Steel Corporation Advanced Analytics Results and Improvements

Explore the journey of United States Steel Corporation implementing advanced analytics models and achieving significant improvements in end-point detection, heat management, and trade-off tolerances for certain grades. Witness the transition from fixed limits to grade-specific trade-offs, resulting in reduced reblows and overblows. Follow the successful implementation of dynamic models and temperature control strategies leading to enhanced carbon and temperature management, ultimately optimizing steel production processes.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

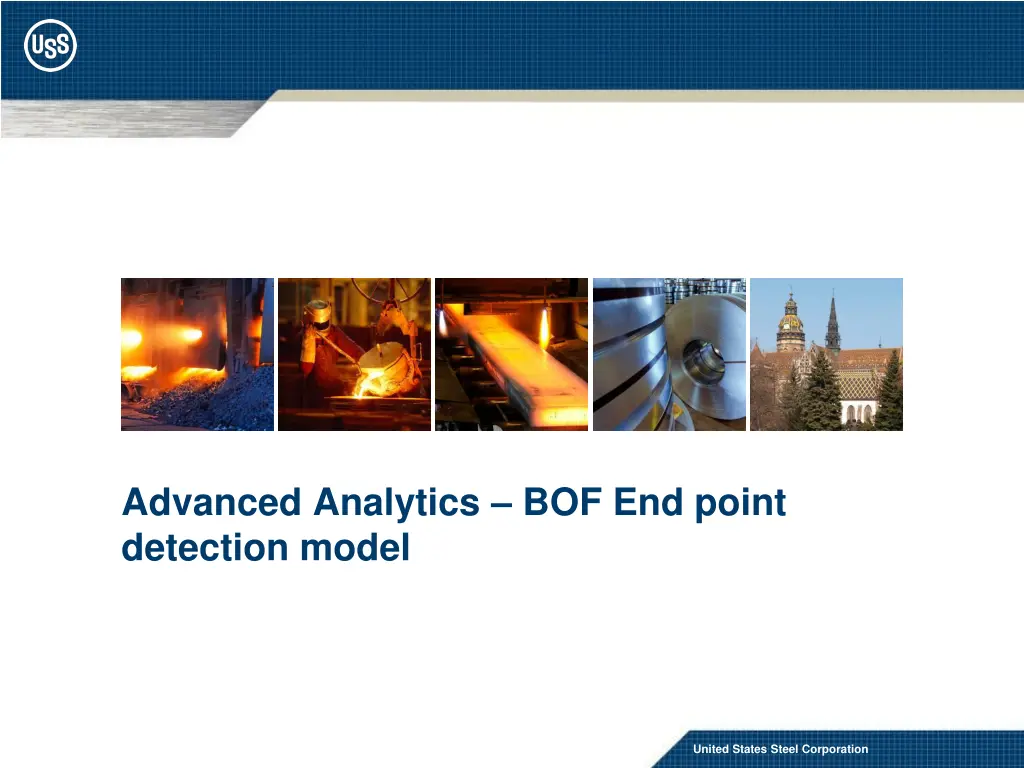

Advanced Analytics BOF End point detection model United States Steel Corporation

Initial state Stop by operator Recipe Blowing Model Static model 7.82% of heats were reblows 48.0% of heats were overblows 2 United States Steel Corporation United States Steel Corporation 2

From physical to digital Traditional programming Machine learning Inputs Inputs Outputs Program Program Outputs 3 United States Steel Corporation

Preliminary Data Analytics 1 dot is 1 heat Stop by operator Recipe Blowing Model Recipe model Dynamic model 2018 Model 537 22 250 Temperature Temperature 516 0 226 516 516 742 Carbon Carbon Source: USSK heat data 2018; Cost calculations based on data from USSK research 4 United States Steel Corporation

Actual Results K3 FY 2018 K3 3/2019 Temperature Temperature Carbon Carbon Reblows dropped from in avg. from 7.82% to 5.71% Overblows dropped in qvg from 48.0% to 38.19% 5 United States Steel Corporation

Moving from fixed C and T tolerances to more economic trade-off tolerances for certain grades New, grade specific borders Description From: Fixed limits for all heats To: Grade allowed trade-offs ~55% heats1 on reaches target temperature before target carbon Stopping when T is good for grades less sensitive on C Grade specification, for many of these, allows stopping heat before reaching target carbon Newly suggested stop ~30% of heats reaches carbon level before reaching temperature With low carbon, further blowing increases O2 activity, to be compensated by Al or coke Stopping earlier leverages chemical heat from Al and reduces addition of Al to compensate O2 When C is low, stopping to limit O2 activity Newly suggeste d stop 6 United States Steel Corporation