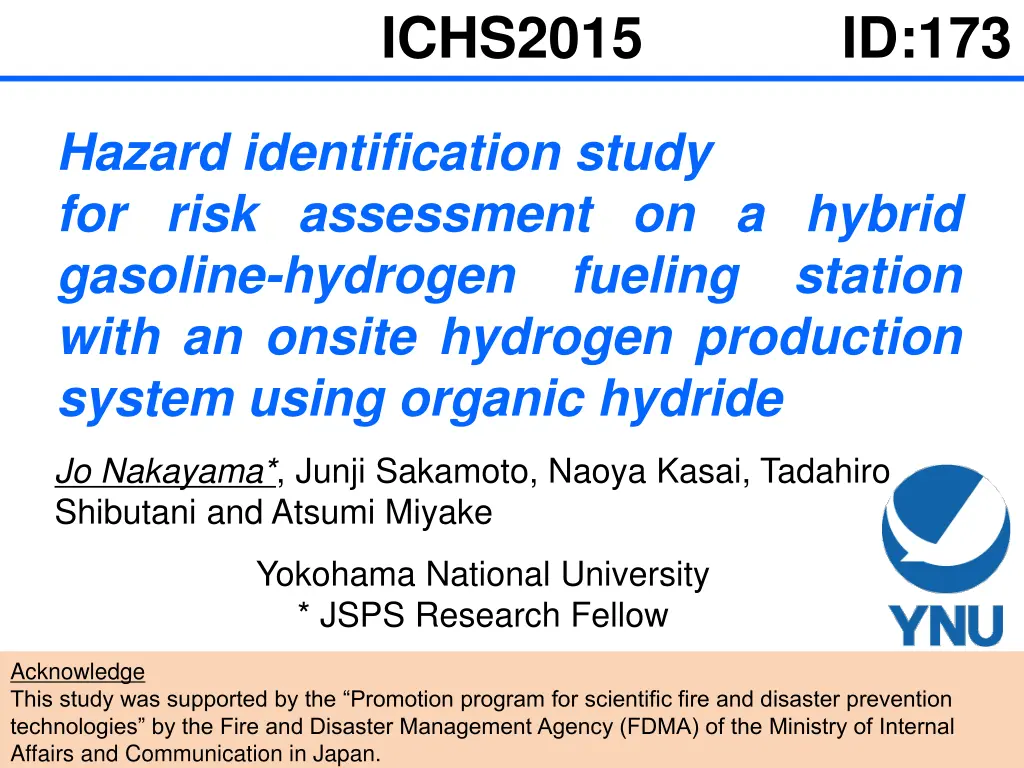

Risk Assessment on Hybrid Gasoline-Hydrogen Fueling Station with Onsite Hydrogen Production

Conducting a hazard identification study for risk assessment on a hybrid gasoline-hydrogen fueling station with an onsite hydrogen production system using organic hydride. The study aims to evaluate risks and contribute to a safer hydrogen society through qualitative and quantitative methods.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

ICHS2015 ID:173 Hazard identification study for risk assessment on a hybrid gasoline-hydrogen with an onsite hydrogen production system using organic hydride fueling station Jo Nakayama*, Junji Sakamoto, Naoya Kasai, Tadahiro Shibutani and Atsumi Miyake Yokohama National University * JSPS Research Fellow Acknowledge This study was supported by the Promotion program for scientific fire and disaster prevention technologies by the Fire and Disaster Management Agency (FDMA) of the Ministry of Internal Affairs and Communication in Japan.

Introduction Hydrogen fueling stations (HFSs) In California, 87 stations by 2020 In Germany, 400 stations by 2023 In Japan, 100 stations by 2015 In Japan, Planning to set hydrogen town as athletes village for 2020 Olympic in Tokyo. Accelerating station constructions and widely using FCVs. 1

Classification of HFSs Safety investigations Off-site On-site Organic hydride (Methylcyclo- hexane (MCH)) Compressed hydrogen Liquefied hydrogen LPG Stand- alone Hydrogen projects fueling stations Hydrogen Risk analyses using qualitative and quantitative methods1-3) No safety investigations Hybrid H2- gasoline Laws, regulations and codes Risk assessment on a hybrid H2-gasoline fueling station with an on-site hydrogen production system using MCH can contribute to a hydrogen society . 1. 2. 3. Kikukawa, S., et al., International Journal of Hydrogen Energy, 34, 2009, pp. 1135-1141. Kim, E., et al., International Journal of Hydrogen Energy, 38, 2013, pp. 1737-1743. Nakayama, J., et al., Proceeding of GCPS2015, Austin, 2015. 2

