Revised OSHA Hazard Communication Standard: Implications and Changes

Today's session highlights the revised OSHA Hazard Communication Standard (HCS) and its implications for chemical manufacturers, distributors, and cleaning service providers. The presentation covers the background of the HCS, the impact of the Globally Harmonized System (GHS) revisions, what remains the same under the GHS revisions, and what has changed in tactics such as hazard classification, SDS redrafting, labeling, and more. It delves into the obligations for chemical manufacturers and distributors, detailing the need to reclassify products, redraft SDSs, and redo labels by specific deadlines. Stay informed about the significant shifts in chemical hazard communication for a safer workplace environment.

Uploaded on Apr 13, 2025 | 2 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Bill Balek ISSA July 31, 2013

Todays Session Employee Education and Training Revised OSHA Hazard Communication Standard Due Dec. 1, 2013 Background March 20, 2012: OSHA issues final rule GHS revisions to Hazard Communication Standard

Background OSHA HCS Governs: Chemicals MSDSs Labels Employee education and training Purpose: Avoid chemical injury and illnesses

Background 1985: OSHA issues HCS Labeling, MSDS for hazardous chemicals 2001: Globally Harmonized System of Classification and Labeling of Chemicals (GHS) UN members agree to adopt GHS by 2008 2012: GHS Revisions to HCS

What remains the same under GHS Revs? Basic structure Manufacturers: Classify chemicals and provide SDS, labels to downstream customers Distributors: Pass SDS and labels downstream Employers: Employee education and training Avoid chemical injuries and illnesses

Whats changed? Tactics. Classification of hazards (Manufacturer) SDS: redraft to comport with new format, pictograms, etc. (Manufacturer) Labeling (Manufacturer) More prescriptive, uniform language Pictograms

Implications for Cleaning industry Chemical Manufacturers Distributors Cleaning Service Providers

Implications for Chemical Manufacturers Obligations that run to downstream customers Re-classify products Re-draft SDSs Re-do labels June 1, 2015

Implications for Distributors Obligations that run to downstream customers Send new GHS SDS (June 1, 2015) Ship products with new GHS labels (Dec. 1, 2015)

Implications for Employers Employers: Manufacturers, Distributors, Cleaning Service Providers Employee education and training New label elements New SDS format Dec. 1, 2013

New Labeling Elements Effective June 1, 2015 Distributors Dec. 1, 2015 Permissible to comply earlier

Safety Data Sheets (SDS) Formerly MSDS New 16 section uniform format Effective June 1, 2015 Permissible to comply earlier

Workers may see GHS labels, SDS soon OSHA requires employee training New label elements New SDS format Dec. 1, 2013 Ensure workers have info to protect themselves Understand GHS labels and SDS

Product identifier Signal word Hazard statement Pictograms Precautionary statement(s) Name, address, telephone number of manufacturer or other responsible party

Signal word Hazard statement Pictograms Harmonized label elements Based on hazard class and hazard category In general, manufacturer has no discretion

Product identifier Name of product Same as on SDS Signal word Indicates severity of hazard Danger: more severe hazards Warning: less severe hazards Only one signal word on the label Not all hazards have signal words

Hazard statement Describes the nature of the hazard Causes skin irritation Flammable liquid and vapor All applicable hazard statements must be on label Uniform (mandatory Appendix C)

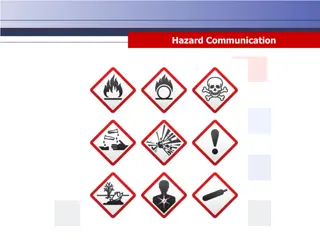

Pictograms Images that communicates the hazard Square on point Black hazard symbol White background Red border Red border minus hazard symbol NOT allowed

Skin corrosion, burns Eye damage Corrosive to metals

Flammable Pyrophorics Self-heating Emits flammable gas Self-reactive Organic peroxides

