Quality by Design: Understanding the Importance and Benefits

"Quality by Design (QbD) is a systematic approach focusing on product and process understanding to ensure predefined quality standards. Learn about the definition, benefits, significance, approach, and key characteristics of QbD for various pharmaceutical applications."

Uploaded on | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

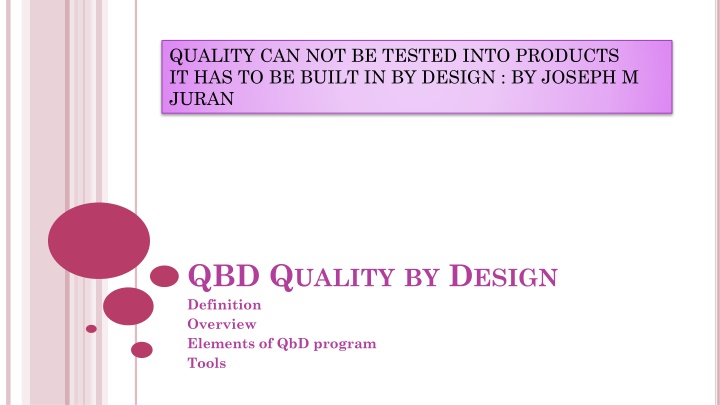

QUALITY CAN NOT BE TESTED INTO PRODUCTS IT HAS TO BE BUILT IN BY DESIGN : BY JOSEPH M JURAN QBD QUALITY BY DESIGN Definition Overview Elements of QbD program Tools

DEFINITION It is systematic approach to development, begins with predefined objectives, emphasizes on product and process understanding & process Control based on sound science and QRM (Quality risk mgt) 2

BENEFITSOF QBD Eliminate batch failures Minimize deviations and costly investigations Avoid regulatory compliance problems Empowerment of technical staff Increase manufacturing efficiency, reduce costs and project rejections and waste Build scientific knowledge base for all products Provide Better interaction with industry on science issues Ensures consistent information Incorporate risk management Reduce end-product testing 3

SIGNIFICANCEOF QBD Quality by Design means designing and developing formulations and manufacturing processes to ensure a predefined quality Quality by Design requires understanding how formulation and manufacturing process variables influence product quality . Quality by Design ensures Product quality with effective control strategy 4

QBD APPROACHCANBEUSEDFOR Active pharmaceutical Ingredients Materials including Excipients Analytics Simple dosage forms Advanced drug delivery systems Devices Combination products (e.g. theranostics- comb. Of using one radioactive drug & 2nd radioactive drg to treat main tumor) 5

KEYCHARACTERISTICSOF QBD A tool for focused & efficient drug development Provides Dynamic and systematic process Relies on the concept that Quality can be built in as a continuum It is applicable to Drug Product and Drug Substance development (chemicals / biologics) It is applicable to analytical methods Can be implemented partially or totally Can be used at any time in the life cycle of the Drug Always encouraged by Regulators. 6

KEYELEMENTSOF QBD ICH Q8: Pharmaceutical Development discusses the various elements of quality by design. These in combination with the enablers forms the fundamental basis for the QbD approach to development. It involves the following key elements during pharmaceutical development Quality Target Product Profile (QTPP) Identify the Quality Attributes Determine the Critical Quality Attributes Determine the Critical Material Attributes Link raw material attributes and process parameters to CQA s Identify a Control Strategy & Design Space Manage product lifecycle, including continuous improvement 7

WHATARETHESTEPS/ELEMENTS INA QUALITYBY DESIGN APPROACH? 1. Target product profile 2. Critical quality attributes 6. Risk Management 5. Establish control strategy 3. Link MA s & PP s to CQA s 8 4. Establish Design space

QUALITY TARGET PRODUCT PROFILE The target product profile (TPP) has been defined as a prospective and dynamic summary of the quality characteristics of a drug product that ideally will be achieved to ensure that the desired quality, and thus the safety and efficacy, of a drug product is realized . Considerations include Clinical setting, route of administration, dosage form, delivery systems Dosage strengths Container closure system Therapeutic moiety release or delivery & attributes affecting pharmacokinetic characteristics (dissolution) Drug product quality criteria (sterility, purity, stability, drug release) appropriate for intended marketed product 9

