TDR Parameter Discussion on Cavity Integration and Tuner Selection

In this technical document review (TDR), discussions on cavity integration, design parameters, and tuner selection are detailed. The focus is on confirming design parameters, defining plug-compatibility boundaries, and down-selecting tuners. Key areas covered include cavity specifications, tuning range, slow tuning hysteresis, and motor requirements for the tuner. The document emphasizes performance, procedures, plug-compatibility, and high-pressure vessel regulations related to the TESLA cavity and tuner components. Yellow boxes highlight areas yet to be specified, ensuring comprehensive coverage of specifications and requirements.

Uploaded on Mar 17, 2025 | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

LCWS11@Granada, 09282011 TDR parameter discussion on Cavity, Cavity Integration R. Geng, H. Hayano

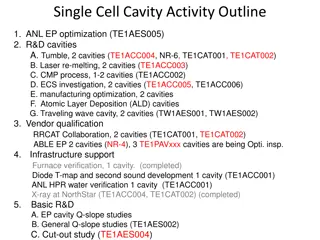

(1) TDR - Design Parameter discussion and confirmation (2) Plug-compatibility boundary definition (3) Tuner down-selection

TDR writing basement (1) Baseline: TESLA cavity with ILC-short length + TTF-III coupler *Baseline of Tuner : need to down-select, after performance & cost comparison (2) Performance: need to describe on RF, thermal, Mechanical, Electrical -performance (3) Procedure: need to describe on Fabrication, Treatment, Inspection, Test -Procedure (4) Plug-compatibility: describe clear boundary definition (5) High-pressure-vessel Regulation: need to describe how to clear it

(1) TDR Design Parameter discussion and confirmation

Cavity (TESLA-short) cavity specification item Frequency Number of cells specification unit and comments 1.30GHz 9.00cells Average 31.50MV/m 35.00+/-20%MV/m 0.8010^10 1.0010^10 Q R/Q (TESLA-short shape) further comments operational Vertical test at 35MV/m at 31.5MV/m TESLA-short HOM TESLA-short HOM Gradient Q0 RF properties HOM damping Short range wake Operating temperature Length 2.00K 1247mm TESLA-short length 70(iris), 78(beam pipe) Aperture mm Need to specify more detail press & EBW Alignment accuray Material Wall thickness 300.00um rms NiobiumRRR>300, fine-grain 2.80mm (TESLA-short shape) Al hexagonal Stiffness Flange/Seal system Physical properties Maximum overpressure allowed 2bar Lorentz force detuning over Flat-top at 35 MV/m 1.00kHz maximum Mag shield outside, decide later for precise number Because of TESLA-short Outer diameter He vessel 230.00mm * yellow boxes indicate not fixed , not specified yet Magnetic shielding outside

Tuner ( ??? ) tuner specification item Tuning range Hysteresis in Slow tuning specification >600 unit and comments kHz further comments <10 m step-motor use, Power-off Holding, magnetic shielding Motor requirement Gear-box match to driver unit, match to connector pin asignment, ex) 5 phase, xxA/phase, Motor specification decide later insdie 4K? / outside 300K? / inside 300K accessible from outside? need availability discussion, MTBF Motor location decide later mG at Cavity surface, average on equater mW at 2K Slow tuner Magnetic shielding <20 Heat Load by motor <50 do not conflict with GRP, 2-phase line, vessel support, alignment references, Invar rod, flange connection, cable connection, Mag shield Physical envelope Survive Frequency Change in Lifetime of machine could be total number of steps in 20 years, ~20 Mio. steps * yellow boxes indicate not fixed , not specified yet

Tuner ( ??? ) kHz over flat-top at 2K Tuning range >1 (LD and Lorentz detuning residuals Hz at 31.5MV/m flat- top <50 microphinics? or LD only?) :decide later match to driver unit, match to connector pin asignment, Actuator specification ex) low voltage piezo 0-1000V, decide later insdie 4K?/inside 4K accessible/inside 100K? accesible / inside 300K accessible from outside? Actuator location decide later Fast tuner mG at Cavity surface average Magnetic shielding <20 Heat Load in operation <50 mW do not conflict with GRP, 2-phase line, vessel support, alignment references, Invar rod, flange connection, Physical envelope number of pulses over 20 years, (2x109:operational number) Survive Frequency Change in Lifetime of machine >1010 * yellow boxes indicate not fixed , not specified yet

Coupler (TTF-III) Coupler condition specificationunit and comments >400kW for 1600 us >1200kW upto 400 us >600kW larger than 400 us further comments Operation Processing need after vac break, cool-down need after vac break, cool-down Power requirements Processing with reflection mode >600kW for 1600us in Test stand after installation, definition of power/pulse_width target are the same as 'Power Requirement' above. after installation, definition of power/pulse_width target are the same as 'Power Requirement' above. warm <50hours Processing time cold <30hours < 0.063W < 0.171W < 1.79W < 0.018W < 0.152W < 6.93W 2 yes tunableBy remote control 1-1010^6 compatible to TTF-III compatible to TTF-III compatible to TTF-III compatible to TTF-III >= 1 0at window 2K static 5K static 40 K static 2K dynamic 5K dynamic 40K dynamic # of windows bias capablity Qext Tuning range Position Flange waveguide support Vacuum pressure spark detection electron current detection temperature depend on tunability Heat loads /coupler Cavity vacuum integrety RF Properties Physical envelope Instrumentation >= 1at coax >= 1at window * yellow boxes indicate not fixed , not specified yet

