SolidWorks Assembly Techniques and Tolerances for Manufacturing

Explore the world of SolidWorks assembly design, geometric dimensioning, tolerancing, and more. Learn about the importance of manifold vs. non-manifold parts, plus/minus tolerancing, and creating assemblies efficiently. Dive into practical tips for part insertion, assembly tree management, and component manipulation. Complete hands-on tutorials to master assembly design in SolidWorks.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

2 Design for Manufacturing Tolerances Manifold vs Non-manifold Part Influence on Assembly Assembly Steps

3 Geometric Dimensioning and Tolerancing Tolerances in a design tell the inspector how much variance or imperfection is allowable before the part must be considered unfit for use. Tolerance is the difference between the maximum and minimum limits on the dimensions of the part. Since parts are never perfect, a datum feature is used during inspection, to substitute for the perfect datum of the drawing. Datum features are simply referred to as datums

4 Plus / Minus Tolerancing When the part is produced in a manufacturing process, there will be errors. Even though most errors are undetectable to our eye, the variations can be picked up using precise measurements such as a CMM.

5 Manifold vs. Non-Manifold Think of it as Manufacturable vs Non-Manufacturable Can this part be manufactured?

6 Creating an Assembly

7 Inserting Parts Click Browse if parts do not show in dialog box

8 The Assembly Tree The design tree stores all information regarding the parts, mates, materials, and history of the assembly Very useful for manipulating parts

9 Move Component

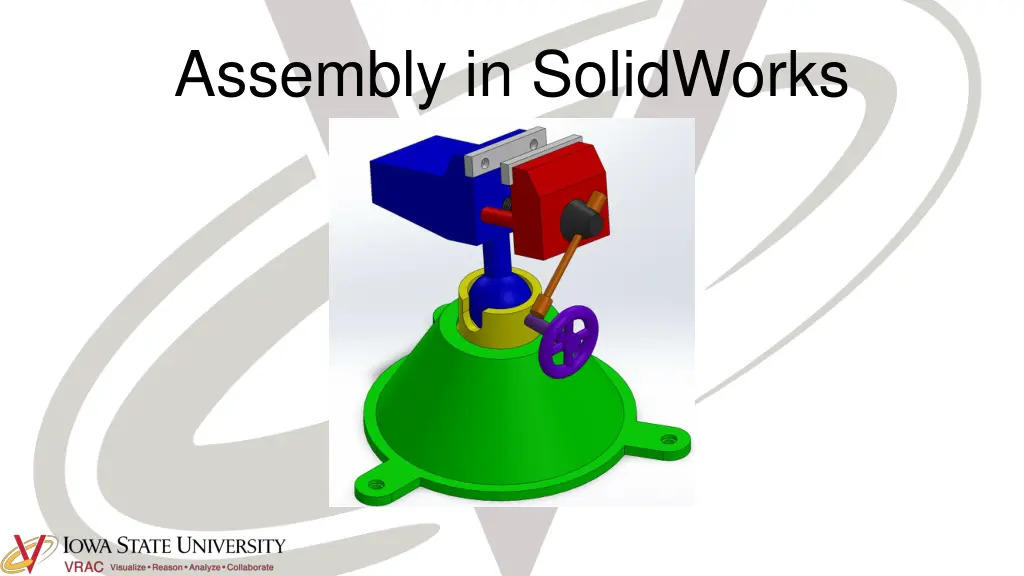

10 Activity Complete the Lesson 2: Assemblies tutorial Assemble the Vise - If your parts do not fit correctly, use the parts that are shared with you to make the assembly

11 Vice Assembly