CRITICAL QUALITY ATTRIBUTES A CQA is a physical, chemical, biological, or microbiological property or characteristic that should be within an appropriate limit, range, or distribution to ensure the desired product quality. CQAs are generally associated with the Drug substance, Excipients, Intermediates (in-process materials) and Drug product. 10

MATERIALATTRIBUTE Material: Raw materials, starting materials, reagents, solvents, process aids, intermediates, API s, packaging and labelling materials, ICH Q7A Attribute: A physical, chemical, biological or microbiological property or characteristic Material attribute: Can be an excipient CQA, raw material CQA, starting material CQA, drug substance CQA etc A material attribute can be quantified Typically fixed can sometimes be changed during further processing (e.g. milling) Examples of material attributes: impurity profile, porosity, specific volume, moisture level, sterility. 11

PROCESS PARAMETER A process parameter whose variability has an impact on a critical quality attribute and therefore should be monitored or controlled to ensure the process produces the desired quality (Q8R2) CPPs have a direct impact on the CQAs A process parameter (PP) can be measured and controlled (adjusted) Examples of CPPs for small molecule: Temperature, addition rate, cooling rate, rotation speed Examples of CPPs for large molecule: Temperature, pH, Agitation, Dissolved oxygen, Medium constituents, Feed type and rate 12

DESIGN SPACE Definition The multidimensional combination and interaction of input variables (e.g., material attributes) and process parameters that have been demonstrated to provide assurance of quality Regulatory flexibility Working within the design space is not considered a change Important to note Design space is proposed by the applicant and is subject to regulatory assessment and approval 13

DESIGN SPACE DETERMINATION First-principles approach Combination of experimental data and mechanistic knowledge of chemistry, physics, and engineering to model and predict performance Non-mechanistic/empirical approach statistically designed experiments (DOE s) linear and multiple-linear regression Scale-up correlations Translate operating conditions between different scales or pieces of equipment Risk analysis Determine significance of effects any combination of the above 14

CONTROL STRATEGY A planned set of controls Derived from current product and process understanding That assures process performance and product quality. The controls can include Parameters and attributes related to Drug substance Drug product materials Components, facility equipment operating conditions In-process controls Finished product specifications, and The associated methods and frequency of monitoring and control (ICH10) 15

TOOLS: DOE Design of experiments: Method: Choose experimental design (full factorial, optimal) Conduct randomized experiments Analyze data Create multidimensional surface model DOE Creates relationship between input and output How factors jointly affect the output responses Maximizing gain and minimizing resources Material attributes like particle size of raw material or excipients and process parameters (speed of press. Spray rate) Critical quality attributes in process or materials or final drug product eg. Blend uniformity, particle size particle size distribution of granules, tablet assay, content uniformity, drug release etc. DOE helps in identification of optimum conditions, CMA, CPP, Design space16

RISK ASSESSMENT Risk : Risk is defined as the combination of the probability of occurrence of harm and the severity of that harm. Risk Assessment A systematic process of organizing information to support a risk decision to be made within a risk management process. It consists of the identification of hazards and the analysis and evaluation of risks associated with exposure to those hazards. 17

PAT (PROCESSANALYTICALTECHNOLOGY) System to design, analyze, control manufacturing through timely measurements during processing of critical quality and performance attributes of raw material and process materials to ensure final product quality Includes chemical, physical, microbiological, mathematical, risk analysis Can be part of control strategy Provides continuous monitoring of CPPs, CMAs, CQAs Ex: PAT Tablet Production Compression functional tests (chemical/physical) Validate process control Control blending (particle size, disintegrant distribution) Process focused Risk predictive models 18

CONCLUSION Quality by Design define target product quality profile ,design and develop formulation and process to meet target product quality profile, Identify critical raw material attributes, process parameters, and sources of variability. PAT (Process analytical Tech), DoE, and risk assessment are tools to facilitate the implementation of QbD. There is a need for vigorous and well funded research programs to develop new pharmaceutical manufacturing platforms. 19