Prediction of Al-alloy Hot Extrudate Deformation

This project aims to develop an accurate elasto-viscoplastic constitutive model for Al-alloy heat sink extrusion to predict and minimize warpage deformation, enhancing production efficiency and cost-effectiveness in thermal management applications.

Uploaded on | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

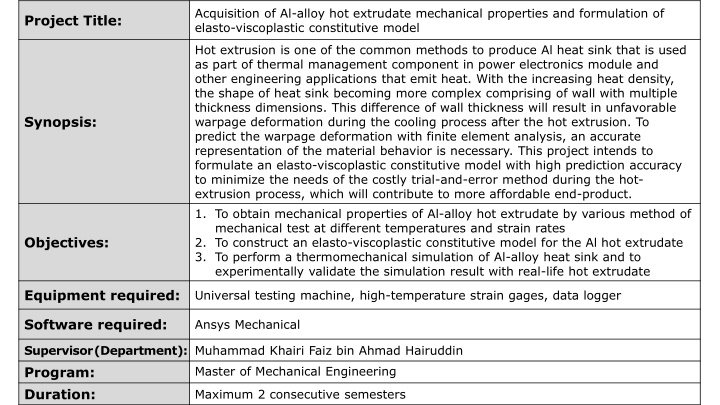

Acquisition of Al-alloy hot extrudate mechanical properties and formulation of elasto-viscoplastic constitutive model Project Title: Hot extrusion is one of the common methods to produce Al heat sink that is used as part of thermal management component in power electronics module and other engineering applications that emit heat. With the increasing heat density, the shape of heat sink becoming more complex comprising of wall with multiple thickness dimensions. This difference of wall thickness will result in unfavorable warpage deformation during the cooling process after the hot extrusion. To predict the warpage deformation with finite element analysis, an accurate representation of the material behavior is necessary. This project intends to formulate an elasto-viscoplastic constitutive model with high prediction accuracy to minimize the needs of the costly trial-and-error method during the hot- extrusion process, which will contribute to more affordable end-product. 1. To obtain mechanical properties of Al-alloy hot extrudate by various method of mechanical test at different temperatures and strain rates 2. To construct an elasto-viscoplastic constitutive model for the Al hot extrudate 3. To perform a thermomechanical simulation of Al-alloy heat sink and to experimentally validate the simulation result with real-life hot extrudate Synopsis: Objectives: Equipment required: Universal testing machine, high-temperature strain gages, data logger Software required: Ansys Mechanical Supervisor(Department): Muhammad Khairi Faiz bin Ahmad Hairuddin Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Project Title: Constitutive modelling of interconnect materials in power electronics module Reliability assessment of interconnect materials used in the power electronics module typically involve time and cost-consuming traditional experimental-based testing. To cut down the cost and production lead time, finite element analysis has been extensively adopted in the relevant industry. This project will focus on the modeling of elasto- viscoplastic constitutive equation of sintered metal nanoparticles or conventional Sn-based solder. Student is expected to review the existing mechanical properties of any interconnect materials and develop an elasto-viscoplastic model. A simple high- temperature tensile test will be performed to validate the constructed constitutive model. Depending on the nature of the constitutive equation, student might need to write a user- subroutine to be applied in the commercial finite element software. 1. To obtain mechanical properties of Sn-based solder interconnect at different temperatures and strain rates 2. To construct an elasto-viscoplastic constitutive model 3. To experimentally validate the proposed constitutive model with high- temperature tensile test finite element analysis Synopsis: Objectives: Equipment required: Universal testing machine, high-temperature strain gages, data logger Software required: Ansys Mechanical Supervisor(Department): Muhammad Khairi Faiz bin Ahmad Hairuddin Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Acquisition of mechanical properties of sintered copper nanoparticles for power electronics module application using the digital image correlation technique Project Title: Copper (Cu) nanoparticles sintering is expected to replace silver sintering as an interconnect materials in the power electronics module for electric vehicle application owing to its low cost. In order to assess the reliability of the sintered Cu nanoparticles by finite element method, a constitutive model is necessary. This project focuses on the acquisition of the mechanical properties of the sintered Cu nanoparticles in order to formulate the constitutive model. Sample will be subjected to shear mode tensile tests using the universal testing machine and digital image correlation method will be employed to obtain the strain data. Microstructure analysis will also be carried out to correlate the microstructural change with the mechanical properties. 1. To obtain mechanical properties of sintered Cu nanoparticles interconnect at different temperatures and strain rates via digital image correlation method 2. To construct an elasto-viscoplastic constitutive model 3. To experimentally validate the proposed constitutive model with high- temperature tensile test finite element analysis Synopsis: Objectives: Equipment required: Universal testing machine, high-temperature strain gages, data logger Software required: Ansys Mechanical Supervisor(Department): Muhammad Khairi Faiz bin Ahmad Hairuddin Program: Master of Mechanical Engineering Duration: Maximum 2 consecutive semesters

Classification of high voltage cable joint defects using support vector machine and noise reduction on partial discharge signals Project Title: In this work, classification of high voltage cable joint defect types using support vector machine and noise reduction techniques on partial discharge signals will be performed. Four cross-linked polyethylene (XLPE) cable joints with artificially created defects will be prepared based on the defects commonly encountered on site. Different noise reduction techniques will be applied to denoise the PD signals. The denoised signals will be used as a feature for classification of defects in cable joints using support vector machine. The classification results will be compared between the proposed method and the existing works to evaluate the performance of the applied techniques. 1. To perform measurement of partial discharge (PD) on artificially-prepared cable joint defects 2. To apply support vector machine and various noise reduction methods on PD signals for classification of XLPE cable joint defects 3. To compare the classification results between the proposed method and the existing works Synopsis: Objectives: Equipment required: Software required: Partial discharge measurement setup, high voltage generation kit, cable joint MATLAB, partial discharge analysis software Supervisor(Department): Assoc. Prof. Ir. Dr. Hazlee Azil Illias (Electrical) Program: Master of Power System Engineering / Master of Engineering (Power System) Duration: Maximum 2 consecutive semesters