Risk assessment Process Lifecycle Conceptual Design Basic Design Detailed Design Research Operation Construction HAZID Study FMEA, HAZOP, ETA, FTA Effectiveness of Hazard elimination or reduction2) High Low HAZID Study Preliminary Hazard Analysis (PHA)1) is a method of qualitative hazard analyses at an early stage in process lifecycle. helps to detailed risk analyses at later stages. can effectively eliminate or reduce hazards for inherent safety. Purpose HAZID Study for identification and evaluation of risks involving with MCH system in the hybrid station. 1. ISO17776, Petroleum and natural gas industries Offshore production installations Guidelines on tools and techniques for hazard identification and risk assessment. Srinivasan, R., and Natarajan, S., Process Safety and Environmental Protection, 90, 2012, pp. 389-403. 3 2.

Analysis procedure 1. Definition of the model of a hybrid H2-gasoline fueling station using on-site hydrogen production system with MCH 2. Introduction of HAZID Study method 3. HAZID Study for identification scenarios 4. Risk evaluation by risk matrix 5. Representative scenario identification 6. Comparative evaluation analysis of MCH and existing LPG- typed hydrogen fueling stations. 7. Conclusions 4

A hybrid station model CH3 CH3 Pressurized hydrogen tanks? MCH < 1MPa underground tank? Dehydrogenation + 3 H2 reactor? 82 MPa Toluene underground tank? HE? MCH dehydrogenation HR : Hydrogen refinery HC : Hydrogen compressor PC : Pre-cooling system HE : Heat exchanger GLS : Gas-liquid separator? Collision guard ? Fire protection wall? HC? Fuel supply and Toluene recovery lorry position GLS? HR? PC? MCH Hydrogen Safety barrier? Water drain? Kerosene dispenser? Kerosene underground tank? Gasoline Maintenance Facility Canopy? Gasoline underground tank? Gasoline dispenser? Diesel fuel underground tank? Hydrogen dispenser? Office? Canopy? 5

A hybrid station model CH3 CH3 Pressurized hydrogen tanks? MCH < 1MPa underground tank? Dehydrogenation + 3 H2 reactor? 82 MPa Toluene underground tank? HE? MCH dehydrogenation HR : Hydrogen refinery HC : Hydrogen compressor PC : Pre-cooling system HE : Heat exchanger GLS : Gas-liquid separator? Collision guard ? Fire protection wall? HC? Fuel supply and Toluene recovery lorry position GLS? HR? PC? MCH Hydrogen Safety barrier? Water drain? Kerosene dispenser? Kerosene underground tank? Gasoline Maintenance Facility Canopy? Gasoline underground tank? HAZID Study Gasoline dispenser? Diesel fuel underground tank? Hydrogen dispenser? Office? Canopy? 5

Introduction of HAZID Study Hazard identification study (HAZID Study) - A qualitative accident scenario identification method - Scenarios are associated with GUIDEWORDs. Guidewords Natural hazard (24 types) ex. Earthquake, Tsunami, Typhoon External event hazard (15 types) ex. Airplane crash, Terrorism, Automobile collision Station layout hazard (3 types) ex. Evacuation Hybrid event hazard (6 types) ex. Gasoline leakage, Fire fighting Process hazard (21 types) ex. Combustible material, Explosion. specializing to detect hidden scenarios 6

HAZID Study sheet HAZID sheet consists of No. Guideword Cause Effect Risk level without safety measures Consequence, Probability and Risk Current safety measures Risk level with safety measures additional actions Scenario description for risk evaluation An example of HAZID sheet Risk level without safety measures Risk level with safety measures Additional actions No. Guideword Cause Effect Safety measures Consequence Probability Risk Consequence Probability Risk [1] Design (1) Material selection (2) Flame detector (3) Isolation valve (4) Fire protection wall (5) Safety barrier [2] Construction NA [3] Operation NA [4] Maintenance (1) Inspection (1) Toluene leakage (2) Dispersion (3) Ignition (4) Explosion (5) Loss of people and equipment Toluene leakage from pipe failure, corrosion, fatigue or hydrogen embrittlement Combustible material 1 5 3 3 3 1 2 7

