Principles of Building a Resilient Supply Chain for Business Continuity

Learn about the key elements and principles involved in designing a resilient supply chain to ensure business survival and thrive amidst uncertainties such as pandemics, geopolitical tensions, and natural disasters. Discover the importance of agility, collaboration, visibility, redundancy, flexibility, risk management strategies, and more to enhance supply chain resilience.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

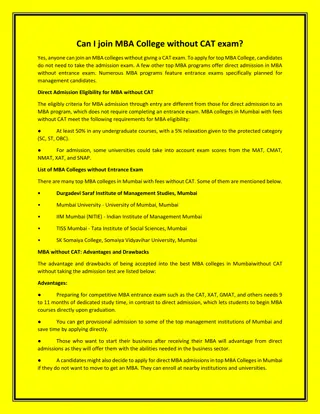

DESIGNING A RESILIENT SUPPLY CHAIN & ITS PRINCIPLES ARMAAN SALIK J

INTRODUCTION TO SUPPLY CHAIN RESILIENCE Definition of a Resilient Supply Chain:The ability of a supply chain to anticipate, prepare for, respond to, and recover from disruptions while maintaining continuous operations. Importance of Resilience: Helps businesses survive and thrive despite uncertainties. Reduces financial losses and operational delays. Improves customer trust and brand reputation. Examples of Recent Disruptions: COVID-19 Pandemic: Impact on global logistics, labor shortages, and supply-demand mismatches. Geopolitical Tensions: Trade wars, sanctions, and regional conflicts affecting supply chains. Natural Disasters: Earthquakes, hurricanes, and floods disrupting logistics and production.

KEY ELEMENTS OF A RESILIENT SUPPLY CHAIN Agility: Ability to respond quickly to unexpected changes. Collaboration: Real-time monitoring of demand fluctuations. Strong supplier relationships ensure mutual support during crises. Shorter lead times and adaptable production lines. Visibility: Strategic alliances with logistics providers and technology partners. End-to-end tracking of goods and raw materials. Sharing data and insights across the supply chain. Use of IoT sensors, AI, and blockchain to enhance transparency. Redundancy: Supplier and logistics network monitoring. Maintaining safety stock for critical components. Flexibility: Having backup production facilities and alternative logistics routes. Ability to switch suppliers, production locations, and transport modes. Investing in dual-sourcing strategies. Multi-sourcing strategies to avoid dependence on a single vendor. Dynamic inventory management.

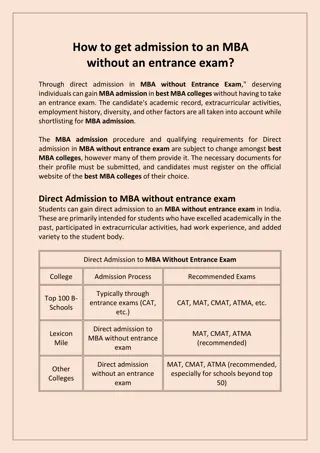

PRINCIPLES OF DESIGNING A RESILIENT SUPPLY CHAIN Risk Identification & Assessment: Inventory Optimization: Conducting regular risk assessments and supply chain audits. Balancing Just-in-Time (JIT) and buffer stock approaches. Using predictive analytics to anticipate disruptions. Mapping critical vulnerabilities across the network. Implementing smart warehousing solutions. Diversification: Creating contingency stock for critical items. Expanding supplier base to reduce dependency on specific regions. Sustainability & Compliance: Ensuring ethical sourcing and responsible production. Nearshoring and reshoring strategies for local production. Investing in multiple logistics providers. Meeting environmental, social, and governance (ESG) criteria. Digitization & Data Analytics: Adhering to international trade and regulatory standards. Implementing AI-driven demand forecasting. Using blockchain for secure and transparent transactions. Employing IoT for real-time tracking and monitoring.

RISK MANAGEMENT STRATEGIES Proactive vs. Reactive Strategies: Proactive: Predicting risks and implementing preventive measures. Reactive: Quick response plans to minimize damage when disruptions occur. Implementing Contingency Plans: Creating business continuity plans (BCPs). Establishing crisis response teams. Conducting Regular Stress Tests & Scenario Planning: Simulating potential disruptions to test readiness. Evaluating supply chain performance under different conditions. Insurance & Financial Risk Mitigation: Ensuring coverage for supply chain interruptions. Hedging currency fluctuations and commodity price risks.

TECHNOLOGY AND DIGITALIZATION IN SUPPLY CHAIN RESILIENCE IoT & AI: Predictive analytics for demand and supply fluctuations. Automated alert systems for potential disruptions. Blockchain: Enhancing traceability and accountability in transactions. Reducing fraud and counterfeit risks. Cloud-based Supply Chain Management (SCM) Software: Centralized data sharing and decision-making. Enabling real-time collaboration among stakeholders. Automation & Robotics: Smart warehouses using automated guided vehicles (AGVs). AI-driven robotics for manufacturing and logistics.

CASE STUDIES OF RESILIENT SUPPLY CHAINS Toyota s Just-in-Time Strategy & its Shift Post-2011 Earthquake: Before: Lean manufacturing with minimal inventory. After: Adoption of backup suppliers and increased safety stock for critical components. Amazon s Supply Chain Innovations: Investment in AI-driven forecasting and robotics. Diversification of fulfillment centers for rapid delivery. COVID-19 Response: Pharmaceutical & Food Supply Chain Adaptations: Increased local sourcing and nearshoring. Rapid digitalization to manage supply-demand mismatches.

CONCLUSION & FUTURE TRENDS Continuous improvement & adaptability in supply chain strategies. Importance of investing in resilient infrastructure and technologies. Future Trends: AI-driven supply chain automation. Sustainability and green supply chain initiatives. Regionalization and reshoring of critical manufacturing operations.