is precipitate build up an issue (is it monitored / controlled)? 4 TPH6