Role of Flame Retardants: Increase Safety, Prevent Fires

Almost all materials containing flame retardants can ignite to some degree, but these additives work to increase ignition temperature, prevent fires, decrease combustion rates, increase escape time for occupants, and reduce property loss. Learn about different types of flame retardants like halogen and non-halogen compounds and their effectiveness in fire prevention and safety.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Flame Retardants Glade Squires SPE TopCon 2024 omya.com

Role of Flame Retardants Almost all materials that contain flame retardants will ignite and burn to some degree However, Flame Retardants will . Increase the ignition temperature and, or make a material self-extinguish Prevent Fires From Starting Decrease the rate of combustion resulting in lower amounts of heat release to adjacent surfaces and objects Increase Escape Time For Occupants, Save Lives Reduce the rate of a fire spreading to avoid or delay flashover Increase Response Time, Reduce Property Loss 2 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

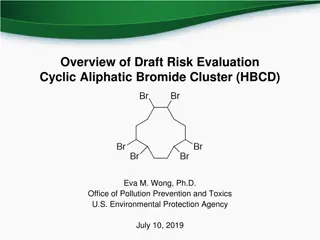

Types of Flame Retardants Phosphorus Elemental Red Phosphorus Phosphoric Acid salts Phosphorus containing organic compounds Bromine Inorganic Bromide salts Bromine containing organic compounds Chlorine Chlorine containing organic compounds Nitrogen Halogen Non- Halogen High Nitrogen content organic compounds Metal Hydroxides Absorb heat and release water upon decomposition Fluorine Inherently flame retardant polymers, i.e. TeflonTM 3 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Halogen Flame Retardants In general Bromine is twice as efficient as Chlorine on a molecular basis Additive Singular, Chlorine containing organic molecules Additive Singular, Bromine containing organic molecules Reactive Chlorine containing organic molecules with one or more chemically reactive groups Reactive Bromine containing organic molecules with one or more chemically reactive groups Chlorine Bromine Oligomeric Polymeric Long chain Chlorine containing organic compounds, PVC, Chlorinated resins Oligomeric Polymeric Long chain bromine containing organic compounds / Brominated resins 4 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Non-Halogen Flame Retardants Higher load levels required versus Halogen / Antimony systems Phosphorus Elemental Red Phosphorus Phosphoric Acid salts Phosphorus containing organic compounds Char forming chemical reaction creates insulation from external heat source and barrier for fuel to evolve into combustion zone Some vapor phase chemical reactions also occur Heat absorption leads to decomposition and release of Nitrogen by-products that dilute the Oxygen content in the combustion zone, produce intumescence when coupled with a char forming flame retardant Nitrogen Non- Halogen High Nitrogen content organic compounds Highly Endothermic Decomposition (absorbs heat) Metal Hydroxides Absorb heat and release water upon decomposition Magnesium Hydroxide - Mg(OH)2 Mg(OH)2 MgO + H2O @ 330 C Alumina Trihydrate Al(OH)3 2Al(OH)3 Al2O3+ 3H2O @ 230 C 5 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

