Supply Chain Strategies: QR and AR for Enhanced Operations

Explore Quick Response (QR) and Accurate Response (AR) strategies in supply chain management. QR focuses on speed and agility, optimizing inventory, agile manufacturing, and technology integration. Meanwhile, AR emphasizes precise operations with demand forecasting, inventory accuracy, quality control, order precision, and supplier reliability.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

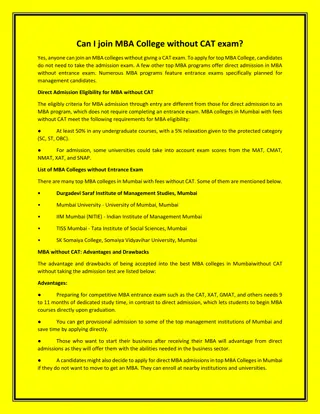

QUICK RESPONSE (QR) AND ACCURATE RESPONSE (AR)

QUICK RESPONSE (QR) Quick Response (QR) is a supply chain strategy aimed at reducing lead times, accelerating the order fulfillment process, and enhancing customer satisfaction. It primarily focuses on speed and agility in responding to customer demands. Key components of QR include: 1. Rapid Demand Sensing 2. Efficient Communication 3. Inventory Optimization 4. Agile Manufacturing 5. Technology Integration

QUICK RESPONSE (QR) 1. Rapid Demand Sensing QR relies on real-time data and demand sensing techniques to quickly identify changes in customer demand. This allows organizations to adjust production, inventory, and distribution plans promptly. 2. Efficient Communication Effective communication channels and collaboration between various stakeholders in the supply chain, including suppliers, manufacturers, and retailers, are critical for QR success. Clear and timely communication ensures that everyone is aligned and can respond rapidly to changes.

QUICK RESPONSE (QR) 3. Inventory Optimization QR aims to reduce excess inventory while ensuring that essential products are available when customers need them. Techniques like just-in-time (JIT) inventory management help in achieving this balance. 4. Agile Manufacturing Agile manufacturing processes enable organizations to produce goods efficiently in response to changing demand. Quick changeovers and flexible production lines are key elements of QR. 5. Technology Integration QR leverages advanced technologies such as RFID (Radio-Frequency Identification), IoT (Internet of Things), and AI (Artificial Intelligence) to enhance visibility, track inventory, and improve forecasting accuracy.

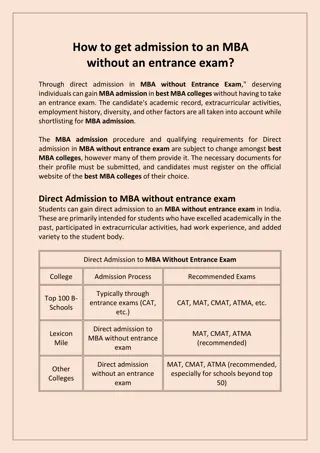

ACCURATE RESPONSE (AR) Accurate Response (AR) complements QR by emphasizing the precision and accuracy of supply chain operations. While QR focuses on speed, AR emphasizes the importance of delivering the right products in the right quantities at the right time. Key components of AR include: 1. Demand Forecasting 2. Inventory Accuracy 3. Quality Control 4. Order Accuracy 5. Supplier Reliability

ACCURATE RESPONSE (AR) 1. Demand Forecasting Accurate demand forecasting is crucial for AR. Organizations invest in sophisticated forecasting models and data analytics to ensure that they can meet customer demands with precision. 2. Inventory Accuracy Maintaining accurate inventory levels is essential to avoid stockouts or overstock situations. AR involves robust inventory management systems and regular audits to ensure inventory accuracy.

ACCURATE RESPONSE (AR) 3. Quality Control Quality control measures are paramount in AR to ensure that products meet or exceed customer expectations consistently. Organizations invest in quality management processes and continuous improvement initiatives. 4. Order Accuracy Order accuracy is a priority in AR. Organizations implement order management systems and technologies to reduce errors in order processing, picking, and packing. 5. Supplier Reliability AR relies on reliable supplier relationships to ensure the timely delivery of high-quality materials and components. Supplier evaluation and collaboration are essential components of AR.