Oxidizer Gases under pressure

Carcinogen Mutagenicity Reproductive toxicity Respiratory Sensitizer Target organ toxicity Aspiration toxicity

Explosives Self-reactives Organic peroxides Acute toxicity (fatal or toxic)

Irritant (skin, eye) Skin sensitizer Acute toxicity Narcotic effects Respiratory tract irritant Hazardous to ozone layer Aquatic toxicity Non-mandatory

Precautionary Statements Recommended measures to prevent or minimize adverse effects from exposure , improper storage or handling What to do to prevent harmful exposure Wash thoroughly after handling Wear protective gloves What to do if there is harmful exposure If eye irritation persists, get medical advice

Name, address, telephone number of manufacturer or other responsible party Address City and state sufficient Telephone number New requirement

Pictogram Product Identifier Signal Word XYZ Cleaner Warning XYZ Manufacturing Co. Chicago, IL 312.123.4567 Causes serious eye irritation Hazard Statement Wash hands thoroughly after handling. Wear eye protection. Store in a cool dry place. First Aid If in eyes, rinse cautiously with water for several minutes. Remove contact lenses, if present, and easy to do. Continue rinsing. If eye irritation persists: get medical attention. Manufacturer Precautionary Statement

Make sure employees know How to go from label to SDS How to use label to Properly store product Work with product safely Avoid harmful exposure What to do in event of harmful exposure Where product has multiple hazards Multiple pictograms, hazard statements

Standardized 16-section format SDS must be presented in a consistent order Sec. 1: Identification Product identifier used on label Recommended use of the chemical Name, address and telephone number of manufacturer, importer or other responsible party Emergency phone number

Standardized 16-section format Sec. 2: Hazard identification Hazard class, and category (i.e., flammable liquid, category 4) Label elements: Signal word (i.e., Warning) Hazard statement (i.e., combustible liquid) Pictograms (none for flammable liquid, cat. 4) Precautionary statement Consistent with label / Heart of SDS

Standardized 16-section format Sec. 3: Composition/information on ingredients Information on chemical ingredients, trade secrets Sec. 4: First-aid measures Description of measures based on route of exposure Immediate medical treatment Sec. 5: Fire fighting measures Suitable and unsuitable extinguishing media Special hazards presented by the chemical in fire

Standardized 16-section format Sec. 6: Accidental release measures Personal precautions, emergency procedures Sec. 7: Handling and storage Precautions for safe handling and storage Any incompatibilities Sec. 8: Exposure controls / personal protection OSHA PELs, TLVs Appropriate engineering controls (ventilation PPE

Standardized 16-section format Sec. 9: Physical and chemical properties Appearance, pH, odor, flash point, vapor pressure, etc. Sec. 10: Stability and reactivity Chemical stability, possibility of hazardous reactions Conditions to avoid, incompatible materials Sec. 11: Toxicological information Routes of exposure, related symptoms, acute and chronic effects

Standardized 16-section format SDS must contain sections 12-15, but OSHA will not enforce the content for these Sections Sec. 12: Ecological information Sec. 13: Disposal considerations Sec. 14: Transportation information Sec. 15: Regulatory information Sec. 16: Date of preparation, last revision

Info must be presented in manner workers can understand Non-english speaking workers Illiterate Recommend: Keep record of employees trained Sign in log Training materials used Tests

If you would like a certificate indicating you have been trained consistent with the GHS HazCom Training requirements Email: bill@issa.com Subject Line: CERTIFICATE Short Test Upon passing test, certificate will be issued

ISSA Resources Detailed Summary: www.issa.com/ghshcs Manufacturers: Formulator Webinar Series Reclassification, SDS, Labels Tracy@issa.com: Formulator Webinar Employee Education and Training (Dec. 1, 2013) Webinar: July 31 Online training: www.issa.com/ghs Resources: www.issa.com/ghstraining

Questions??? Bill Balek, ISSA bill@issa.com 800.225.4772