Raw water intake

Water intake systems play a critical role in various applications. This content delves into the most common types of water intake structures, factors influencing intake site selection, and the importance of screening mechanisms such as fine screens and microstrainers. Additionally, it discusses the concept of hydraulic losses in bar racks and offers insights into the design considerations of these components in water intake systems.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

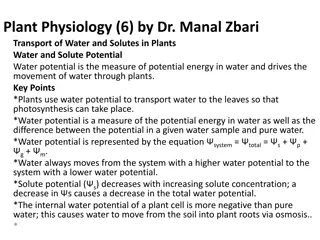

The most common type are: 1. The floating intake. 2. Submerged intake. 3. Tower intake.

Intake site selection 1. Water quality 2. Water depth 3. Stream velocity 4. Proximity to water treatment plant 5. Environmental impact. 6. Hazard to navigation.

Screening : Screening as a unit that removes suspended matter from water. screen may be classified as coarse and fine screen. Coarse screen Consist of vertical bars spaced with 5 8 CM of clear opening.

Fine screen Fine screen are used to remove samller objects that may damage pumps or other equipments. Screen with small opening will retain large quality of material, therefore they may require automatic cleaning.

Microstrainer Microstrainser is are used for the removal of plankton and algae from imounded water

BAR RACKS Hydraulic Loss hL = 1 12 - v2 0.7 2g hL = head loss 0.7 = An empirical discharge coefficient to account for turbulence and eddy losses.

v = velocity of flow through the opening of the bar racks v1 = proposed velocity in the upstream channel g = accelaration due to gravity, (m/s2)

Fine Screen hL = 1 Q 2 C (2g) A Q = discharge through screen A = effective open area of submerged screen, m2 C = coefficient of discharge for the screen ( typical,C = 0.84)

Fine Screen hL = 1 Q 2 C (2g) A Q = discharge through screen A = effective open area of submerged screen, m2 C = coefficient of discharge for the screen ( typical,C = 0.84) 14 of 11

Intake Works Most grit chambers are designed to capture particles of 0.2mm diameter and specific gravity of 2.65 The usual design parameter are a surface loading rate, Q/A of 100m3/h/m2 at maximum flow and downstream velocity of 0.3m/s. Range of surface rate 27m3/h/m2 to 100m3/h/m2 Retention time is 90 seconds

DESIGN OF INTAKE WORKS Treatment Plant Capacity = 80 MLD Inplant Used (Provide) = 6% In flow = 80 x 1.06 = 84.8 MLD = 3,533 m3/h

SIZING OF INTAKE Design Criteria, Surface Load, Vs = 50 m3/h/m2 ( Design Range 27-100 m3/h/m2 ) Area Required A = Q Vs = 3,533 m3/h 50 m3/h/m2 = 70.66 m2

SIZING OF INTAKE Provide 2 Channels Area per channel = 70.66 m2 2 = 35.33 m2 Consider L : B ratio of 4 : 1 4B2 = 35.33m2 B = 2.97m

THE SIZE OF THE INTAKE WORKS 6.99 2.97 2.97 350 12.58 m 11.88 m 350 350 350 350

B B 500 HWL NLL LWL 0.66m

HWL NWL LWL 0.66m River load 1m

PROPOSED APPROACHING VELOCITY = 0.3 m/s Q = Av A = 3533 m3/h 2 channels x 0.3 m/s = 1.63m2 PROPOSED WIDTH = 2.97 m Water depth, d = 1.63 2.97 d = 0.55m

CONSIDERING 20% OF SILTATION d1 = 0.66 m Depth below the L.W.L, d1 = 0.66 m

OTHER FACILITIES AT INTAKE 1. LIFTING FRAME FOR PUMPS 2. SAND INJECTORS SYSTEM FOR SAND REMOVAL 3. SURGE SUSPRESSION SYSTEM 4. ACCESS LADDERS 5. ELECTRICAL SWITCH BOARD

6. ELECTRICAL SUBSTATION (if required) 7. LIFTING FACILITIES FOR FINE SCREEN (manual) 8. PARAMETER FENCING WITH ENTRANCE GATE 9. COMPOUND LIGHTING 10. ACCESS ROAD 11. CCTV, SCADA AND TELEMETRY SYSTEM 12. SECURITY GUARD HOUSE