Price and Availability of Materials in Manufacturing

Long-term increase in raw material prices, short-term fluctuations due to market forces, use patterns in developed countries, materials mix, rate of consumption, resource base vs reserves, materials substitution & recycling. Explore the cost and energy content of various engineering materials, growth in consumption, substitution properties, and the importance of recycling to reduce material costs.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

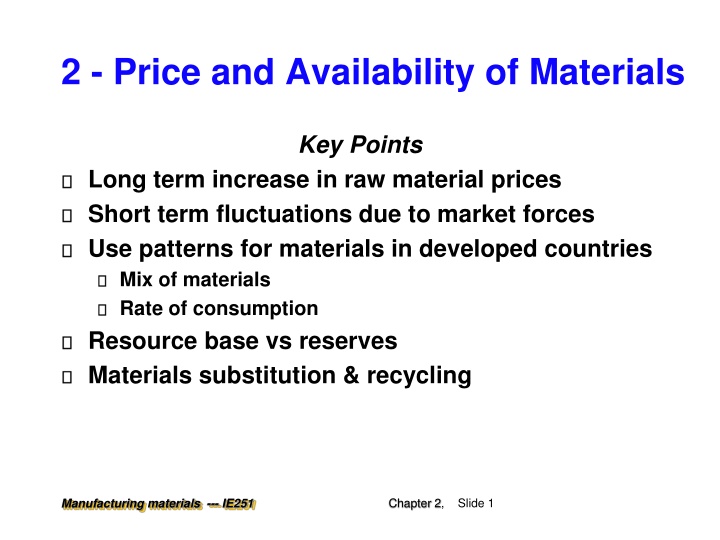

2 - Price and Availability of Materials Key Points Long term increase in raw material prices Short term fluctuations due to market forces Use patterns for materials in developed countries Mix of materials Rate of consumption Resource base vs reserves Materials substitution & recycling Chapter 2, Slide 1 Manufacturing materials --- IE251

Material $/ton 6-9 x 108 Diamonds 4.5 6.75 x 106 Gold 2 x 104 Material Costs (Table 2.1) Tungsten 7 9 x 104 Nickel Alloys Nylon 66 3750 - 8100 Alumina (fine ceramic) 12000 - 18000 Stainless steel 2700-3450 Aluminum alloys 1365 - 1800 Low alloy steel 480 - 675 Mild steel (bar, sheet, etc.) 375 - 525 Cement 75 - 90 Chapter 2, Slide 2 Manufacturing materials --- IE251

Elemental Abundance in Earths Crust Element % Silicon 27 Aluminum 8 Iron 5 Titanium 0.4 Manganese 0.1 Chapter 2, Slide 3 Manufacturing materials --- IE251

Production of Engineering Materials is Energy Intensive Material Energy Content (GJ/ton) Aluminum 280 Plastics 85-180 Copper 140 - 300 Steel 55 Cement 7 Timber 2.5-7 Chapter 2, Slide 4 Manufacturing materials --- IE251

Growth in Consumption Let our consumption be called C Assume that each year we consume r% more of a given material Fig. 2.2 Consumption r dC dt 100C = Co Time doubling-time, tD ~ 70/r Chapter 2, Slide 5 Manufacturing materials --- IE251

Substitution Properties, vs. the material itself New or alternative materials can replace scarce conventional materials Bridges: Stone & wood Plumbing: Copper Replacement may involves new costs Plant & equipment Processing & manufacturing methods Workforce training concrete & steel polyethylene Chapter 2, Slide 6 Manufacturing materials --- IE251

Recycling If energy costs, capital costs, or resource costs (e.g. through scarcity or depletion) are high, recycling can be an effective method for reducing material costs Labor intensive Requires design for recycling May involve its own capital and training costs Chapter 2, Slide 7 Manufacturing materials --- IE251

Materials and Energy in Car Design Key Concepts Stiffness and Yield-Limited Materials Selection Other Materials Selection Issues Chapter 2, Slide 8 Manufacturing materials --- IE251

Materials in Car Design Chapter 2, Slide 9 Manufacturing materials --- IE251

Energy to Manufacture and Use Cars (per Year) Energy to Produce Cars 0.8-1.5% of Total Energy Consumed by Nation Energy to Move Cars 15% of Total Energy Consumed by Nation Total Energy to Transport People and Goods 24% of Total Energy Consumed by Nation Chapter 2, Slide 10 Manufacturing materials --- IE251

How Can We Reduce the Energy Needed to Move Cars? Goal: Production prototype" by 2004 of a full sized car that will get three times the mileage of today's models (80 mpg) with no sacrifice in safety, performance, affordability or compliance with emission standards. How can you do this? Improve engine efficiency Reduce the weight of the car Chapter 2, Slide 11 Manufacturing materials --- IE251

Comparison Steel Vs SMC $0.35/lb 0.03 thick 7.6 lb 40% scrap $4.25 mat l cost 400/hr 5 workers $18.90/hr (Union) $0.24 labor cost $5,000,000 equipment $900,000 tools $7.71 unit cost at 100,000 units $0.65/lb 0.12 thick 7.0 lb 6% scrap $4.84 mat l cost 40/hr $12.50/hr (non-Union) $0.63 labor cost $1,200,000 eqipment $250,000 tools $7.75 unit cost at 100,000 units Chapter 2, Slide 12 Manufacturing materials --- IE251

Vehicle Weight is Important! Chapter 2, Slide 13 Manufacturing materials --- IE251

Automotive Materials Current vehicles consist primarily of iron and steel ~255 lbs. Aluminum (2001 Vehicles) ~253 lbs. Plastics (2001 Vehicles) Candidate alternative materials High strength steel (>120 lbs) Aluminum (600 lbs) Glass fiber reinforced polymers (150 lbs) Magnesium, Titanium, MMC s Chapter 2, Slide 14 Manufacturing materials --- IE251

Weight Reduction Targets--PNGV Subsystem Current Wt (lbs) 1134 Target Wt (lbs) 566 Reduction (%) 50 Body Chassis 1101 550 50 Power Train 868 781 10 Fuel/Other 137 63 55 Curb Weight 3240 1960 40 Chapter 2, Slide 15 Manufacturing materials --- IE251

Candidate Materials for Car Bodies Chapter 2, Slide 16 Manufacturing materials --- IE251

Automotive Materials Service Requirements Chapter 2, Slide 17 Manufacturing materials --- IE251

Other Properties of Body-Panel Materials Chapter 2, Slide 18 Manufacturing materials --- IE251

And what about PRICE! Most of the steel used for automotive applications costs well under $0.50 per pound, while most product forms of aluminum and magnesium cost more than $1 per pound and extremely lightweight titanium and carbon fiber are more than $8 per pound. Furthermore, manufacturing processes need to be improved or developed to fabricate lightweight parts and components of these materials affordably and quickly. A. Sherman PNGV Materials Technical Team Chapter 2, Slide 19 Manufacturing materials --- IE251

Conclusions Chapter 2, Slide 20 Manufacturing materials --- IE251