System Development Life Cycle and Reliability Testing Topics

A system comprises interconnecting components working towards a common goal. Understand the phases and testing methodologies involved in ensuring quality, reliability, and safety throughout the system's life cycle. Explore reliability testing at various levels and its significance in ensuring the fault-free and consistent performance of products. Delve into system-wide perspectives on reliability, covering aspects such as cost management, customer satisfaction, resource optimization, and product quality.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Chapter Five System Development Life Cycle and Reliability Testing Topics Introduction Quality, Reliability and Safety Understanding systems life-cycle Phases in reliability testing SDLC Models/Methodologies Reliability sequential testing Reliability testing at component, subsystem and system levels

Introduction A system is a set of components that interact to achieve a common goal System: a set of things working together as an interconnecting network; a complex whole. A system features a large number of interacting components whose aggregate activity is nonlinear

Industrial systems: Production process Supply chain and logistic operations QM (QMS) Maintenance management system Ergonomics, safety and health system innovation system, etc

In a system wide perspective, reliability involves almost all aspects related to the possession of a property: cost management, customer satisfaction, the proper management of resources, passing through the ability to sell products or services, safety and quality of the product.

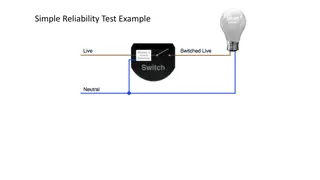

Reliability testing assures that the product is fault free and is reliable for its intended purpose. It also ensures that the quality and durability of a given product is consistent with its specifications throughout the product s intended lifecycle. This testing can be done at both the design and production levels.

At a system level reliability testing answers, how reliable is the system over time? In includes, but not limited to: facility testing - does the system provide all the functions required?" stress testing - can the system cope with heavy loads?" endurance testing - will the system continue to work for long periods?" performance testing - how good is the response time?"

recovery testing - how well does the system recover from failure?" serviceability testing - how maintainable is the system? documentation testing - is the documentation accurate, usable, etc." operations testing - are the operators instructions right?" regression testing - repeat all testing every time we modify the system!"

Quality, Reliability and Safety Reliability can be considered as Quality over time . Customers frequently use the terms quality and reliability . We need to understand what they expect. Measurement of reliability is related to failure rates, number of failures, warranty cost etc. Thus, reliability is experienced by the customers when they use the product.

Quality Level is measured in terms of defect levels (such as ppm) when the product is received as new. Quality and reliability both can have significant impact on Safety. Quality defects and failures both can adversely affect safety of user, bystanders and equipment. Some quality defects can lead to unreliable and/or unsafe product.

Some examples of how unreliabily can affect safety: Failure of automobile steering system, brake system, axles etc, can result in serious accidents. Short circuit in electrical equipment can result in a shock or death. Failure of safety valve in a pressure cooker, leakage of regulator of an LPG cylinder can result in an explosion. Poor reliability of a bridge can result in an accident and disaster However, all failures are not safety issues and all safety issues are not due to failures.

Type of Defects As Reliability Engineering is concerned with analyzing failures and providing feedback to design and production to prevent future failures, it is only natural that a rigorous classification of failure types must be agreed upon. Reliability engineers usually speaks of Failures Causes Failure Modes Failure Mechanisms

Main Causes of Failure Failure cause Description Function of the temporal and spatial distribution of the load conditions and of the response of the material. The structural characteristics of the component play an important role, and should be assessed in the broadest form as possible, incorporating also possible design errors, embodiments, material defects, etc.. Stress, shock, fatigue Operational variable that depends mainly on the specific characteristics of the material (thermal inertia), as well as the spatial and temporal distribution of heat sources. Temperature State of physical degradation of the component; it manifests itself as a result of aging phenomena that accompany the normal activities (friction between the materials, exposure to harmful agents, etc..) Wear Phenomenon that depends on the characteristics of the environment in which the component is operating. These conditions can lead to material degradation or chemical and physical processes that make the component no longer suitable. Corrosion

Reliability measurement is based on the failure rate. Some products (Non-repairable) are scrapped when they fail e.g. bulb Other products (Repairable) are repaired e.g. washing machine.