HAZID study results No. (1) (2) (3) (4) (5) (1) MCH/ MCH/ 1 4 3 3 2 1 1 (1) (2) (3) (4) (1) MCH/ MCH/ 2 5 3 3 3 2 2 (1) (2) (3) (4) (5) (6) (1) The hybrid station has 314 accident scenarios involving with MCH and gasoline systems. 3 5 3 3 3 1 2 (1) (2) (3) (4) (5) (1) (2) / MCH/ MCH/ 4 4 3 3 2 1 1 (1) (2) (3) (4) (1) (2) / MCH/ MCH/ 5 5 3 3 3 1 2 (1) (2) (3) (4) (5) (6) (1) (2) / 6 5 3 3 3 1 2 (1) (2) (3) (4) (5) (1) 8 7 4 3 3 2 1 1 (1) (2) (3) (4) (1) 8 5 3 3 3 2 2 (1) (2) (3) (4) (5) (1) 9 4 3 3 2 1 1 (1) (2) (3) (4) (1) 10 5 3 3 3 2 2 (1) (2) (3) (4) (1) MCH/ 11 / / 4 2 3 2 1 1 (1) (2) (3) (1) MCH/ 12 / / 5 2 3 3 1 2 (1) (2) (3) (4) (1) MCH/ 13 / / 4 2 3 2 1 1 (1) (2) (3) (1) MCH/ 14 / / 5 2 3 3 1 2 (1) (2) (3) (4) (1) MCH/ MCH/ MCH/ 15 / / 4 2 3 2 1 1

Risk matrix Risk matrix without safety measures Probability 2 71 63 0 0 0 High Risk 1 0 0 0 0 0 3 4 0 0 0 0 0 Medium Risk Consequence 5 4 3 2 1 98 82 0 0 0 severity Low Risk Almost all risks are reduced by current safety measures. Risk matrix with safety measures Probability 2 0 27 19 2 0 1 3 0 0 0 0 0 4 0 0 0 0 0 46 risks remained as high regardless of operating safety measure. Consequence 5 4 3 2 1 19 95 126 26 0 severity 9

Representative common causes Regardless of operating safety measures, A gasoline car crashes into an operating MCH or toluene lorry. Pressurized hydrogen tanks? MCH MCH system underground tank? Dehydrogenation reactor? Toluene underground tank? A massive amount of gasoline is leaked and being spreading from an operating gasoline lorry for any reason. A gasoline pool fire affects the MCH system. HE : Heat exchanger GLS : Gas-liquid separator? Collision guard ? Fire protection wall? HE? HR : Hydrogen refinery HC : Hydrogen compressor PC : Pre-cooling system HC? Fuel supply and Toluene recovery lorry position Lorry position GLS? HR? PC? MCH or toluene disperses into the atmosphere while fire fighters are extinguishing a fire occurring at the MCH system. Safety barrier? Water drain? Kerosene dispenser? Kerosene underground tank? Maintenance Facility Canopy? Gasoline underground tank? New prevention and mitigation safety measures need to be added for risk reduction. Canopy? Gasoline dispenser? Diesel fuel underground tank? Hydrogen dispenser? Office? 10

Suggestion of safety measures Pressurized hydrogen tanks? MCH For prevention of collision at lorry position, a collision guard is needed while a lorry are operating. underground tank? Dehydrogenation reactor? Toluene underground tank? HE? HR : Hydrogen refinery HC : Hydrogen compressor PC : Pre-cooling system HE : Heat exchanger GLS : Gas-liquid separator? Collision guard ? Fire protection wall? needed to recover fuel. HC? Fuel supply and Toluene recovery lorry position GLS? HR? For prevention of spreading of gasoline pool around the lorry position, a water drain is MCH or TOL dispersions PC? Safety barrier? Water drain? Kerosene dispenser? Kerosene underground tank? Maintenance Facility For prevention and mitigation of escalation events while Gasoline underground tank? firefighting, a new tactics needs to be developed. Canopy? These additional measures can reduce risks. Gasoline dispenser? Diesel fuel underground tank? Hydrogen dispenser? Office? 11 Canopy?

Comparative evaluation of MCH and LPG MCH & TOL CH3 MCH & TOL 2 times LPG 1 time CH3 Lorry + 3 H2 MCH lorry H2 Storage tank Under- ground Over- ground H2 TOL lorry production system MCH or TOL is more likely to be leaked from faulty hose joints. A BLEVE of MCH or TOL may be occurred at a lorry position. LPG tank has a risk of a BLEVE. H2 TOL tank MCH tank LPG H2 LPG tank H2 production system LPG lorry Further analysis of incident involving MCH and TOL lorries. 12

Conclusions Purpose HAZID Study for identification and evaluation of risks involving with MCH system in the hybrid station. From the results of HAZID Study, HAZID Study identified 314 accident scenarios. 3 unique scenarios were revealed, and additional safety measures were suggested. The station was compared with a LPG-typed HFS, and remarkable points of the station were identified. Future works Detailed risk analysis of the MCH dehydrogenation system. Quantitative hazard analysis of incident involving lorries. 13