Reclaimers' Insight into Carpet Recycling Value and Market Dynamics

Gain valuable insights into the factors influencing the value and costs in carpet recycling, focusing on polymer types, purity, properties, and market considerations. Discover the key drivers of value and cost in post-consumer recycled materials, as well as the challenges and strategies for reclaiming high-quality recycled polymers for the carpet industry.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

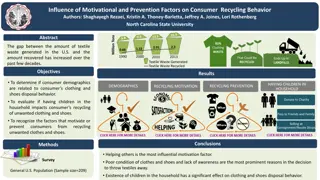

A Reclaimers Perspective on the Drivers of Value, Cost and Markets in Carpet Recycling Care 2022 Annual Conference Minneapolis, MN 6/1/2025 1

Post Consumer Recycled Value Marketplace Value depend on several factors. Polymer Type: Nylon 66, Nylon 6, PP, PET, PTT, PU, PVB, PVC Polymer Purity: The higher the purity of a single polymer, the higher number of markets that can accept/desire the product. Ash content is secondary to polymer homogeneity. Polymer Properties are critical. Examples include Intrinsic Viscosity (IV) for PET, Melt Flow Index for PP, Izod & Tensile for Nylon. Form: Melt Filtered Pellets, Densified Pellets, Fiber including fiber length and opened fiber. Color 6/1/2025 2

Cost Drivers for Reclaiming Carpet High face fiber Polymer purity requires additional equipment for backing fiber removal. Cut Pile vs. Continuous Loop There is greater polymer content per lb. in cut pile. Continuous loop requires up to 25% longer processing time to achieve same quantity of polymer output. Continuous loop runs slower and/or requires additional equipment to size reduce long fiber. Carpet tile processing requires alternate process and must be processed according to backing polymer type. PTT segregation from PET requires an extra sortation step. 6/1/2025 3

Recycled Polymer Markets for Carpet Advanced Chemical Recycling Markets Different chemical recycling processes have different polymer purity requirements. Polymer purity drives value. Different chemical recycling processes create different products with various values. Certain polymer contamination prohibits the ability to recycle chemically. Large volumes of alternative, non-carpet feedstock, exist in the market for all chemical recyclers. Very few chemical recycling plants are currently operating. 6/1/2025 4

Recycled Polymer Markets for Carpet Traditional Mechanical Recycling Markets Recycled polymer that can be used in the Circular Economy directly usually command high value. Traditional markets are extremely sensitive to polymer purity and homogeneity. Exceptions are composite and non-woven markets. Color markets have significantly lower demand, lower value and a plethora of alternatives. 6/1/2025 5

Development of Market Based Solutions Increasing the value of recycled carpet requires coordinated efforts between Mills and Reclaimers. How do we increase coordination? Do Mills understand the cost drivers of Reclaimers? How do we educate the Mills? Can Mills achieve performance, fashion and cost parameters while also considering end-of-life implications via design for recyclability? Other industries have engineers responsible for design for recyclability as part of their development process. Product Transparency is paramount in Mill/Reclaimer relationship. Deliver the bad news early so reclaimers can prepare and work solutions. 6/1/2025 6