Project Quality Management Overview and Key Concepts

Explore project quality management including key concepts like customer satisfaction, continuous improvement, ISO standards, and PMI's approach. Understand quality terms, importance of precision and accuracy, and the Cost of Quality (COQ). Learn about managerial analysis, TQM, and the ISO 9000/9001 series. Discover the significance of prevention over inspection, quality planning, assurance, and control. Delve into how quality is defined by the customer and integrated into all aspects of an organization.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

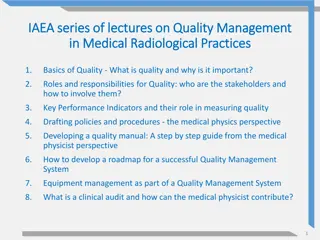

Project Quality Management 8.1 Plan Quality 8.2 Perform Quality Assurance 8.3 Perform Quality Control

Quality Terms Grade - Category or rank given to entities having the same functional use but different technical characteristics - Low QUALITY ALWAYS a problem! - Low GRADE may not be problem Quality requirements - Determining the required quality grade - Determining the required quality level Precision - Consistency that the value of repeated measurement are clustered Accuracy - Correctness that the measured value is very closed to the true value

Key Concepts Costumer satisfaction Prevention over inspection Quality is a management responsibility Quality is defined by the customer Quality is planned-in, not inspected-in Continuous improvement The cost of quality(COQ)

Key Concepts Managerial Analysis - Optimal quality is reached at the point where the incremental revenue from improvement equals the incremental cost to secure it Continuous Improvement (Kaizen) - Small improvement in products or processes to reduce costs and ensure consistency of products or services TQM - Philosophy that encourage organization and people to find ways to continuously improve their business practices - Quality relates to all aspects of an organization

ISO 9000/9001 Series A quality system standard applicable to any product, service, or process, in any industry Consists of a three-part continuous cycle - Planning - Controlling - Documentation Not a standard for products and services. Not industry specific.

Quality Management in Projects PMI s approach on quality management is compatible with ISO Standards. Project Manager s has done ultimate responsibility for quality management on the project. Gold Plating : Giving the customer more than they requested- extra functionality, higher quality, better performance. Implications is that you could have delivered what the customer expected faster and cheaper.

Project Quality Management Includes the process and activities of the performing organization the determine quality policies objectives and responsibilities, so that the project will satisfy the needs for the which it was undertaken *

Responsibility for Quality Project manager has the ultimate responsibility for the product of project Team members has responsibility to check his or her work(self-inspection) Senior management has the ultimate responsibility for quality within the organization as a whole Some costs of quality are too expensive for one project. Formal quality management must be implemented at an organization level.

Impact of Poor Quality Increased costs Low team moral Lower customer satisfaction Increased risk

8.1 Plan Quality Process Inputs Outputs Identifying quality requirements and/or standards for the project and product, and documenting how the project will demonstrate compliance . Scope Baseline Stakeholders Register Cost performance baseline Schedule Baseline Risk Register Enterprise environmental factors Organizational process assets Quality Management Plan Quality metrics Quality checklists Process Improvements Plan Project Document updates Stakeholders register Responsibility Assignment Matrix Tools & Techniques Cost Benefit Analysis Cost of quality (COQ) Control Charts Benchmarking Design of Experiments Statistical Sampling Flowcharts Proprietary quality management methodologies Additional quality planning tools

Output- Quality Management Plan Describe the system used by the Project management team to implement the quality policy on the project Provides input to the integrated project plan Based on the project scope and requirements Purpose is to prevent the occurrence of defects and reduce the cost of quality Must address quality assurance (QA), quality control (QC) and continuous process improvement

Other outputs Quality Metrics - Detailed description of what will be measured and how Quality Checklist - Tools are used to do verify that all required steps have been performed, usually component-specific. Process improvement plan - Details the steps for analysing process to identify activities which enhance the value. - Process boundaries - Process configuration - Process Metrics - Targets for improves to performance

Quality Planning Tools Cost benefit analysis - Considering benefits various the cost of satisfying quality requirement Cost of quality - Looking at how the cost of quality will impact the overall project cost Prevent phone cost Appraisal cost Failure cost

Cost of Quality Cost of Conformance Cost of Non Conformance Prevention Costs (Build a quality product) Training Documents Process Equipments Time to do it right Appraisal Costs (Assess the quality) Testing Destructive testing loss Inspections Internal Failure Costs (Failures found by the project) Rework Scrap External Failure Costs (Failures found by the customer) Liabilities Warranty work Lost business Money spent during and after the project because of failures Money spent during the project to avoid failures

Additional Quality Planning Tools Control Charts Used to determine whether a process is stable or has predictable performance Covered in more detail in Perform Quality Control Benchmarking Looking at past projects to identify areas of improvement and to provide a measure of quality performance.

