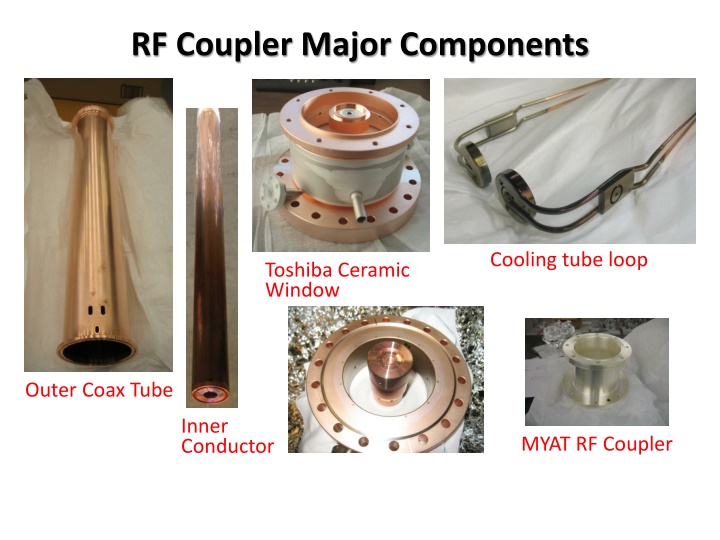

RF Coupler Major Components Cooling Tube Loop Toshiba Ceramic Window

"RF Coupler Major Components include Cooling Tube Loop, Toshiba Ceramic Window, Outer Coax Tube, Inner Conductor, TiN Coating, Fit-up Assembly, E-beam Welding, Remaining Assembly Tasks, and Scheduled Testing. The assembly process involves TiN coating of components, fit-up assembly before e-beam welding, alignment of loop to inner conductor, and final welds for bellows and connectors. A detailed schedule outlines the timeline for MTA Test Couplers assembly completion. Images provide a visual guide to the intricate assembly steps."

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

RF Coupler Major Components Cooling tube loop Toshiba Ceramic Window Outer Coax Tube Inner Conductor MYAT RF Coupler

TiN Coating of Components TiN coating of inside of outer coax tube and the end of the RF loop section

Fit-up Assembly Before e-beam Welding Assembly T handle for mounting center conductor Center conductors Canted spring RF seal in glidcop part between loop and outer conductor Center conductor

Fit-up Assembly Before e-beam Welding Assembly Outer conductor test fit to Toshiba RF window Alignment of loop to the inner conductor Outer conductor form tool

RF Coupler Remaining Assembly Tasks After fit up of assembly is complete it will go to the e-beam welding vendor E-beam welding of copper outer coax tube to stainless conflat flange

RF Coupler Remaining Assembly Tasks After returning from the e-beam welding Weld on bellows and lower bellow conflat flange Weld on water tube connectors Weld bellow lock out tabs

Schedule for MTA Test Couplers Assembly of components for e-beam welding by end of this week or early next week Deliver to e-beam welding vendor Up to 1 week to get assemblies back from e-beam welding Back at LBNL for final TIG welding of the bellows and cooling tube connectors Final vacuum check Pack and ship to Fermilab Assembly scheduled to be finished third week of March