Side Channel Monitoring for Additive Manufacturing: Bridging Cybersecurity and Quality Assurance

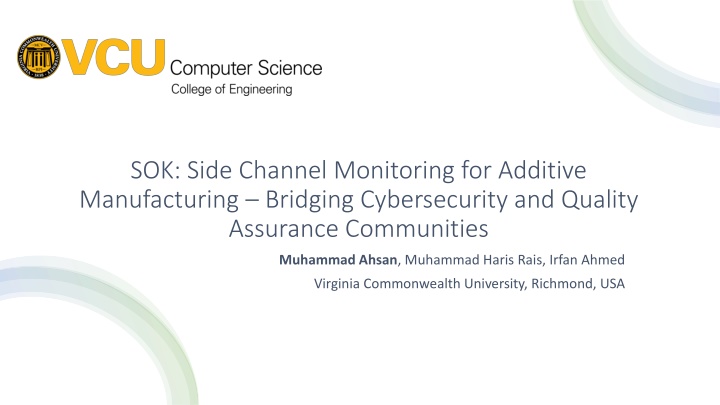

This study explores the significance of side channel monitoring in additive manufacturing processes, focusing on identifying physical data leaks and potential anomalies. It discusses various side channels, process anomalies, limitations, and industry 4.0 challenges. Future recommendations include tailored monitoring system designs and enhanced security solutions for a robust additive manufacturing environment.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

SOK: Side Channel Monitoring for Additive Manufacturing Bridging Cybersecurity and Quality Assurance Communities Muhammad Ahsan, Muhammad Haris Rais, Irfan Ahmed Virginia Commonwealth University, Richmond, USA

Fused Filament Fabrication Fused Filament Fabrication Fused Filament Fabrication is a type of Additive Manufacturing A material extrusion-based process Extruding a heated filament through a heated nozzle and depositing layer by layer to create a 3D object. Creating a CAD File CAD software Designing Designing STL Editor Software CAD to STL File Slicing Slicing G-codes from STL file Slicer Software 3D printer firmware Printing the object Printing Printing

Systematization Methodology Systematization Methodology

Side Channel Acoustics Thermal Laser Vibration Electric Current Optical Pressure Heterogeneous Sensors It refers to physical domain data that is being leaked from the AM process. Monitoring and techniques uses Side Channels. Total of 8 Side Channels are extensively researched literature. Detection in

Process Anomalies Process Anomalies These are the potential anomalies/defects that are being monitored using Side Channels. Three types Kinetic Thermodynamic Hybrid 12 process anomalies

Side Channel Limitations Side Channel Limitations and Challenges and Challenges Intrinsic limitation associated with each Side Channel Scope -> defines physical domain (Kinetic, Thermal) Intrusiveness Noise Sensitivity Calibration Complexity

Industry 4.0 -> per setup profile training. Research Research Challenges Challenges Self correcting close Loop monitoring system. Detection of low magnitude and low footprint attacks.

Future Recommendations Future Recommendations Use Case Specific Design of Monitoring System. Inbuilt Security Solutions Benchmarking Monitoring Techniques

Conclusion Conclusion - - QA vs Security QA vs Security QA monitoring is quality focused QA focused on printed part QA used for optimizing printing parameters QA monitoring systems has low precision QA covers broader set of anomalies One process anomaly at a time Security is deception focused. Security focus on detecting malicious modification process. Security focuses on printing process integrity Security systems accurate and precise in detecting anomalies Covers most of the detection surface in are more

Thank you!! Thank you!! Questions? Questions? Contact Information: ahsanm5@vcu.edu