Sustainable Process Improvement Project at LANXESS RUC-Site

This project idea aims to develop a robust waste water pre-processing technology for LANXESS RUC-site in Belgium, focusing on reducing zinc treatment, increasing recycling rates, and simplifying processes. The initiative outlines a future scenario involving membrane and ion exchange technologies, with potential cost and raw material savings. The impact includes significant reductions in zinc treatment, material savings, and process efficiency improvements.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

SPIRE Brokerage Event Sustainable Process Industry Project Idea Presentation Sarah Sangermann & Martin Riegels, LANXESS RUC SPIRE Brokerage Event, Brussels, 16thDecember 2013 1

Organization LANXESS Energizing Chemistry Sales in the year 2012 EUR 9.094 bn Employees worldwide approx. 17,500 Performance Polymers Advanced Intermediates Performance Chemicals Portfolio Global orientation 52 production sites worldwide LANXESS is one of Germany s most important providers of polymers and chemicals 2

Rubber Chemicals (RUC): a leading supplier of chemicals and additive solutions to a variety of industries Part of: Employees: Production Sites: LANXESS Performance Chemicals < 600 Kallo (Belgium), Brunsb ttel, Uerdingen (GER), Bushy Park (USA), Jhagadia (India) Facts Antidegradants Specialties: bonding agents, anti-reversion agents, fillers Products & Brands Accelerators Applications 3

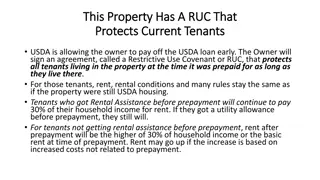

Project Idea Concept Current Situation of Production at RUC-site in Kallo, Belgium Waste streams contain large amounts of Mercaptobenzothiazole (MBT), some amines, Zn2+and other chemicals Complex pre-treatment in several tanks with sulfuric acid before biological waste water treatment Some recyclable fractions can be used again, but most are burned or abolished in the biology before the waste water is passed to the river 4

Project Idea Concept Future Scenario: Development of robust waste water pre-processing Membrane and/or ion exchange technology For large scale factories and small scale pretreatment plants Decreased amount for biological waste water treatment Higher recycling rate of components, e.g. MBT, bromide 5

Idea Impact Reduction of the amount of zinc having to be treated in the biological waste water treatment currently: around 430 kg/year possible reduction to 0 Recycling of MBT which is now burned or abolished and that could be used again in the process raw material savings: -10% Cost savings reduction of costs for sending certain components to the river Simplified Process Design in general 6

Existing Project Consortium Testing and implementation ECOSYNTH/Belgium Evaluation of the oxidation process MIONTEC /Germany Evaluation ion exchange technology 7

Looking for partners specialist in membrane technologies to remove selective organics from waste water specialist in alternative technologies to remove selective organics from waste water other companies having similar waste water problems 8

Contact details Sarah Sangermann LANXESS Deutschland GmbH Global Production & Technology Business Unit Rubber Chemicals Martin Riegels LANXESS N.V. Site Manager Rubber Chemicals Business Unit Rubber Chemicals Kennedyplatz 1 50569 K ln, Germany Phone : +49 221 8885 1390 Mobile : +49(0) 175 3008051 Sarah.Sangermann@lanxess.com Geb. 7633, Ketenislaan 2, Haven 1992 9130 Kallo, Belgium Phone: +32 3 2127127 Martin.Riegels@lanxess.com Lipnizki Jens LANXESS Deutschland GmbH Technical Application Membranes Liquid Purification Technologies Jenny Barbier LANXESS Deutschland GmbH Ion Exchange Resins Liquid Purification Technologies Kennedyplatz 1 50569 K ln, Germany Phone : +49 221 8885 2013 Jens.Lipnizki@lanxess.com Kennedyplatz 1 50569 K ln, Germany Phone : +49 221 8885 7288 Jenny.Barbier@lanxess.com 9