Safety Measures for CTS Shops in Battle River School Division

Safety procedures such as lock-out, tag-out, and hazardous energy management are crucial in ensuring teacher, staff, and student safety in CTS (Career and Technology Studies) shops. The Alberta Occupational Health and Safety Code mandates isolation and control of hazardous energy to prevent potential hazards. Terminology like isolation, securement, lock-out, and verification play key roles in maintaining a safe work environment.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Lock Out Tag Out for CTS Shops Battle River School Division Revised 2018

What are we talking about? Ensuring teacher and staff safety when maintaining or adjusting shop equipment. Ensuring teacher, staff and student safety when equipment is defective, missing guards, or unsafe in any other way and should not be used.

Hazardous Energy Any energy or potential energy related to a piece of equipment that could pose a hazard to a person, examples include: Stored Energy (springs, tensioners, etc.) Electrical Energy Gravitational Energy Pneumatic Energy

Legislated Requirements The Alberta Occupational Health and Safety Code dictates isolation/managing the control of hazardous energy requirements in our jurisdiction. They include:

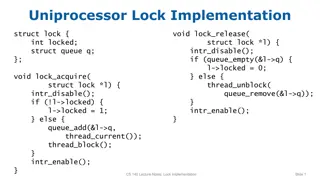

TERMINOLOGY Isolation is the act of physically preventing the release or transmission of an energy source. Securement is a means of ensuring isolation is not reversed or released, typically accomplished through the use of a lock-out device, or in certain circumstances through constant human surveillance. Lock-out is defined as the practice of using keyed security devices (locks) to prevent the unexpected start-up or release of stored energy by ensuring a means of securement remains in place. Lock-out tag is a tag used in conjunction with a lock-out to identify an item is locked out and by whom. Tag-out is the act of tagging a defective piece of equipment with information as to the defect in question to warn others of why it is not safe to use. Used only when the equipment can be put in a secure location to limit access to trusted personnel only. Not to be confused with a lock-out tag. Verification is a means of validating a specific method of isolation has been effective. Reactivation is the act of returning a machine to operational status after isolation or lock- out has taken place. Non-Owned Lock is any isolation or lock-out lock not owned by a person removing it. Absent Worker is a worker who has placed a lock on an isolation device but is not available to remove the lock.

BRSD PROCEDURE AND EXPECTATIONS Repairs and Adjustments When staff perform repairs or adjustments on equipment they must isolate the equipment to prevent accidental activation during the repair or adjustment. If the staff member in question is the only person in the area during this repair or adjustment they can do this by unplugging the machine. #note turning the switch to the off position would not be an adequate means of isolation. As long as the staff member in question is within view of the machines power source and can ensure no one plugs it back in while they are working on it, this means of isolation does not need to be locked out. If the staff member needs to leave the area and the machine is left in an unsafe condition to operate, or if the staff member can not maintain human surveillance on the type of isolation used, then the isolation must be secured (locked out).

BRSD PROCEDURE AND EXPECTATIONS Taking Equipment Out of Service If a piece of equipment is deemed unsafe in its current condition, it must be taken out of service. This can be accomplished in one of three ways: If the equipment or tool cannot be salvaged or repaired, it can be disposed of. If the equipment is small enough to be mobile, it can be moved to a secure area where no one other than the teacher can access it and it can be tagged out. If the equipment cannot be moved out of the workspace, it must be locked out to prevent anyone from using it.

BRSD PROCEDURE AND EXPECTATIONS Lock-Out A piece of equipment is locked out to ensure it cannot be activated, made operational or used by anyone other than the person performing the lock-out. The BRSD Safety Coordinator has evaluated the equipment in BRSD CTS shops and has found that major equipment can be isolated utilizing plug covers and locks. (equipment circulated to all shop teachers via courier) If you encounter a piece of equipment you cannot isolate or lockout using this method, please contact the Safety Coordinator.

BRSD PROCEDURE AND EXPECTATIONS Lock-Out Steps: Isolate the equipment from it energy sources (unplug it) Validate that the isolation is effective by performing a bump test (try to turn it on) If the equipment doesn't activate, continue to the next step. If it does activate, re-evaluate your isolation method to ensure you isolate all energy sources. Lock out the isolation method used (put a cover with lock-out tag on the plug end of the machine power cord and add a lock to it) Keep the key in your possession to ensure the equipment stays locked out.

BRSD PROCEDURE AND EXPECTATIONS Repair or Adjustment It may be necessary to coordinate with third parties such as the BRSD Facilities Department or a third party repair service to organize repairs. This may include facilitating the removal of the lock-out in place to allow for a competent repair person to trouble shoot or repair the equipment in question. Ideally this should only be done by the person who put the lock on, using the key for the lock. BRSD has a procedure for the removal of a non-owned lock under special circumstances mentioned later in this training slideshow.

BRSD PROCEDURE AND EXPECTATIONS Re-activation A piece of equipment can be re-activated or returned to operation once repairs or adjustments have been made and the activation does not pose a hazard to anyone. This is accomplished by removing the lockout device, removing the isolation method in place (remove plug cover and plug in machine) and testing the machine s operation to ensure it is safe for others to use.

BRSD PROCEDURE AND EXPECTATIONS Removal of a Non-Owned Lock In the event that the person who initiated a lockout is not available to remove the lock from a piece of equipment, and the work needing to be done cannot be reasonably rescheduled, parties involved can remove the non-owned lock by following these steps: The equipment is deemed by the Supervisor as safe to unlock, Removal is documented on the Lock-Out Device Removal Form (found in the BRSD Health and Safety Manual), Approvals in the form of signatures from any two of the following must be obtained: The Director of Facilities, The Assistant Director of Facilities, The Safety Coordinator, A Journeyman BRSD staff member whose trade scope relates to the type equipment that is locked out. Upon returning to work, the absent worker must be immediately notified of the lock removal verbally by their Supervisor and in writing by way of the form.

Scenario 1 What steps are required for isolation when a CTS teacher is changing the bit on a corded jig saw?

Scenario 2 What steps are required for isolation when a CTS teacher is replacing the blade on a band saw?

Scenario 3 What steps are required for isolation when a CTS teacher is adjusting the tool rest of a bench grinder?

Scenario 4 What steps are required for isolation when a scroll saw is not safe to use due to a damaged switch?