Additional Quality Planning Tools Design of Experiments Systematic use of experimentation to determine what variables will improve quality Statistical sampling Inspect by choosing only part of a population When studying the entire population would take too long, measurement is destructive or too expensive. Proprietary quality management methodology Six sigma, CMMI, etc.

Additional Quality Planning Tools Flow Charting Graphical representation of how process flows from the beginning to end Used in quality planning to anticipate quality problems that might occur. Fishbone Diagram (Ishikawa) Graphical tool that shows how various elements of system or process (causes) affect the result (effect)

Fishbone diagrams examples Material Machines Bad Tuning Material damaged Incorrect Material Defects MAJOR DEFECT Wrong Techniques Poor Planning Poor Skills Bad Attitude Personnel Process

8.2 Perform Quality Assurance PROCESS Auditing the quality requirements and the results from quality control measurements to ensure appropriate quality standards and operational definitions are used OUTPUTS Organizational process assets updates Change requests Project management plan updates Quality management plan Schedule management plan Cost management Project document updates Quality audit reports Training plans Process documentation INPUTS Project Management Plans Quality Metrics Process Improvement Plan Work Performance Information Quality Control measurement TOOLS & TECHNIQUES Plan Quality and Perform Quality Control tools and techniques Quality audits Process analysis

Quality Audits A structured, planned review of quality management activities using the appropriate tools and techniques. Ensure work is being performed to quality standards Proactively offer assistance to improve implementation of process to assist team in raising productivity The objective is to identify lessons learned for improving performance May be performed by in-house auditors or by third party agencies.

8.3 Perform Quality Management OUTPUTS Quality control measurement Validated changes Validated deliverable Organization process assets updates Complicated checklist Lesson learned Change request Project management plan updates Quality management plan Process improvement plan PROCESS Monitoring & recording result of executing the qualities activities to assess performance & recommend necessary changes INPUTS Project management plan Quality matrices Quality checklist Work performance measurement Approved change request Deliverable Organizational process assets TOOLS & TECHENIQUE Cause & effect diagram Control chats Flowcharting Histogram Pareto chat Run chat Scatter diagram Statistical sampling

Deliverables Quality management addresses - Products, services or result of the project - Project management deliverable

Quality Control Tools Fishbone diagram - Cause and effect diagram (Ishikawa) Control chats - Shows if a process is stable or has predictable performance Flowcharting - Graphical representation of a process Histograms - Bar chart showing a distribution of variables Run chart - Examining history and pattern of a variation Technical performance Cost and schedule performance

Quality Control Tools Pareto chart - Ordered by frequency of occurrence, Identify problem with the greatest impact Statistical sampling Scatter diagram - Show the relationship between two variables - Identify the possible relationship between changes observed Inspection - Examination of a work product to determine whether it conform to standards Approved change request review - Ensuring all changes request are reviewed and implemented as approved

Control chart Specification Limit Rules of Seven Control Limits Out of Control Specification Limit Assignable Cause

Flowchart 1 2 3 Project Request Compliance Copy Develop Artwork No 4 Artwork Approved 7 6 5 Vendors Make proofs Artwork Out For proofs Change Control for Specs. No Yes No 10 8 Approved Proof Back to Vendor 9 Package development Review/ Approval Yes Yes QA Review/ Approval 12 11 Order Materials Specs Signed (Package and QA)

Histogram Depicts a distribution of cases that fall into categories Height of each bar represents the frequency of occurrence Provides an approximation of a data distribution

Run chart Displays data points observed in a time sequence Examines history and pattern of a variation - Technical performance - Cost and schedule performance Facilities analyzing how quality trends over time

Scatter Diagram Look for a pattern between the two variables. Confirm that there is a relationship between two variables. Linear patterns (i.e. points close to a diagonal line) indicate patterns.

Planning, Assurance & Control Quality Planning Quality Assurance Quality Control When is performed? Planning Executing Controlling Major concern Plan Implementing, Overall check, Process correctness Measure What quality standard should be used? How will these standard be met? How can the quality be improved? Are the standards still relevant? What is the number of errors? What is the schedule performance? Have we met the standards? Typical questions

Question ?