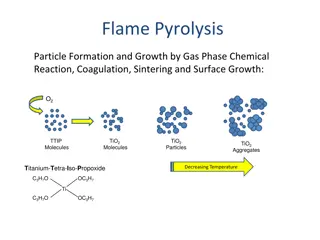

Antimony Trioxide Synergist Sb2O6 Halogen Flame Retardant systems exhibit their greatest efficiency and best economics when Antimony Oxide is added as a Synergist Demonstrated in an epoxy system that 15% Bromine by weight can be replaced with 5% Bromine and 3% Antimony Trioxide FR loading reduced by 7% Usually added at a 3:1 ratio of Halogen to Antimony with more rapid synergism shown with a 2:1 ratio Upon pyrolysis, HBr is liberated and combines with the Antimony Trioxide to form Antimony Tribromide and Antimony Oxybromide in the vapor phase These two Antimony derivatives donate Bromine atoms to free radicals to break the chain propagation of combustion 6 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Smoke Suppressants As a result of the efficiency of a vapor phase FR system and the rapid suppression of combustion, large amounts of unburnt fuel are present as smoke Zinc Borate is the most common smoke suppressant / synergist added to reduce smoke 2ZnO 3 B2O3 3.5H2O Promotes the formation of a char layer, which prevents the oxidation of carbon by limiting the available oxygen and suppresses smoke production Above 290 C, water of hydration is released, cooling the front of the flames and subtracting energy to the fire with an endothermic reaction. Suppressing higher levels of smoke in more challenging systems, Zinc Hydroxystannate or Zinc Stannate are used June 22, 2020 The addition of ATH can also help to reduce smoke in some systems 7 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Fire Fire consists of five distinct stages - heating, thermal decomposition, ignition, combustion and propagation HEAT FIRE FUEL AIR Mixing of fuel and air 8 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Flame Retardant Mechanisms Chemical Halogen + Antimony scavenging free radicals in the vapor phase breaking the chain propagation of combustion Phosphorus charring and Phosphorus + Nitrogen intumescence Metal Hydroxides absorbing heat and releasing water vapor Zinc compounds creating char in the condensed phase Physical Char insulating the substrate and preventing volatilization of fuel Nitrogen compounds released dilutes oxygen level in combustion zone Water vapor released, cooling and dilution of fuel and oxygen level in the combustion zone 9 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Flame Retardant Mechanisms Physical: Chemical: heat sink: endothermic decomposition of FR or endothermic reactions promotion; the result is decreasing temperature of the polymer and thus hindering flame propagation; x free radical scavenging, that is interrupting radical reactions which are responsible for flame propagation what slows down flame propagation or even stops char formation, that is promoting formation of a char layer on the polymer surface; then the surface is not susceptible to pyrolysis preventing the release of combustible gases; inert gas evolution: releasing of inert gases during FRs decomposition (e.g. H2O, CO2, NH3, hydrogen halides) dilutes combustible gas in the proximity of the polymer surface and thus impedes ignition and flame development; x intumescence: heated materials start to swell and expand, forming a protective layer; x acceleration of polymer decomposition promoting polymer melting, so that the molten zone separates the rest of the polymer from the flame zone; (Think about the behavior of a candle from which the wick is removed.) protective solid layer: FRs coatings form impermeable layer on the polymer surface which limits heat and oxygen transfer to the polymer and combustible gases from polymer to vapor phase. 10 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Physical and Chemical Processes of Combustion Halogen Antimony Nitrogen / Water Vapor Intumescence Charring Phosphorus / Nitrogen Metal Hydroxides https://www.fire.tc.faa.gov/pdf/05-14.pdf Polymer Flammability U.S. Department of Transportation, Federal Aviation Administration Authors - Richard E. Lyon and Marc L. Janssens 11 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Flammability Tests UL-94 (Underwriters Laboratories) HB, V-0, V-1, V-2, 5VA, 5VB HB = Horizontal Burn Test The three vertical ratings, V2, V1 and V0 indicate that the material was tested in a vertical position with two applications of the flame and self-extinguished within a specified time after the ignition source was removed The vertical ratings also indicate whether the test specimen dripped flaming particles that ignited a cotton indicator located below the sample 5VA and 5VB, vertical tests where the flame is applied five times 12 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization.

UL 94 UL 94 is a flammability standard for plastic materials, horizontal burning or vertical burning tests (HB V-2, V1, V-0) 13 February 19, 2018 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

UL94 Ratings 14 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Flammability Tests Limiting Oxygen Index Minimum concentration of oxygen expressed as volume percent in a mixture of oxygen and nitrogen that just supports flaming combustion of a material initially at room temperature Air is 20.95% Oxygen. Therefore, any material with an LOI less than 20.95% will burn in air and any LOI greater than 20.95% will self- extinguish 15 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization.

Limiting Oxygen Index, LOI Measured and reported as the percentage of oxygen needed to just sustain continuous combustion of a sample. The higher the LOI the lower the flammability. Air contains approximately 21% oxygen and therefore any material with an LOI of less than 21 will probably support burning in an open-air situation. Even though a material has a value of greater than 21, it would only need about 5% oxygen to undergo flaming combustion in a fully developed fire. Valuable tool since it is one of only a few tests where steady burning conditions can be replicated on a small scale. 16 February 19, 2018 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

ASTM E84 Flammability Test ASTM E84, UL 723, are also known as the Steiner Tunnel Test (developed by Albert Steiner in 1944), tests the surface burning characteristics of interior finishes and building materials, specifically of wall and ceiling materials. Tunnel is 24 inches wide by 24 feet long. Test specimen is 18 inches wide by 24 feet long mounted on the ceiling of the tunnel. Two burners at the front generate 89 kW of heat. Test measures two key characteristics, flame spread and smoke generation. Flame spread determines how fast a material will contribute to the propagation of a fire. Smoke generation determines how much smoke a burning material will contribute during a fire and can visibility be maintained for occupants to escape. 17 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

ASTM E84 Flammability Ratings Both the Flame Spread and the Smoke Development are indices and calculated from the data generated during the actual burn test. 18 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Cone Calorimeter Small scale test that measures very specific processes and stages of combustion and fire. Standard sample size of 100 x 100 mm and less than 50 mm thick. Heat flux of the ceramic cone heating element is typically set at 50 kW/m2to simulate the ignition burner heat fluxes in ASTM E84, Steiner Tunnel. Most important parameters measured are; Time To Ignition, Heat Release Rate, Peak Heat Release Rate, Total Heat Released, Mass Loss Rate and Total Smoke Produced These are all part of the various stages of a fire starting and propagating - heating, decomposition, ignition, combustion and propagation 19 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Cone Calorimeter Developed by the Fire Research Division at NIST in 1982 20 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Cone Calorimeter As A Development Tool The Cone Calorimeter is an effective small-scale test that can be used to predict the fire behavior of a composite material in a full-scale burn test such as the E- 84 Time and money saving development tool compared to the cost of running multiple full-scale tests Measuring the very specific processes and stages of combustion and fire on the Cone Calorimeter can be used to predict full scale fire behavior Effective tool to match fire performance of an existing, competitive flame retardant product or to improve fire performance and economics of an existing composite material 21 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization

Thank you! 22 June 22, 2020 This document contains proprietary information which shall not be used and disclosed without Omya explicit written authorization