Revolutionizing Engine Efficiency with Split-Cycle Technology

Todays engines operate at only 33% efficiency, but Split-Cycle Technology offers a game-changing solution. By dividing the standard engine's four strokes between a compression cylinder and a power cylinder, this innovative design maximizes thermal efficiency and power output. The unique advantages include longer power strokes, increased mechanical efficiency, faster combustion rates, and reduced emissions. With this groundbreaking approach, the Split-Cycle Engine promises significant gains in fuel efficiency and environmental impact, paving the way for a more sustainable future in the automotive industry.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

M.LOGANATHAN MECHANICAL ENGG

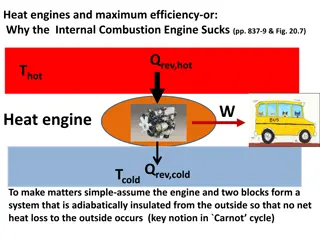

Todays engines operate at only 33% efficiency. This means that only 1/3 of the energy in each litre of fuel is used - the rest is lost through friction and heat. With over a billion engines currently in use worldwide, even small gains in efficiency will have huge impacts on the economy, dependency on foreign oil, and the environment.

Despite immense efforts over the past century, engine efficiency has remained the same. The heart of the internal combustion engine is a piston moving up and down in a cylinder connected to a crankshaft. Its simplicity makes improving performance almost impossible. Small improvements have proven difficult and large improvements have been considered impossible. While the industry struggles for gains in the 1% range; the design of the Split-Cycle Technology pushes engine efficiency and performance to an entirely new level.

The very concept of the split cycle gives way to certain in-built advantages: 1) The power stroke can be made longer than the compression stroke to over-expand the gas for increased thermal efficiency. 2) The compression piston diameter can be made larger than the power piston diameter to supercharge the gas for increased power. 3) The compression and power cylinders can be independently offset to almost any angle for increased mechanical efficiency.

The unique combination of maintaining a pre-charged pressure in the gas passage and firing after top dead center in the power cylinder produces several additional advantages. 1) An extremely fast combustion rate, 2) A further increase in thermal efficiency, and A significant reduction in nitrogen oxide (NOx) emissions.

The basic concept of the Split cycle Engine is to divide the four strokes of a standard engine over a paired combination of one compression cylinder and one power (or expansion) cylinder. These two cylinders perform their respective functions once per crankshaft revolution.

A common misconception is that twice as many cylinders are required. This is simply not accurate. Because this engine fires every revolution instead of every other revolution, the number of power strokes produced is equal to the power strokes produced by two of the conventional piston/cylinder designs. . A four cylinder engine would still have four cylinders. There would simply be two sets of paired cylinders instead of four individual cylinders.

In the configuration shown, an intake charge (Fig. 1) is drawn into the compression cylinder through typical poppet-style valves.

In this illustration, a check is used to prevent reverse flow from the crossover passage to the compression cylinder, and likewise a poppet-style valve (crossover valve) prevents reverse flow from the power cylinder to the crossover passage. The check valve and crossover valve are timed to maintain pressure in the crossover passage at or above firing conditions during an entire four stroke cycle.

Combustion occurs (Fig. 3) soon after the intake charge enters the power cylinder from the crossover passage. This means that the start of combustion occurs after the power cylinder passes through its top dead center position (ATC). Exhaust gases are than pumped out of the power cylinder through a poppet valve to start the cycle over again.