Procedure specification (0) Flow-chart of cavity fabrication, treatment, inspection, and testing Fabrication Procedure (1) Material specification : Nb, Nb-Ti alloy, and Ti (2) Machining procedure : Nb, Nb-Ti alloy, and Ti (3) Pressing procedure (4) Treatment (handling, cleaning, etching) during fabrication (5) Welding procedure : Nb, Nb-Ti alloy, and Ti (5) Dumbbell fabrication procedure (6) End-group fabrication procedure (7) Welding up into cavity (8) Inspection specification (material scan, dimension, surface, frequency, leakage, etc) (9) Helium Tank fabrication, welding to cavity (10) Tools and equipment (11) Laboratory responsibilities

Treatment Procedure (1) Cavity handling specification (2) EP treatment specification (3) Rinsing treatment specification (4) Heat treatment specification (5) Tuning specification for 9-cell filed, straightness and HOM notch frequency (6) Surface inspection procedure (7) Surface repair procedure (8) Clean-room handling procedure (9) Attachment parts specification (Flange, gasket, antenna, pickup, etc) (10) Tools and equipment for treatment (11) Laboratory responsibilities

Test Procedure (Vertical Test) (1) Vertical Test procedure (2) Support fixture specification (3) Cryostat specification (4) Instrumentation specification (5) Tools and equipment (6) Laboratory responsibilities

ILC TDR Cavity Parameters Rongli Geng Jefferson Lab & GDE LCWS11 September 26-30, 2011, Granada, Spain LCWS2011, 9/26-30,2011, Granada, Spain 12 Rongli Geng

Cavity Design TTF shape ( TESLA-Short type ) LCWS2011, 9/26-30,2011, Granada, Spain 13 Rongli Geng

Cavity Fabrication High purity niobium Material specification ( RRR > 300 ) Cavity fabrication: Press & EBW LCWS2011, 9/26-30,2011, Granada, Spain 14 Rongli Geng

Cavity Processing Processing recipe and preparation sequence BCP+EP1+800C+EP2+120C Update recipe according to recent R&D result Update preparation sequence Re-processing strategy and recipe Decision point Without helium tank or with helium tank? Branching criterion Field emission limit -> re-HPR Quench > 25 MV/m -> re-EP Quench < 20 MV/m -> mechanical polishing LCWS2011, 9/26-30,2011, Granada, Spain 15 Rongli Geng

Cavity Performance Specification 35 MV/m +/- 20% Q0 >= 8E9 2 K LCWS2011, 9/26-30,2011, Granada, Spain 16 Rongli Geng

Field Emission Need to be defined ( for example; < 1mR/h (10uSv/h) at 31.5MV/m in VT however, we need justification of this criteria ) LCWS2011, 9/26-30,2011, Granada, Spain 17 Rongli Geng

Alternate Cavities & 1 TeV ILC Shapes Low-loss Re-entrant Low-surface-field Material Large-grain (Q0) Nb-Cu clad material (gradient) Operating temperature 1.8 K or 2 K Long-term R&D Thin film coated cavities w/ materials beyond Nb LCWS2011, 9/26-30,2011, Granada, Spain 18 Rongli Geng

RDR TTF design EBW EP1+800C+EP2+120C TDR TTF design EBW Update procedure Re-processing strategy 35 MV/m +/- 20% Q0>=8E9 Field emission 2 K Low-loss shape Re-entrant shape Low-surface-field shape Cavity design Cavity fabrication Cavity processing Cavity performance requirements Operating temp. Alternative cavities 35 MV/m Q0 >=8E9 2 K Low-loss shape Re-entrant shape Large-grain material 1 TeV ILC - LCWS2011, 9/26-30,2011, Granada, Spain 19 Rongli Geng

Cavity boundary BCD: TESLA-short cavity cavity boundary (1) beam pipe port flange ( beam pipe diameter ) (2) coupler port flange ( port pipe diameter ) (3) 4 support tabs (4) He pipes

Input coupler boundary BCD: TTF-III coupler input coupler boundary (1) cavity port flange ( port diameter ) (2) cold/warm part interface flange (3) cryostat vessel flange (4) waveguide flange

(3) Tuner down-selection Baseline of tuner is not yet decided. Then, we had a tuner test result at S1-Global. Now the time of down-selection, based on (a) Performance comparison by S1-Global results (b) Cost comparison We need to develop comparison tables.

High-pressure-vessel Regulation Regulation application for only cavity helium vessel -> small volume (small P*V value) made application more simple Nb, Ti at 2K use ; not a matter (KEK case) Still we need to evaluate pressure-stress calculation, welding record and inspection, and pressure test. This is a calculation example

Cost down The specification should include a room for cost down. For example ; ( Just an idea ) Make Nb material -> 2.8mm sheet and make cell by press, make pipes by deep-drawing and burring. Make Nb HOM antenna by press-cut from sheet material, Make Nb-Ti flange by press-cut from sheet material, Make number of welding minimum Make machining minimum Make one parts fabrication in one company Make press-cut process in the material company