How Do Products Really Fail? Designed to fail Manufactured to fail Assembled to fail Screened to fail Stored to fail Transported to fail Operated to fail

How many hours, days or years will my product last in this type of environment? What s the life expectancy if it were exposed to these specific types of conditions? When it comes to answering these questions, the concept of time-based quality becomes relevant with regard to Reliability Testing. Incorporating the two facilitates the process of identifying and estimating a product s overall lifespan by exposing it to various environmental conditions. There are a number of tools and methods (statistical and non-statistical) available to estimate a product s lifespan, but which one should you use?

We are familiar with quality control testing, where a product is subjected to quality test checks to uncover defects. However, with Reliability Testing the objective is to test the endurance of a product under certain conditions, identify the failure rates and if applicable, propose preventative measures that can increase the product s reliability and lifespan.

The System Development Life Cycle Systems under development are engineered to satisfy the user's requirements, within determined cost, schedule and quality guidelines. It provides a structured approach to managing projects beginning with establishing the need for a systems development or maintenance effort, through development and deployment, and concluding with decommissioning of the system. It is crucial that system developers, customers, and all levels of management across functional areas adhere to the SDLC

The Systems development life cycle is a methodology that also forms the framework for planning and controlling the creation, testing, and delivery of an information system. The Systems development life-cycle concept acts as the foundation for multiple different development and delivery methodologies

SDLC Phase and Phase Activities 1. Determine System Needs Phase and its Activities 2. Define System Requirements Phase and its Activities 3. Design System Components Phase and its Activities 4. Build System Components Phase and its Activities 5. Evaluate System Readiness Phase and its Activities 6. Deploy The System Phase and its Activities 7. Decommission the System Phase and its Activities

SDLC Models/Methodologies A number of system development life cycle (SDLC) models have been created: Waterfall Incremental Agile

Reliability Test Program Reliability Testing like quality control testing is performed to provide confidence that the product meets its reliability requirements.

For a product to meet its reliability requirements is to go through a Reliability Test Program which consists of a series of integrated tests The Reliability Test Program integrates three types of tests: Reliability Development/Growth (RD/GD), Reliability Qualification (RQ) and Product Reliability Acceptance Test (PRAT).

Reliability Development/Growth Test The Reliability Development/Growth (RD/GD) test attempts to achieve certain reliability goals by identifying deficiencies and systematically eliminating them through a series of tests. (This type of testing is also known as the Test, Analyze and Fix test, or TAAF test.)

The two evaluation when conducting the RD/GD test. 1. Duane Method The Duane Method is a non-statistical method that uses graphical techniques. At each failure, the accumulated test time is calculated and the cumulative failure rate (total failures/total test time) is plotted against accumulated time. The growth rate is determined from the graph.

2. Army Material System Analysis Agency (AMSAA) Method The AMSAA uses statistical method assuming that reliability growth is a non-homogeneous Poisson process, where number of failures in an interval of time (or cycles, miles, etc., as appropriate) is a random variable distributed in accordance with the Poisson distribution.

Reliability Qualification Test During the Reliability Qualification Test phase, a product is tested under certain conditions to determine if it complies with its specified reliability requirements. If a product is in compliance then it s approved for production. Note: When planning a Reliability Qualification Test, it is best to ensure that the configuration is representative of the production units.

Product Reliability Acceptance Test Once a product is approved for production the next step is to perform the Product Reliability Acceptance Test (PRAT). The objective of a PRAT is to detect any inherent degradation in a product s reliability over the course of production. Note: During the PRAT, cumulative product operating time and product failures should be recorded and plotted on the chart for acceptance and rejection of the product.