RHIC Repair Work Planning and Safety Analysis

Explore the comprehensive safety work planning for RHIC repair by Frank Craner, covering job scope, hazard identification, hazard mitigations, accelerator safety evaluation, ODH controls, and changing conditions in the work environment. Ensure safety protocols are followed for a successful repair process.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

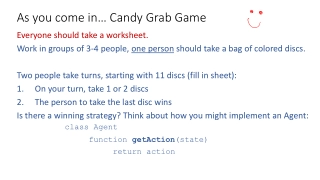

TAKE FIVE for Safety- Work Planning for RHIC Repair Frank Craner April 15, 2025

Job Scope (Initial Plan) Prior to Repair: Arcs 12/1 and 2/3 warmed up to 45K and allowed to drift warmer Arc 4/5 warmed to ambient temperature, with cryogen supply locked out VODH system disabled in the 4/5 arc Arcs 6/7, 8/9, and 10/11 remain cold at 4.5 K. Repair scope: Open RHIC Cryostat(s), Splice Can(s) Identify and Repair Shorted Bus Conductors, close Splice Can(s) and Cryostat(s) 2

Identification of Potential Job Hazards (Initial Plan) Activation Cryogenic Electrical Ergonomics Fumes/Mist/Dust Material Handling Oxygen Deficiency Vacuum Systems Welding/Cutting/Grinding/Brazing 3

Primary Hazard Mitigations (Initial Plan) LOTO of Hazardous Energy (Cryogen, Electrical, Instrument) Permit and fire protection mitigations for Hot Work Activities Exhaust Ventilation (ODH System) Postings/Barricades PPE for cutting 4

Accelerator Safety- USI Evaluation (Initial Plan) ODH System, including oxygen monitors with control of alarms and fans will remain enabled for entire RHIC ring. VODH module for arc 4/5 will be bypassed; modules for other arcs will not be affected. Arc 4/5 will not need VODH controls 5

RHIC Tunnel Sextant ODH Controls (As related to Initial Plan) Cryogenic System Condition Relative ODH Risk RHIC ASE Controls Helium at 293K (Ambient Temp) Low None 40K<Helium< 80 K Medium ODH Monitoring, Alarms, Ventilation, Automatic Isolation 3 Exhaust Fans per sextant minimum Helium < 40 K High Helium<80K Controls; PLUS: VODH Must be operable VODH Sensors must trip ODH Mitigations at 0.5 atm (nominal) 6

Changing Conditions (This Week) Identification of need for Adjustment to Cryogenic Isolation- Accelerator Safety USI Scaffolding to access point of work Material handling planning and evaluation 7

Conclusion Planning purpose to identify and mitigate issues related to worker safety and health, accident prevention, and compliance. Questions were raised early Reviews have been a team effort with input from several planners and Subject Matter Experts Frequent communication to address changing needs and conditions Work is affected by Accelerator Hazards and Non- Accelerator Hazards 8

![❤Book⚡[PDF]✔ Fool Me Once: Should I Take Back My Cheating Husband?](/thumb/20473/book-pdf-fool-me-once-should-i-take-back-my-cheating-husband.jpg)