Soil Amendments and Pathogen Risks in Animal Manure

Learn about soil amendments and the risks of pathogens in animal manure. Explore the sources of common pathogens like Salmonella and E. coli, and discover treatment options to mitigate these risks effectively.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

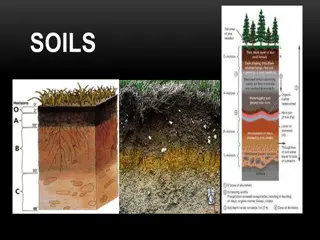

Module 3: Soil Amendments

Pathogens in Animal Manure All manures can carry human pathogens Some animals tend to be reservoirs for certain pathogens Many things can affect animals shedding pathogens in their manure Age Rearing practices Diet Season Environmental conditions Hepatitis A other places in addition to feces Match the pathogen with the animal: Pathogen Common source Salmonella These are all fecal-oral pathogens. One exception not on this list: Listeria monocytogenes Lm is found in soil and a lot of Birds (chicken) and reptiles and amphibians and HUMAN Cattle, pigs and feral swine, deer and HUMAN E. coli O157:H7 Giardia Beaver and HUMAN Toxoplasma Norovirus, Cats, rodents and HUMAN Only HUMAN SUPPLEMENTAL MATERIAL Bonus on slide 12 3

Spotlight on Definitions are important! Non-BSAAO Lower risk, not regulated by Produce Safety Rule Chemical, physical, vegetable Human Waste (Incl. Biosolids) May not be used, unless EPA allows BSAAO Regulated by Produce Safety Rule Practices vary with risk level: untreated or treated Definitions SUPPLEMENTAL MATERIAL Bonus on slide 13 Bonus 4

Other Treatment Options What other options are there? Whatever meets these characteristics: Controlled (measurable and repeatable) Validated (achieves microbial end points in 112.54(a) or (b)) Backyard composting? Probably not: no measurements Pasteurization? Probably Heat treated pelletized chicken litter? Probably Vermicomposting? Maybe. See preamble #277 Control: worms/manure ratio, other substrate, and time Validation: data on pathogen reduction Potential problem, is worm poop excreta (untreated BSAAO) by definition? MUST HAVE SUPPORTING INFORMATION TO BE TREATED SUPPLEMENTAL MATERIAL Bonus on slide 16 5

Spotlight on Treatment status Properly treated BSAAO are considered lower risk Controlled: Set ranges for conditions of treatment Scientifically validated: Reduces pathogens to acceptable levels NO SAMPLING for pathogens required Treatment conditions are validated to meet microbial standards Treatment SUPPLEMENTAL MATERIAL Bonus on slide 16 Bonus 6

Review risk assessment Chemical Fertilizer Is this a BSAAO? Yes No General pathogen risk? Higher Medium Lower SUPPLEMENTAL MATERIAL Bonus Bonus 7

Pre-Consumer Vegetative Waste Is this treated? Yes No Is this a BSAAO? Yes No General pathogen risk? Higher Medium Lower SUPPLEMENTAL MATERIAL Bonus Bonus 8

Blood Meal, Bone Meal, Fish Meal Is this a BSAAO? Yes No Is this treated? Yes No Blood Meal General pathogen risk? Higher Medium Bone Meal Lower Fish Meal SUPPLEMENTAL MATERIAL Bonus Bonus 9

Class A Biosolids Is this treated? Yes No Is this a BSAAO? Yes No General pathogen risk? Higher Medium Lower SUPPLEMENTAL MATERIAL Bonus Bonus 10

Hog Waste Lagoon Is this treated? Yes No Is this a BSAAO? Yes No General pathogen risk? Higher Medium Lower SUPPLEMENTAL MATERIAL Bonus Bonus 11

Where Were We? Risk analysis: Risk associated with non-BSAAO is lower, not regulated Exception is human waste, regulated by EPA Treatment status affects risk level and risk reduction practices Practices to reduce presence of pathogens Treatment of BSAAO Timing of application relative to harvest Practices to reduce likelihood of contact Method of application to produce-growing areas Storage and handling of BSAAOs SUPPLEMENTAL MATERIAL Bonus pre slide 17 Bonus 12

Spotlight on Slide 18 notes are key! TREATED: Zero day with proper application UNTREATED: Zero day with no contact during and after possible for your crop? UNTREATED: May use the NOP 90/120 day rule to reduce risk when contact with produce is foreseeable Application Intervals SUPPLEMENTAL MATERIAL Bonus on slide 18 13

SUPPLEMENTAL MATERIAL Bonus slide 24 14